Defelsko D Advanced 200D3-E Ultrasonic Coating Thickness Gauge Positector200 series Advanced

SEDefelsko D Advanced 200D3-E Ultrasonic Thickness GaugeSPEC

Defelsko D Advanced 200D3-E Ultrasonic Thickness GaugeDetails

Defelsko D Advanced 200D3-E Ultrasonic Thickness GaugePacking list

- SKU

- NB001496

- Measurement range

- 50 ~ 7600µm

- Probe style

- Split probe

- Lower limit of pipe measurement

- 500µm

- Measurement error

- ± (3% H + 20) μm

- unit system

- μm/mils

- Storage Capacity

- 100000 Measured values, 1000 groups

- Statistical function

- Average, standard deviation, Min/Max Film thickness and number of readings

- Standards

- ASTM D6132,ISO 2808

- Display

- Color LCD

- Operating language

- English, Chinese

- Interface

- USB

- Application software

- Yes.

- Protection level

- Resistant to solvents, acids, oils, water and dust

- Power

- 3 * 7 battery

- Host size

- 127 x 66 x 25.4 mm

- Weight

- 137G (without battery)

- Application

- Thick soft coatings such as polyurea, asphalt, neoprene, very thick polymers, etc

- calibration standard

- Defesko STDP1

Overview of the Defelsko Ultrasonic Coating Thickness Gauge

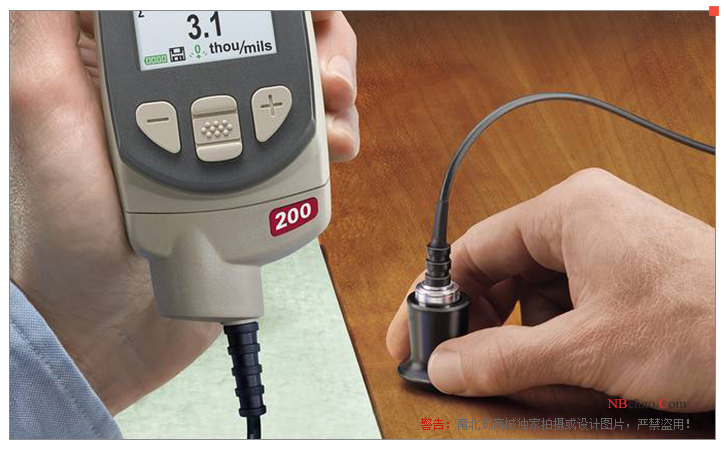

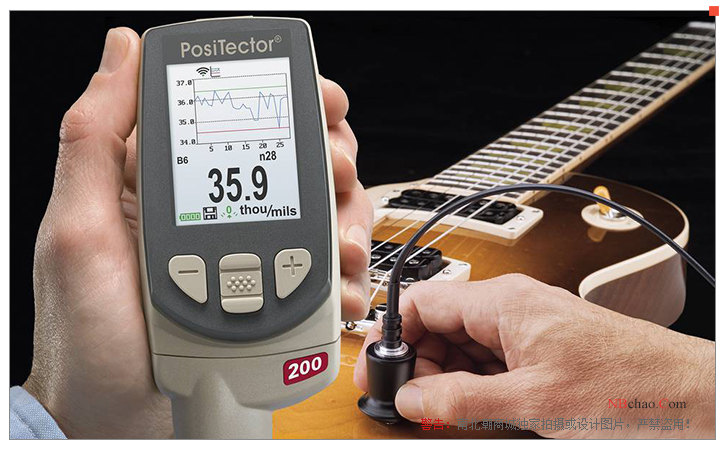

United StatesThe Defelsko Positector 200 Ultrasonic Coating Thickness Gauge is available in three different applications, the Defelsko D Advanced 200D3-E Ultrasonic Coating Thickness Gauge isAdvanced version of the Positector 200 series ultrasonic Thickness Gauges, ultrasonic coating Thickness Gauges for measuring thick and soft coatings such as polyurea, asphalt, neoprene, very thick polymers, etc.,D Advanced 200D3-EThe thickness range of the measurement is 50~7600 microns, which is in accordance with the thickness standard Defelsko STDP1.

