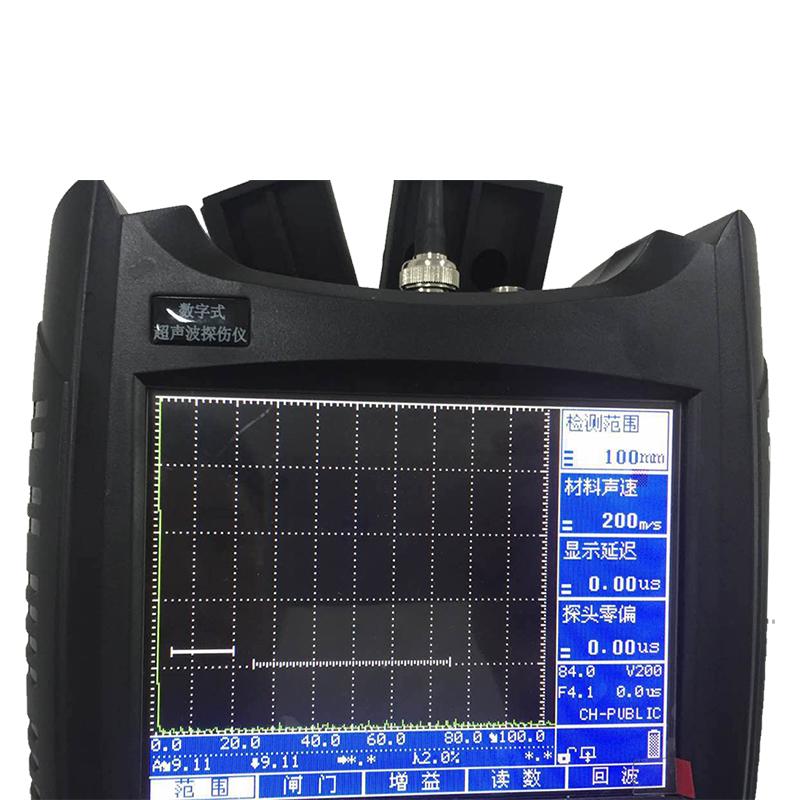

WENTAI HY-350 digital Ultrasonic Flaw Detector

SEWenTai HY-350 Ultrasonic Flaw DetectorSPEC

WenTai HY-350 Ultrasonic Flaw DetectorDetails

WenTai HY-350 Ultrasonic Flaw DetectorPacking list

- SKU

- NB016260

- Gain range

- 110dB

- Bandwidth

- 0.4~20.0MHz

- Detection range

- 0~6000.0mm

- Resolution

- > 40dB

- Dynamic range

- 32dB

- Horizontal linear

- <0.1%

- Vertical Linearity

- <3%

- electrical noise level

- <10%

- Working mode

- Single probe, dual crystal probe, penetration probe

- pulse generator

- Variable pulse generator

- impedance matching

- 50/100/400 Euro automatic matching

- Attenuator Accuracy

- <±1dB/12dB

- digital suppression

- 0~80%, does not affect linearity and gain

- gate

- Inlet gate, loss gate; single gate reading, double gate reading

- Alarm function

- Beep alarm, LED light alarm

- Ambient Temperature

- -10~50℃

- Relative Humidity

- 20~95%RH

Function introduction

1. Full Chinese touch keyboard, intuitive and easy to remember, full Chinese prompts and graphic display during operation, simple training can be mastered.

2. Automatic measurement of instrument and probe performance, automatic instrument calibration, and measurement of thickness and material sound velocity.

3. Ten independent flaw detection channels (electronic switching).

4. A custom flaw detection process can be generated according to actual workpieces (such as welds, forgings, castings, pipes, plates, axles, wheels, small pipe diameters, etc.), and there is no need to carry test blocks for on-site flaw detection.

5. DAC, AVG, decibel DAC curves are automatically generated, the sampling points are not limited, compensation and correction can be performed, the curves automatically float with the gain, and automatically expand with the sound path.

6. Real-time display of defect echo (horizontal, vertical, distance, dB equivalent value), and weld profile display.

7. Incoming wave gate, losing wave gate, DAC sound alarm, door position, door width and door height can be adjusted arbitrarily.

8. With peak memory and envelope functions, it is easier to find the highest waveform.

9. 500 pieces of flaw detection data are stored in the instrument.

10. It adopts a new low-reflection 5.5″EL flat screen (color TFT display), which has strong anti-electromagnetic interference, high contrast and high resolution.

11. Low Voltage sound alarm, automatic shutdown protection.

12. Light weight (only 1.6Kg with battery), small size (dimensions 260X140X55), easy to use and carry.

13. Use imported nickel-metal hydride batteries, automatic protection charging (18VDC, 220VAC), and can work continuously for more than 6 hours.

14. It can work normally in the environment of -20℃~50℃.

- 1The role and application of ultrasonic flaw Detector

- 2Application of Ultrasonic Flaw Detector

- 3Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 4What is an ultrasonic pulse echo system?

- 5Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

- 6What is an ultrasonic flaw Detector?

HY-350

HY-350