PhaseII 900-388 Rockwell Hardness TesterSPEC

PhaseII 900-388 Rockwell Hardness TesterDetails

PhaseII 900-388 Rockwell Hardness TesterPacking list

- SKU

- NB016734

- initial test force

- 29.4N(3kgf), 98.1N (10kgf)

- Total test force

- 147.1N(15kgf), 294.3N(30kgf), 441.3N(45kgf),588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf)

- loading time

- 2~ 50s, can be set/stored

- resolution

- 0.1HR

- Display

- High-precision backlit LCD display

- Measurement space

- 300Mm (vertical), 220mm (horizontal)

- data statistics

- Avg., Max., Min., S, R

- Storage

- 400 sets of measurement data are automatically stored

- Power Supply

- AC, 220V/110V, 50~60Hz, 4A (can be changed)

- Net Weight

- 86 kg (190lbs)

- Power supply Voltage

- AC, 220V/110V, 50~60Hz, 4A (can be changed)

Features

Full closed-loop control, fully automatic loading and measurement, no weight, no installation and debugging, plug and play.

Press the "START" button, which can realize one-key measurement, regardless of the size of the workpiece, the location, and the distance from the indenter, so as to realize the automatic lifting of the workpiece, the active approach to the indenter, the automatic position, and the completion of the whole process of measurement.

It is especially suitable for the testing of industrial batch parts, completely eliminating the human factor and greatly improving the measurement accuracy.

The "convex nose" measurement space can reach 300mm*220mm.

Built-in micro printer.

Product features

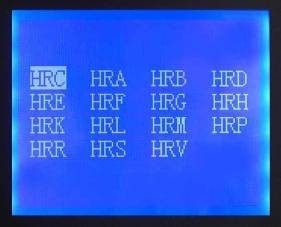

Full Rockwell Function: Includes Rockwell and Surface Rockwell hardness, which measures the hardness of metals and plastics.

The convex nose design can measure the inner surface of the workpiece that cannot be measured by ordinary Rockwell Hardness Testers, such as the inner surface hardness measurement of annular and tubular workpieces.

High measurement accuracy and a wide range of 30 Rockwell hardness values.

It can measure carbon steel, alloy steel, cast iron, non-ferrous metals, etc.

Automatic measurement: workpiece lifting, force loading, load retention, unloading, and value measurement.

The measurement data can be printed directly or exported as an EXCEL sheet by connecting to an external computer via the USB interface.

The measured HR Rockwell values can be converted into HB, HV, HK and σb values.

Complies with Rockwell hardness testing standards: ISO 6508-2, ASTM E18

- 1Measurement Principle of PhaseII PTG Coating Thickness Gauge

- 2How to test the hardness of copper?

- 3When to use Brinell and Rockwell hardness tests?

- 1ASTM -2023《Standard Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers》

- 2JJG 2067-2016《Measuring Instruments for Metallic Rockwell Hardness》

- 3JJG 2092-1995《Measuring Instruments for Plastic Rockwell Hardness》

- 4GB/T 713.7-2023《Steel plate,sheet and strip for pressure equipments—Part 7:Stainless steel and heat resisting steel》

- 5GB/T 713.1-2023《Steel plate,sheet and strip for pressure equipments—Part 1:General requirements》

- 6GB/T 42670-2023《Test method for Rockwell hardness of carbon materials》

900-388

900-388