CHNSPEC CRX-51 Non-Contact Colorimeter

SECHNSpec CRX-51 Non-Contact Color SensorsSPEC

CHNSpec CRX-51 Non-Contact Color SensorsDetails

CHNSpec CRX-51 Non-Contact Color SensorsPacking list

- SKU

- NB024765

- Measurement conditions

- D/8 (Light source, 8 degrees Viewing Angle) SCI (including specular reflection component)

- Integrating sphere size

- Should 40mm, Avian-D full diffuse reflection surface coating

- Lighting source

- CLEDs (Full Band Equalized Led Light sources)

- Sensors

- Dual Path Array Sensors

- Measurement distance

- 0.5mm

- Self-calibrating

- Built-in black and white calibrated

- Protection level

- IP67

- Wavelength range

- 400~700nm

- wavelength interval

- 10nm

- Light spectrum Bandwidth

- 5nm

- Measurement range

- 0-200%

- Resolution

- 0.01%

- Measurement caliber

- Φ10mm

- Measurement light source

- A,C,D50,D55,D65,D75,F1,F2,F3,F4,F5,F6,F7,F8,F9,F10,F11,F12,CWF,U30.DLF,NBF,TL83,TL84.U35

- display mode

- Light spectrum chart/data, sample chromatic value, color difference value, pass/fail result, Color bias, display measurement area, historical data color simulation, manual input standard sample, generate test report

- interval time

- 1s

- Measurement time

- Less than 20ms

- Measurement parameters

- CIE-L * a * b, L * C * h, L * u * v, XYZ, Yxy, reflectance

- Color difference formula

- ΔE*ab,ΔE*CH,ΔE*uv,ΔE*cmc(2:1),ΔE*cmc(1:1),ΔE*94,ΔE*00

- Other chroma metrics

- WI(ASTM E313-00,ASTM E313-73,CIE/ISO,

- Repeatability

- Chromatic value: Delta E * ab standard deviation ≤ 0.03, MAX Maximum ≤ 0.05

- Inter-instrument Agreement

- ΔE*ab<0.2

- Operating environment

- 0 ℃ -45 ℃, Relative Humidity 80% or less (at 35 ℃), no condensation

- Storage environment

- -25 ℃ -55 ℃, Relative Humidity 80% or less (at 35 ℃), no condensation

- Interface

- Industrial USB with customizable Miscellaneous interface

- Power supply Voltage

- +12DCV

- Weight

- 1.3kg

- Dimensions

- 100*112*120mm

- Measurement parameter 2

- AATCC, Hunter, Taube Berger Stensby), YI (ASTM D1925, ASTM E313-00, ASTM E313-73), Tint (ASTM E313, CIE, Ganz), Isochromatic Index Milm, viscosity colour fastness, discoloration fastness

Introduction

CRX-51 is a member of the CRX series of non-contact Colorimeters. It adopts the D/8 lighting observation conditions widely used in the world. It is suitable for color matching in various industries and online quality monitoring in coatings, textiles, plastics, food, building materials and other industries.

On-line measurement—on-line color measurement system can continuously obtain product color data, understand sample information more comprehensively and richly, make decisions more quickly, optimize the production and processing process, and ensure product quality. Real-time adjustment of production parameters can save costs and improve production efficiency.

Features

1. The instrument adopts the internationally accepted D/8 (integrating sphere diffuse illumination, 8° observation angle) SCI illumination observation conditions

2. With IP67 dustproof and waterproof grade, it can be applied to harsh Operating Environments.

3. Built-in black and white calibration, automatic black and white calibration can be performed without human intervention.

4. Ultra-high-speed measurement, measurement time 20ms

5. The measurement distance from the sample is 0.5mm, which can realize non-contact online measurement

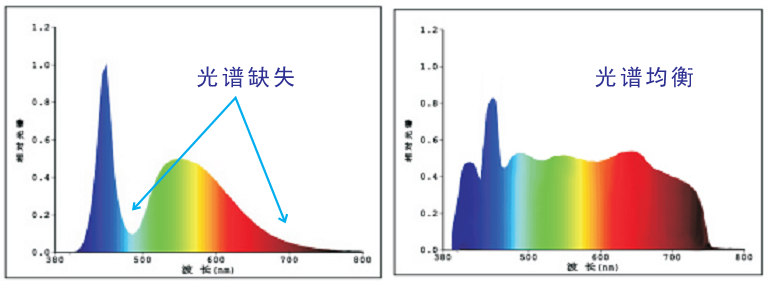

6. Using CLEDs light source - full-band balanced LED light source (patent number: ZL2013107548347)

The full-band balanced LED light source ensures sufficient spectral distribution in the visible light range, avoids the spectrum loss of white LEDs in specific bands, and ensures the measurement speed of the instrument and the accuracy of the measurement results. Journal "Chinese Opics Letters".

