ANGNI AD300L-H (digital display) high-speed dispersion Mulser with 12G/28G dual working head

SEAN AD300L-H (12G/28G) High Speed Dispersion MulserSPEC

AN AD300L-H (12G/28G) High Speed Dispersion MulserDetails

AN AD300L-H (12G/28G) High Speed Dispersion MulserPacking list

- SKU

- NB022919

- Rated Voltage

- AC 220V

- Rated Frequency

- 50/60 Hz

- Input Power

- 510W

- output power

- 300W

- Rated torque

- 13.6 N.cm

- Operating Mode

- S1 (continuous)

- Operation control mode

- Combined control knob

- Speed range

- 2000~18000rpm

- Speed regulation mode

- stepless speed regulation

- Rotation speed display

- LED

- Timer

- 1~1000min

- Approved torque

- 13.5 N.cm

- Work head material

- SS 304 stainless steel

- Adapt work head

- 12G/28G

- Ambient Temperature

- ≤40℃

- Allowable Relative Humidity

- ≤80%

- Dimensions

- 215*310*720mm

- Machine Weight

- 9.7kg

- Processing Capacity

- 30~800mL,90~7000mL

- Max. Processing Viscosity

- 1000cp,6000cp

- Rotor maximum linear velocity

- 11m/s;19m/s

- Maximum immersion liquid height

- 110mm;150mm

- Work head specification

- 12mm;28mm

- Working head length

- 170mm;230mm

- Operating temperature(MAX)

- 120℃

- Work head material

- SS 304

- Bearing material

- PTFE

- Minimum immersion liquid height

- 35mm;50mm

Introduction

The AD300L-H high-speed dispersing and emulsifying machine is driven by a compact series-excited miniature high-speed motor. It is suitable for stirring and mixing low to medium and high viscosity liquids in laboratories or pilot workshops, and for crushing granular materials and shearing in liquid media. emulsification. The machine is composed of high-speed motor, shear emulsification working head and speed controller.

Features

1. The main engine of the drive adopts die-casting aluminum alloy as the body, and the running state is stable;

2. The working head is made of high-quality stainless steel, which has a wide range of experimental applications;

3. The running speed is controlled by the microprocessor, which can immediately and effectively compensate the speed change caused by the load change and the power supply Voltage fluctuation, and the constant speed is reliable;

4. Built-in soft start and automatic overload protection to ensure the safety of long-term full-load continuous operation of the experiment;

5. The stepless adjustment of the speed can meet the need to correct the stirring speed in the experiment at any time;

6. The "H-type" digital display speed is intuitive, which provides convenience for experimental data collection; the operation Timer Control function ensures that the timeliness of the experiment is effective and controllable.

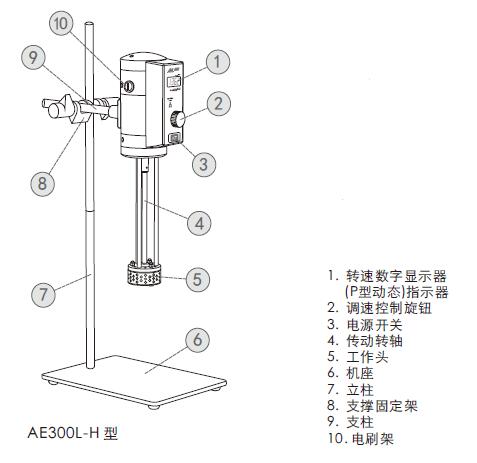

Functional Structure Diagram

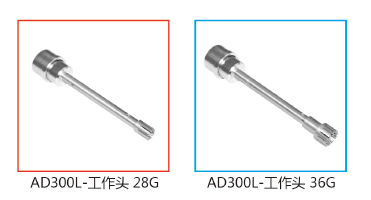

Work head display

Application

AnnieAD300L-H (digital display) high-speed dispersing and emulsifying machine is suitable for tissue dispersion in the field of biotechnology, sample preparation in the medical field, enzyme treatment in the food industry, and liquid and liquid phases in the pharmaceutical industry, cosmetics industry, paint industry and petrochemical industry. Experimental aspects of liquid and solid phases. Under the triple action of extrusion in the feed liquid, strong impact and pressure loss expansion, the experimental medium can be refined and mixed more evenly to prevent or reduce delamination with the feed liquid. Such as: homogenization and emulsification process in the production process of dairy products, beverages, cosmetics, pharmaceuticals and other products.

AD300L-H (12G/28G)

AD300L-H (12G/28G)