WENTAI FET-99S Intelligent digital eddy current Flaw Detector with installation training

SEWenTai FET-99S Eddy current Flaw DetectorSPEC

WenTai FET-99S Eddy current Flaw DetectorDetails

WenTai FET-99S Eddy current Flaw DetectorPacking list

- SKU

- NB016258

- Frequency range

- 64Hz~2MHz

- Gain range

- 0-48Db, step distance is 0.5db

- phase

- 0-360 degrees, 1 degree step (automatic phase, amplitude analysis function)

- Automatic zero correction system

- Zero correction interval can be set

- Alarm function

- Different styles of alarm area settings can be applied to various modes

- gain ratio

- 0.1~10.0

- Probe adaptation

- Adapt to various probes: such as external pass-through, swirl/spin, etc

- Detection speed

- 1m/min~360m/min

- Display mode

- Display modes: Impedance, Time Base

- Display mode

- Solid line, blanking

- blanking display coefficient

- 1~100

- Display

- liquid crystal display

- Standby power consumption

- < 10W

- Operating temperature

- -15~55℃

- Storage temperature

- -20~60℃

- Relative Humidity

- Not more than 85%

- Operating Voltage

- AC220±10V

Introduction

FET-99S intelligent digital eddy current flaw Detector is suitable for on-line and off-line flaw detection of aluminum tubes, aluminum rods, copper wires, aluminum wires, stainless steel wires and steel wires, and can be used for automatic flaw detection of other mechanical parts. The instrument adopts the latest digital electronic technology, eddy current technology and microcomputer technology, which is not only easy to debug and operate, but also has reliable, stable and sensitive flaw detection performance.

FET-99S has a relatively independent test channel, which can drive different types of detection probes, or combined probes composed of absolute and differential coils. The detection channel simultaneously collects data and is used to detect metal pipes, wires, and rods. Longitudinal cracks and transverse defects (such as splines) that occur during production. When used for on-line detection of wire rods, FET-99S has high sensitivity to axial defects such as dark gaps, open cracks, and pores.

The FET-99S flaw Detector has a test frequency range of 64 Hz to 2 MHz, which can adapt to the testing requirements of various metal wires, and because it adopts a fully digital design, it can establish multiple standard testing procedures or expert systems in the instrument, which is convenient for users Called when the product specification is changed.

The FET-99S can be connected with a through-type probe with a very low coupling gap requirement, and can also be connected with a combined plane probe or saddle-type probe that is only the size of a cigarette box.