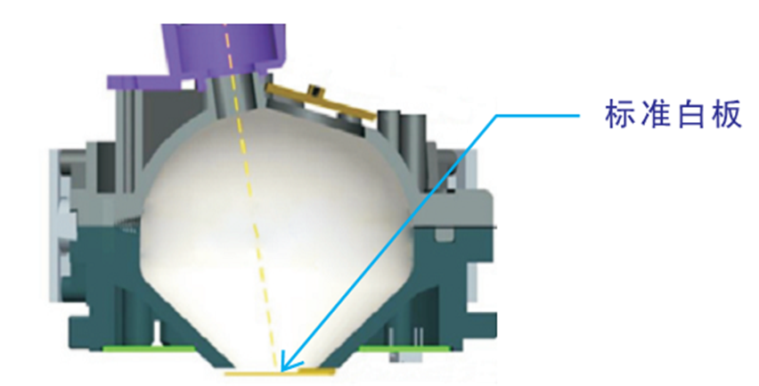

7. ETC real-time calibration technology (patent number: ZL20130373360.1)

The instrument has a built-in standard whiteboard as the measurement benchmark of the instrument. When the whiteboard is stained, the measurement accuracy of the instrument cannot be guaranteed. In the Spectrophotometer products, the innovative ETC real-time calibration technology (Every Test Calibration) is adopted. A standard whiteboard is set inside the optical system, and it has reliable accuracy and repeatability in each test.