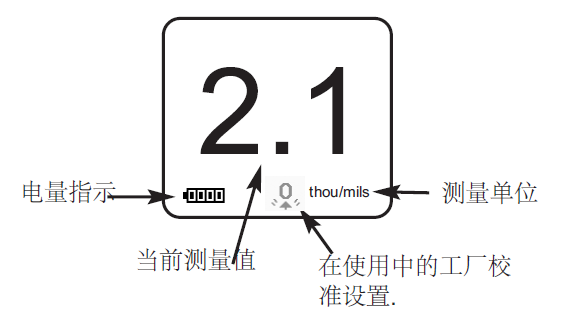

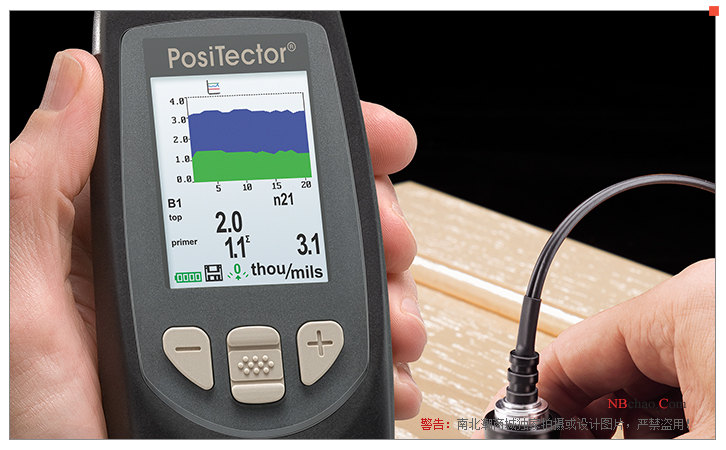

Typical screen display of a Defelsko Ultrasonic Coating Thickness Gauge

Benefits of the Defelsko Advanced Ultrasonic Coating Thickness Gauge

The Defelsko D Advanced 200D3-E ultrasonic coating Thickness Gauge can be used to measure total coating thickness or to measure up to 3 layers of individual thickness in a multi-coating system. It is also possible to output diagrams that facilitate detailed analysis of the coating system.

Defelsko Ultrasonic Coating Thickness Gauge Features

1. High durability

● Resistant to solvents, acids, oils, water and dust

● The rubber sheath with belt buckle provides shock absorption and protection

2. Easy to operate

● Ready-to-use – no calibration adjustment is required for the vast majority of tests

● AdoptionMenu-based navigation with one-handed operation

● Two-color indicator light, can still be used normally in noisy environments

● The RESET restart feature allows for a quick factory reset

3. Accurate measurement

● Ultrasonic coating Thickness Gauges are traceable to NIST's calibration proofs

● Sensitive sensors provide fast, accurate readings

● Proven non-destructive ultrasonic thickness gauging technology meets ASTM D6132 and ISO 2808 standards

4. Widely used

● The PosiTector mainframe is highly versatile, with PosiTector 200, 6000, SPG, DPM, and UTG probes all available and easy to replace. An ultrasonic coating Thickness Gauge can be transformed into a surface profiler, dew point meter or ultrasonic wall Thickness Gauge

● Mil/micron units can be switched freely, and multiple languages are available

● The high-contrast backlit display is convenient for operation in bright or dim environments

● It has an inverted display function, which is convenient for flipping the reading and operation when measuring

● Use alkaline batteries or rechargeable batteries (built-in charger)

5. Powerful

● Defelsko D Advanced 200D3-E Ultrasonic Coating Thickness GaugeMean, standard deviation, min/max thickness and number of readings can be continuously displayed/updated.

● It can store 100,000 readings and 1,000 packets.

● Screenshots - Record and store screen images for easy archiving and browsing.

● Quickly connect to your computer via the USB port for continuous power supply.

● PosiSoft USB Driver - Use a regular PC/Mac browser or explorer to access stored readings and charts without the need for software.

● Each stored data is marked with a date and time.

● It can be operated with PosiSoft.net software.

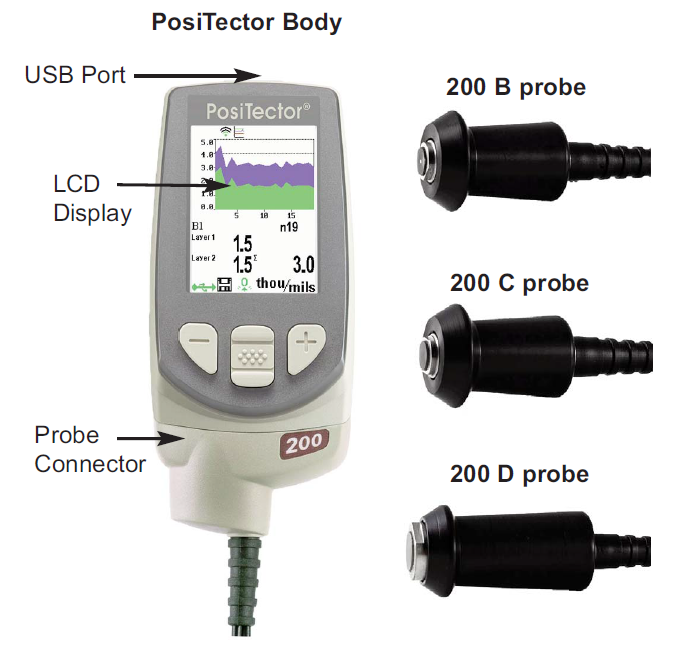

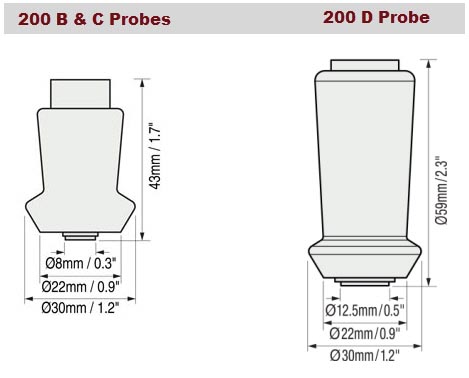

Structural diagram of a Defelsko ultrasonic coating Thickness Gauge

D Advanced 200D3-E Ultrasonic Coating Thickness Gauge Probe

Defelsko Ultrasonic Coating Thickness Gauge Display

- 1Principle and Application Analysis of Coating Thickness Gauge

- 2Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 3Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 4GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 5ASTM D 6132-2020《Destructiveness measurement of dry-film thickness of organic coatings applied to concrete》

- 6ISO 2808-2007《Paints and varnishes - Determination of film thickness》

- 7JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 8ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》

D Advanced 200D3-E

D Advanced 200D3-E