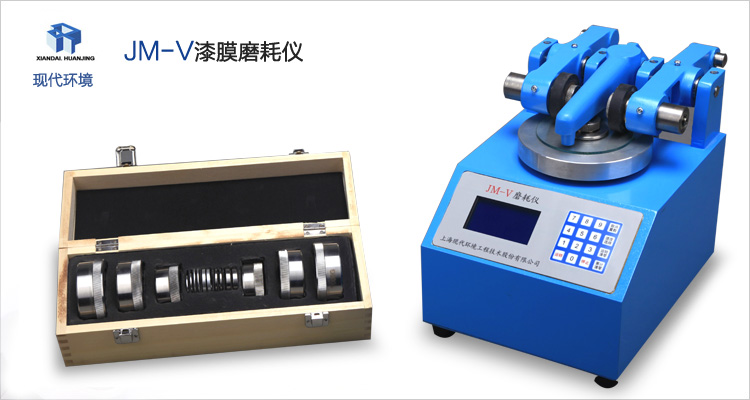

MODERNER JM-V abrasion instrument (wood configuration) load 250g

SEModerner JM-V (wood configuration) Abrasion instrumentSPEC

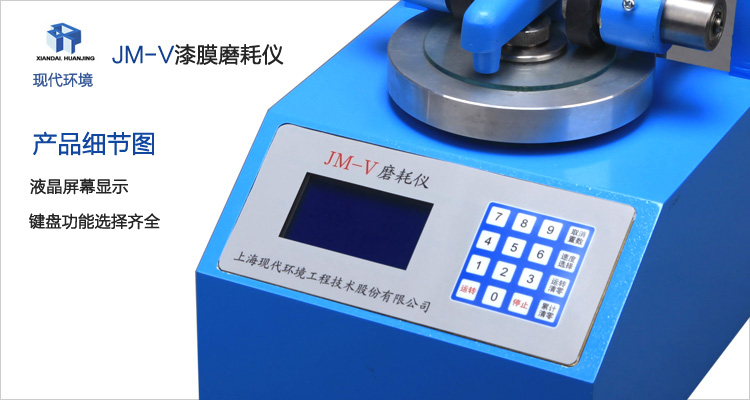

Moderner JM-V (wood configuration) Abrasion instrumentDetails

Moderner JM-V (wood configuration) Abrasion instrumentPacking list

- SKU

- NB021924

- Frictional contact form

- Surface contact friction

- Frictional contact form

- sliding friction

- Grinding head form

- grinding wheel

- Number of grinding heads

- 1

- friction load

- Actual Weight: 250g Indicated Weight: 500g

- Plate speed

- 60/70rpm

- Grinding wheel size

- 51.6x12.7mm

- Counting method

- electron counting

- Machine size

- 220*280*254mm

- Total Weight

- 13kg

- Stepper motor parameters

- 2.5A 21kg-cm

- Grinding wheel equilibrating Weight

- 1/2/5/10/20g (pin 20g)

- Standards

- GB/T1768

Introduction

MODERNER JM-V abrasion Tester (wood configuration) is used to test the wear resistance of wood. It is driven by a stepping motor and programmable. The LCD displays the working parameters and operating status of the wear Tester. JM-V type abrasion Tester refers to the test parameters of wood wear resistance in GB/1757, and provides a multi-purpose test method for wear resistance. JM-V type abrasion Tester is suitable for testing the wear resistance of various coatings in the laboratory, such as deck paint, floor paint, road paint, etc.; it is also suitable for testing the wear resistance of paper, plastic, decorative boards, etc., with simple operation and excellent performance. Reliable, flexible and convenient to use.

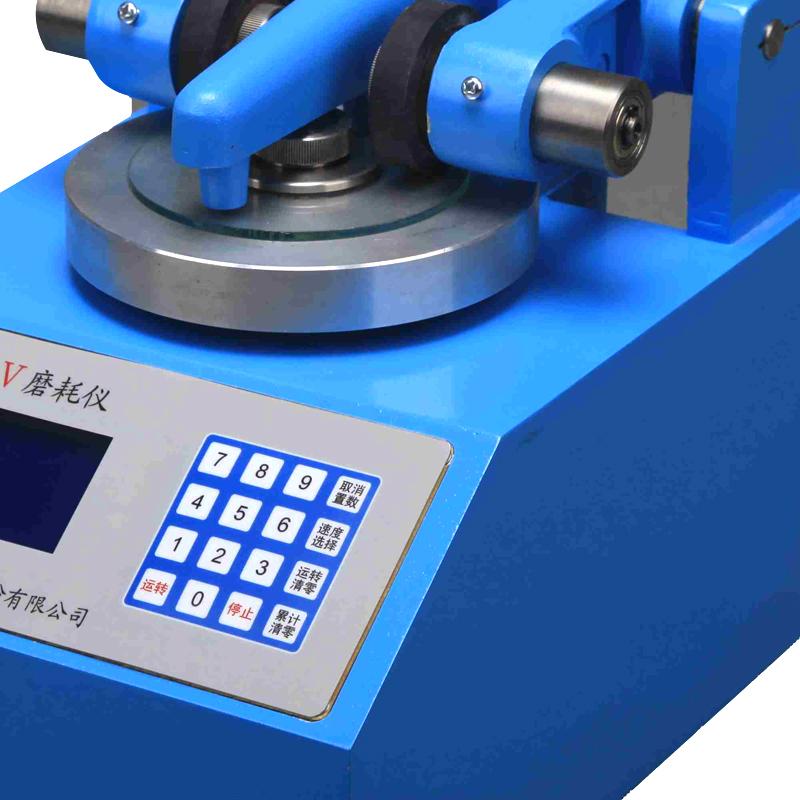

Product principle

The abrasion Tester is to contact two abrasive grinding wheels with a specified distance with the sample sample installed on the horizontal turntable, and make the central axis of the two grinding wheels and the central axis of the turntable not in the same plane. When the turntable rotates, a grinding wheel on the left produces friction from the outside to the center of the sample surface, while a grinding wheel on the right produces friction from the center of the surface of the sample to the outside. When the turntable rotates continuously, a series of intersecting ring friction traces are formed on the surface of the model. With this kind of wear arrangement, the surface of the sample is rubbed in all directions, which avoids obvious directional defects in the friction of the abrasion instrument reciprocating in one direction, and makes the wear evaluation more objective.

The JM-V wear meter is driven by a stepping motor, which avoids the speed change caused by the grid Voltage fluctuation, greatly improves the stability of the work speed of the wear meter, and makes the wear evaluation more comparable.

- 1ASTM D813-2007《Standard Test Method for Rubber Deterioration-Crack Growth》

- 2JC/T 2570-2020《Color sand flooring materials》

- 3 10302-2023《Sag resistance polyurethane waterproofing coating》

- 4 10310-2023《Waterborne polyurethane waterproof coating》

- 5GB/T 4893.8-2023《Test of surface coatings of furniture—Part 8: Determination of resistance to abrasion》

- 6GB/T 39366-2020《Leather colour fastness test, friction colour fastness》

- 7GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 8HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 9HG/T 5183-2017《Water-based ultraviolet curing coatings for woodenware》

- 10ASTM D5264-2019《Standard Practice for Abrasion Resistance of Printed Materials by the Sutherland Rub Tester》

JM-V (wood configuration)

JM-V (wood configuration)