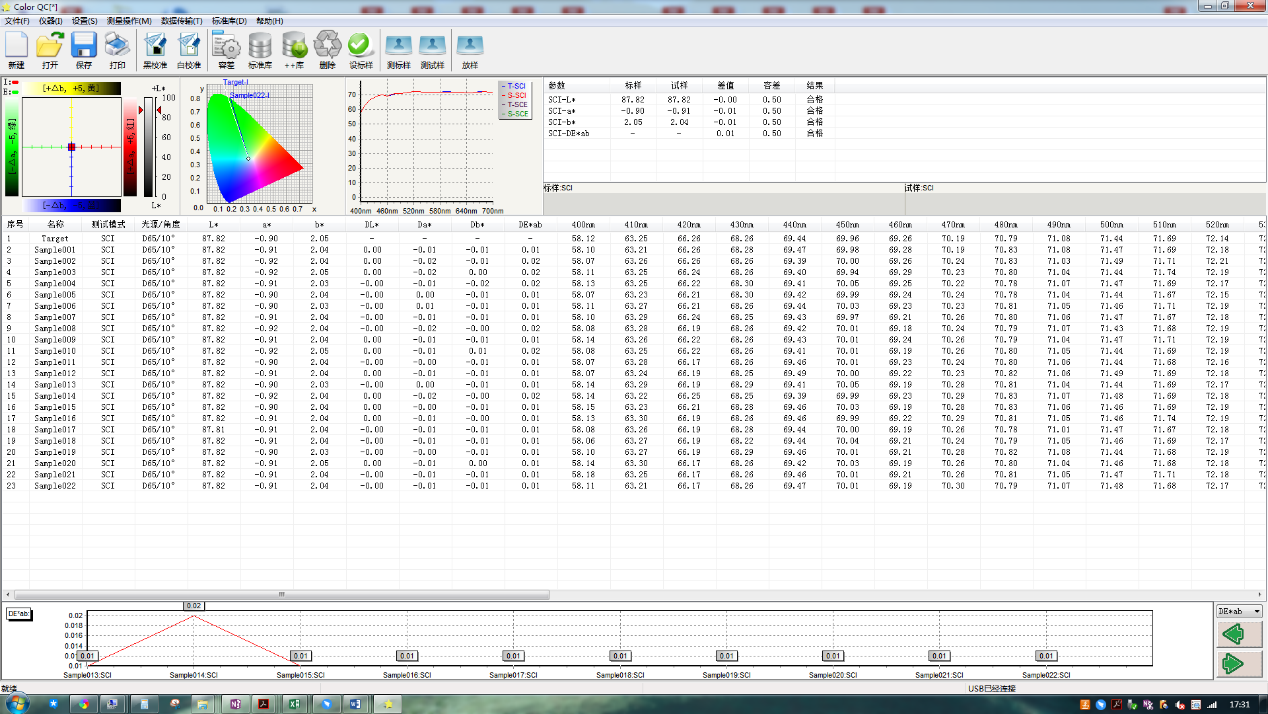

8. Standard color management software

Color management software is provided with the instrument, which is suitable for quality monitoring and color data management in various industries. Dataize the user's color management, compare color differences, generate test reports, provide a variety of color space measurement data, and customize the customer's color management work.

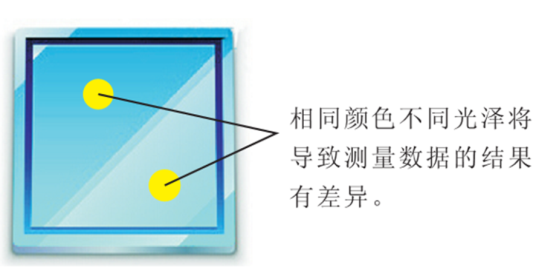

9. Automatic gloss compensation technology (patent number: ZL201310511357.1)

Different gloss on the surface of the material and the lighting observation conditions of the color measuring instrument will have a great impact on the color measurement. Color Spectrum Technology broke the foreign technology blockade and proposed automatic gloss compensation technology earlier in the industry to ensure the accuracy of color measurement data on surfaces with different gloss. The research results were published in the foreign optical SCI journal "OPTIK".

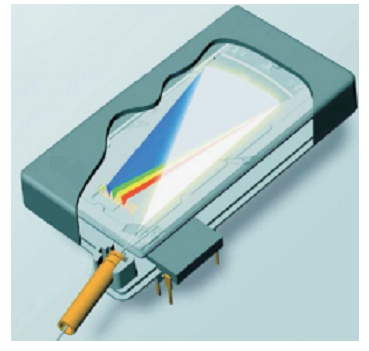

10. Innovative spectroscopic technology SCS optical engine (patent number: ZL201210337619.2)

adopts an innovative single-grating dual-optical path spectroscopic system - SCS optical engine, creating a professional measurement repeatability index in the handheld Spectrophotometer industry, ensuring the accuracy of materials Accurate measurement of surface color.

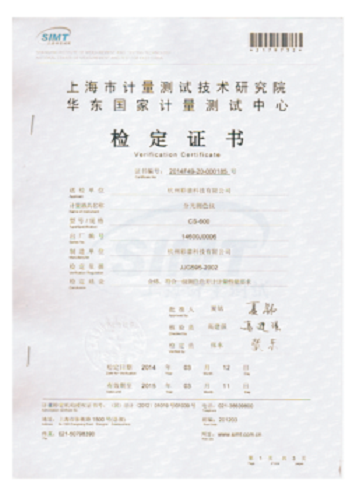

11. Measurement verification report

Each Spectrophotometer has been verified and tested. After leaving the factory, each instrument is verified according to the measurement standards of the credible verification department. The measurement data is traceable to the National Metrology Institute to ensure the reliability of the instrument test data.

plan

- 1GB/T 36392-2025《Coated paper and board for food packaging》

- 2JB/T 5595-1991《Colorimeter》

- 3 0905-2015《Standard test method for color of petroleum products by the automatic tristimulus method》

- 4YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 5GB/T 20147.3-2023《Colorimetry—Part 3:CIE tristimulus values》

- 6GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 7ISO 11664-3-2019《Colorimetry - Part 3: CIE Tristimulus Values》

- 8GB/T 33421-2016《Liquid acid dyes—Determination of shade and relative strength》

- 9GB/T 2374-2017《Dyestuffs—General rules for dyeing test》

- 10GB/T 22374-2018《Floor coating》

CRX-51

CRX-51