Functional technical characteristics

1. Single station and single channel

2. Gain: 0-48db, step distance is 0.5db, frequency range: 64Hz-2MHz34,

3. Phase: 0-360 degrees, step distance is 1 degree

4. Independent optional frequency

5. Different styles of mode settings

6. Automatic phase and amplitude analysis function

7. Automatic zero-calibration system: the zero-calibration interval can be set

8. Different styles of alarm area settings can be applied to various modes

9. Gain ratio (Y/X): 0.1-10

10. Automatic screen clearing/tracking impedance display

11. It has the functions of detection signal playback, access, etc.

12. Fast analog/digital electronic automatic balance and dynamic tracking filter

13. The operation interface is simple and intelligent, easy to operate

14. Adapt to various probes: external pass-through

15. It is suitable for off-line quality inspection of metal pipe and rod production plants

16. Quick Numbers

17. Unequal amplitude and asymmetric phase alarm area setting

18. Multiple display methods: impedance, time base

19. Digital filtering

20. Sound and light alarm output

21. Automatic balance time

22. Internal and external clock selection

23. It can store a large number of various testing programs and testing data

24. Eddy current signal playback expansion function

25. Automatically record and display defects

26. Display mode: solid line, blanking

27. Blanking display coefficient: 1~100

28. Cartesian coordinate system and polar coordinate system background selection

29. Automatic calendar, time display

30. Liquid crystal display

31. Power supply: 220V (-20% ~ +20%)

32. Analog electronic balance

33. Measure the amplitude, phase and digital value of defects

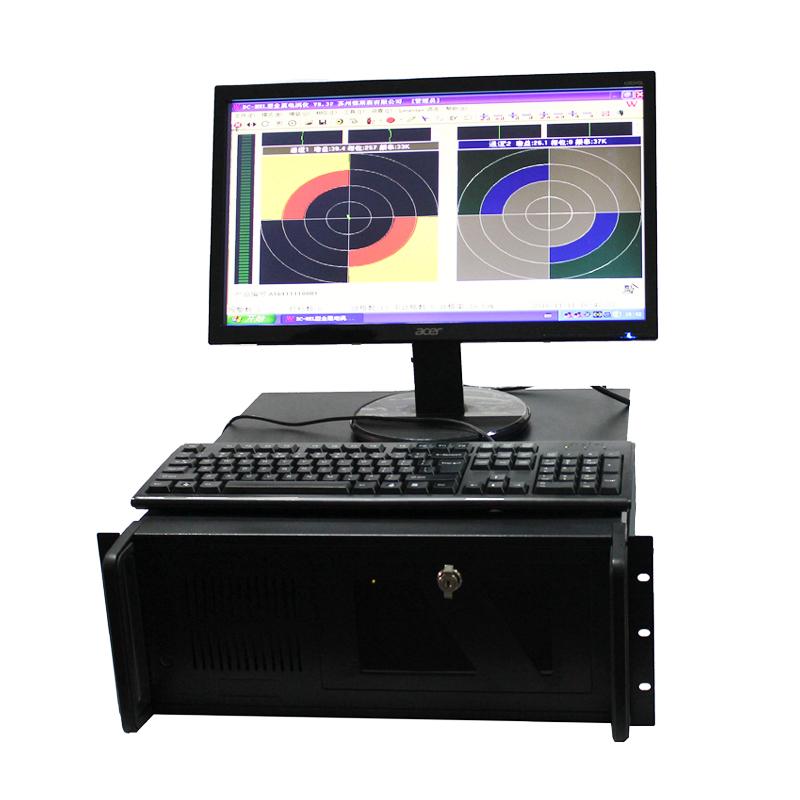

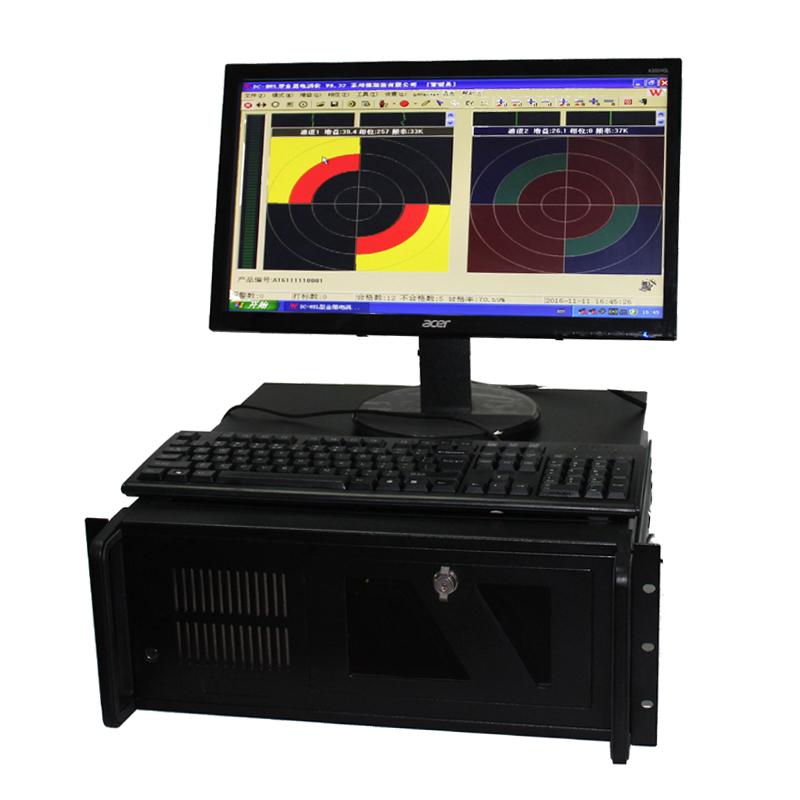

Schematic diagram of detecting no defects Clutter signal (below) | Schematic diagram of detecting defects Injury signal (below) |

|  |

Process description

1. Put the product on the rotating tooling;

2. The probe is attached to the surface of the workpiece, and the product moves forward with the rotating tooling image, and the probe detects the scanned product surface;

3. Automatic alarm when there is a defect;

4. No alarm when there is no defect

FET-99S

FET-99S