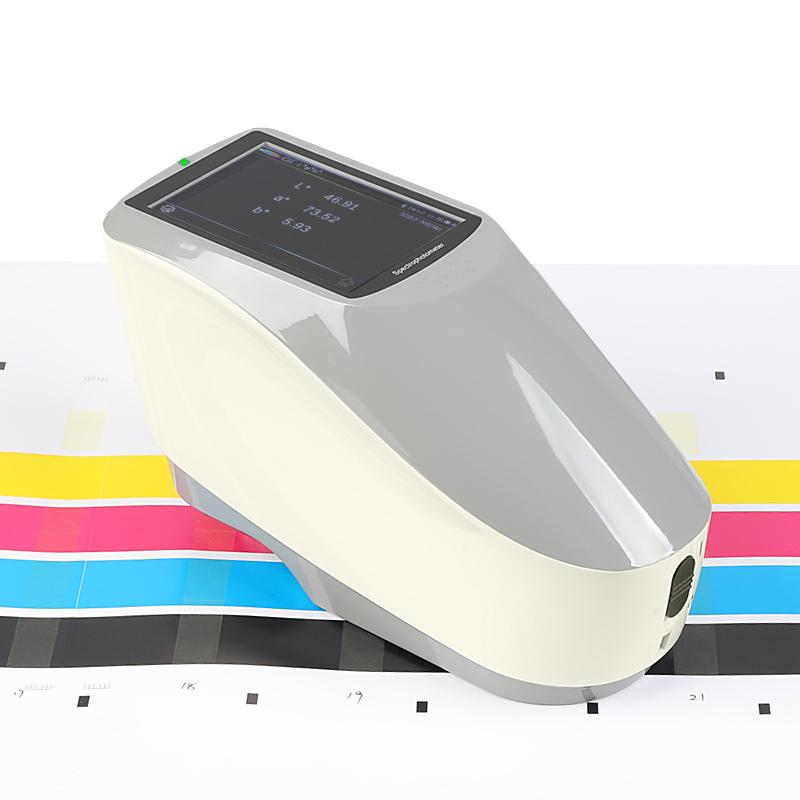

3NH YD5010 Grating Density Spectrometer, Basic Edition

SE3NH YD5010 Grating SpectrophotoMeter SPEC

3NH YD5010 Grating SpectrophotoMeter Details

3NH YD5010 Grating SpectrophotoMeter Packing list

- SKU

- NB023223

- Lighting method

- 45/0 (45 annular uniform illumination 0 ° reception); conforms to standard ISO 5-4, CIE No. 15

- lighting source

- Combination LED light source, UV light source

- Spectroscopic method

- Concave grating spectroscopy

- Sensors

- 256-Pixel dual array CMOS image sensor

- Wavelength range

- 400~700nm

- wavelength spacing

- 10nm

- Light spectrum half bandwidth

- 10nm

- Measurement conditions

- Compliant with ISO 13655 measurement conditions: M0 (CIE light source A) M1 (CIE light source D50) M2 (UV-excluded illumination) M3 (M2 + polarized filter)

- Density standard

- ISO Status T、 E、A、I

- Density index

- Density value, Density difference, Dot area, Dot enlargement, Overprint, Printing characteristics, Printing contrast, Tone error and grayness

- Measurement caliber

- Customized single diameter: Φ2mm, Φ4mm, Φ8mm optional

- Color space

- CIE LAB,XYZ,Yxy,LCh

- Color difference formula

- ΔE * ab, ΔE * 94, ΔE * 00

- Chromaticity indicator

- without

- Viewing Angle

- CIE 2 ° / 10 °

- Observation light source

- A,C,D50,D55,D65,D75,F2,F7,F11,F12

- Measurement time

- About 1.5s

- Density, repeability

- Density value: within 0.01D

- Inter-station difference

- ΔE * from < 0.2

- Measurement mode

- Single measurement, average measurement (2~ 99 times)

- Dimensions

- 184*77*105mm

- Weight

- Approx. 600g

- Battery life

- Lithium battery, 5000 times in 8 hours

- Lighting source life

- 5 years more than 3 million measurements

- Display

- TFT true color 3.5inch, capacitive touch screen

- Data Interface

- USB

- Data storage

- 10000 articles

- Operating language

- Simplified Chinese, English, Traditional Chinese

- Operating conditions

- 0~40 ℃, 0~85% RH (no condensation), altitude: less than 2000m

- Storage environment

- -20~50 ℃, 0~85% RH (no condensation)

YD5010 fully complies with standard ISO 5-4, supports MO, M1, M2, M3 test conditions stipulated in ISO 13655 standard, and can accurately realize ISO Status T, E, A, I density measurement.

YD50 series instruments are stable, accurate in measuring density and chromaticity data, and powerful in function. The instrument is equipped with a variety of measuring calibers. It is widely used in ink printing factories, paper mills, traffic road sign industry, textile and garment printing and dyeing industries, scientific research institutions, quality inspection institutions, and laboratories.

Under the 45/0 geometric optical lighting conditions recommended by CIE, based on the MO, M1, M2, and M3 test conditions specified in the ISO 13655 standard, the instrument can accurately measure the reflectance data of the sample. Various density indicators, color difference formulas, and color indices can be accurately measured and expressed. The instrument is also widely used in the quality control of color difference of various products. The instrument is equipped with high-end color management software, which can be connected to a computer to achieve more functional expansion.

Features

a.45/0 geometric optical structure, conforms to CIE No.15, supports MO, M1, M2, M3 test conditions stipulated in ISO 13655 standard, and accurately realizes ISO T, E, A, I density measurement;

b. Beautiful appearance and structural design in line with human mechanics;

c. Using a combined LED light source with high lifespan and low power consumption, including UV light;

d. Φ2/4/8/20mm caliber can be freely selected to adapt to more samples to be tested;

e. Measure the reflection spectrum of the sample, the CMYK density and Lab data are accurate, which can be used for accurate color transfer;

f. High electronic hardware configuration: 3.5-inch TFT true color screen, capacitive touch screen, concave grating, 256-pixel dual-array CMOS Detector, etc.;

g. USB/Bluetooth 2.1 dual communication mode, wider adaptability;

h. Dirt-resistant and stable standard whiteboard;

i. Large-capacity storage space, which can store more than 20,000 test data

j. Two standard observer angles, multiple light source modes, multiple color systems, chromaticity indicators that meet multiple standards, and meet the needs of various customers for color density measurement;

k. Especially suitable for process control and quality control in printing factories;

l. PC-side software has powerful function extensions;

- 1JJF 1990-2022《Calibration Specification for Standard Integrating Sphere Sources》

- 2GB/T 33568-2017《Evaluation of degradation of coatings on exterior wood》

- 3ISO 2846-1-2017《Graphic technology - Colour and transparency of printing ink sets for four-colour printing - Part 1: Sheet-fed and heat-set web offset lithographic printing》

- 4GB/T 2374-2017《Dyestuffs—General rules for dyeing test》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6QB/T 5160-2017《Test method of artificial leather and synthetic leather一Test method for color measurement》

- 7GB/T 36650-2018《Inks for optical fiber coloring》

- 8HG/T 3951-2007《Water based colorants for architectural coatings》

- 9CY/T 205-2019《Screen printing - Pigment dispersion paste for textile printing process control requirements and test methods》

- 10GB/T 6688-2008《Dyestuffs - Determination of relative strength and color difference - Instrumental method》

YD5010

YD5010