Linshang LS220 film instrument, paint Thickness Gauge

SELinShang LS220 Film instrumentSPEC

LinShang LS220 Film instrumentDetails

LinShang LS220 Film instrumentPacking list

- SKU

- NB026416

- Probe

- Ruby fixed

- Measurement principle

- Magnetic induction + eddy current

- Probe Type

- Built-in integrated

- Measuring range

- 0.0 ~ 2000m

- resolution

- 0.1μ m | 1μ m | 0.01mm

- Unit display

- μm / mil

- margin of error

- ±3%

- Measurement interval

- 0.5s

- Minimum measurement surface

- F25mm

- Minimum radius of curvature

- Convex: 5mm/Concave: 25mm

- thinnest matrix

- 0.2mm(F);0.05mm(N)

- Display screen

- 128 × 48 dot matrix LCD

- Power Supply

- 2 1.5V AAA alkalinity batteries

- Operating Temperature

- 0℃-50℃

- Storage temperature

- -20℃-60℃

- Host size

- 101*62*28 mm

- Weight (with battery)

- 79g

Introduction

LS220 is a magnetic and eddy current dual-purpose paint film meter. It is suitable for the measurement of non-magnetic coatings such as paint, varnish, enamel, chromium, and galvanized coatings on ferromagnetic metal substrates such as steel. It can also be used for copper, aluminum, die-cast zinc, yellow Measurement of non-conductive coatings such as paints, anodized layers or ceramics on non-magnetic metal substrates such as copper. It is especially suitable for the thickness detection of automotive paint coatings.

LS220 Paint Film Meter is a coating Measurement Instrument integrated with host and probe, which is very portable. The paint film meter only needs 0.5 seconds to complete a measurement, and does not need to be calibrated, and the operation is very simple.

LS220 paint film meter meets the standards:

DIN EN ISO 2808 Determination of film thickness of paints and varnishes.

JJG-818-2005 Verification Regulations for Magnetic and Eddy Current Overlay Thickness Measuring Instruments.

GB/T 4956-2003 Measurement of thickness of non-magnetic coating on magnetic substrate - Magnetic method.

GB/T 4957-2003 Thickness measurement of non-conductive coating on non-magnetic base metal - eddy current method.

Features

1. The ruby probe is used, which has strong corrosion resistance and wear resistance, ensuring long-term effective use of the instrument.

2. The instrument does not need to be calibrated, it only needs to be zeroed, and the measurement can be started after the zeroing is completed. Single button, easy to operate.

3. It has the function of temperature compensation and digitization of analog signal end to ensure the stability of sensor signal of paint film meter.

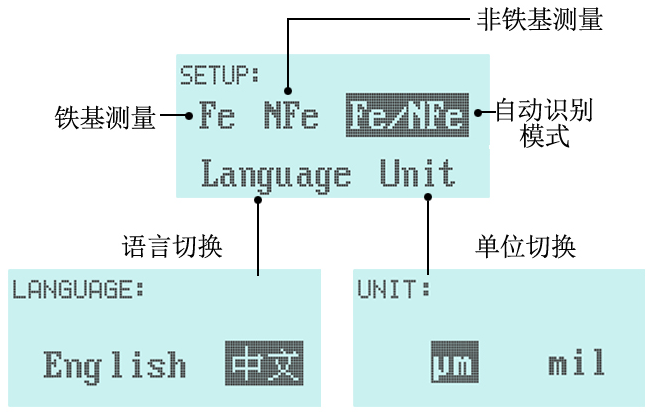

4. It has three measurement modes: iron-based measurement (Fe), non-ferrous-based measurement (NFe) and automatic identification (Fe/NFe).

5. Dual-purpose probes can automatically identify the measurement substrate and can be quickly and automatically switched.

6. It can measure the thickness of the non-magnetic coating layer on the magnetic metal substrate such as iron and steel, and the thickness of the non-conductive coating layer on the non-magnetic metal substrate such as copper and aluminum.

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 5GB/T 1727-2021《General methods for preparation of coating films》

- 6ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 7ISO 2360-2017《Non-conductive coatings on non-magnetic electrically conductive base metals — Measurement of coating thickness — Amplitude-sensitive eddy-current method》

- 8ASTM D7091-2022《Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals》

- 9ASTM E376-2019《Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods》

- 10ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

LS220

LS220