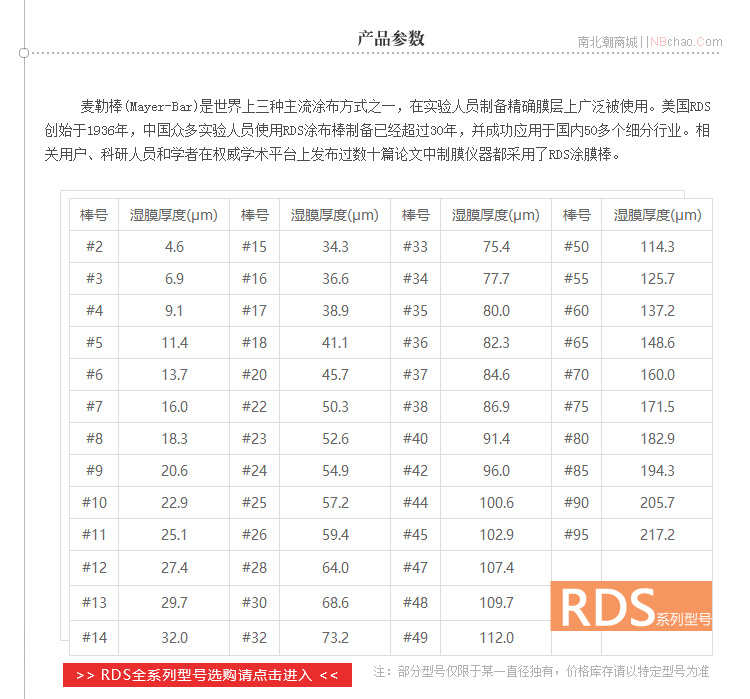

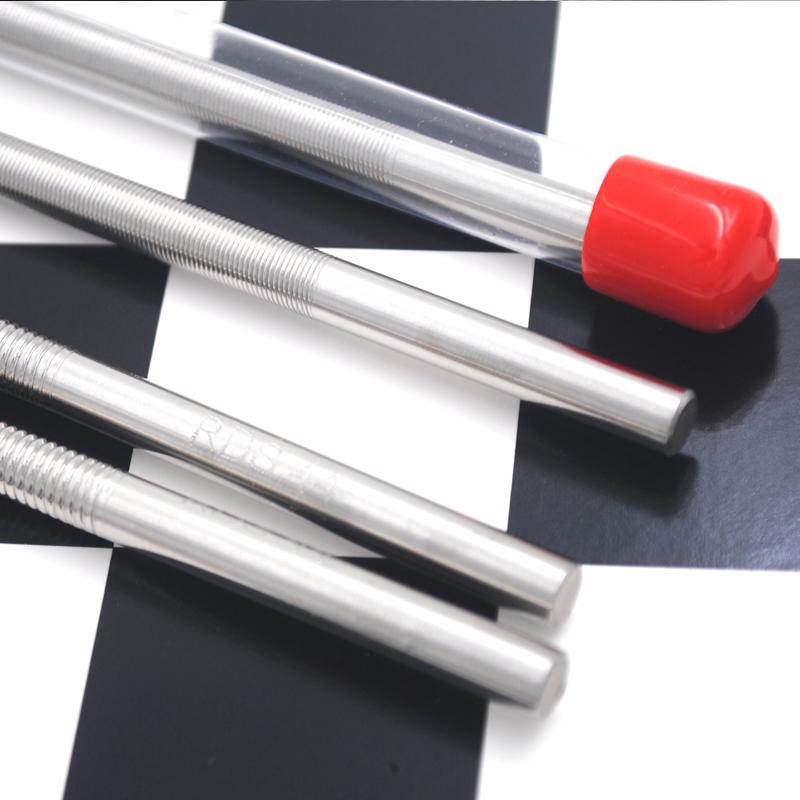

RDS #33 Applicator rod WFT 75.4μm Length 400mm

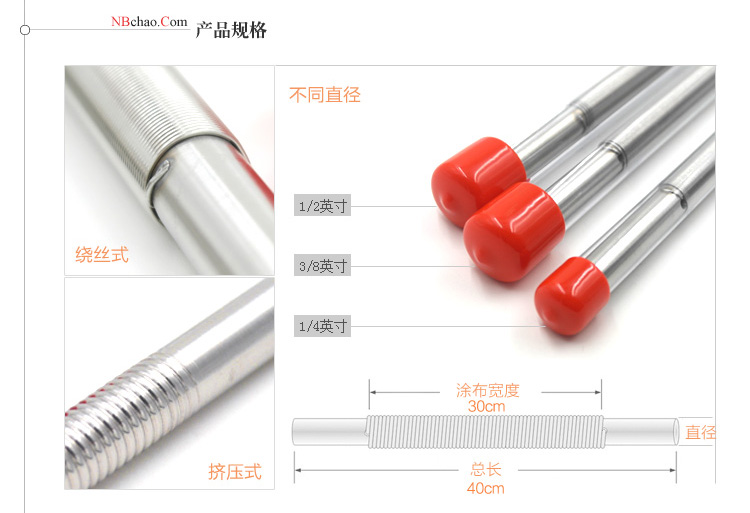

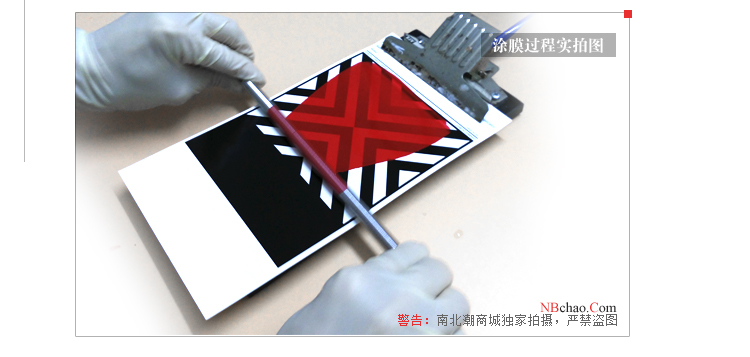

The film thickness of the RDS #33 Applicator rod is 75.4 microns, and the width of the Spreader is 30cm. The No. 33 wire rod is extruded, and it may be clearer and more convenient without broken wire. Produced by the RDS brand, it is of good quality and cost-effective.

Model:

Similar products

RDS 33# 1/4“ Applicator rod 1/4 "SPEC

RDS 33# 1/4“ Applicator rod 1/4 "Details

RDS 33# 1/4“ Applicator rod 1/4 "Packing list

- SKU

- NB000027

- Production process

- formed

- WFT

- 75.4μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

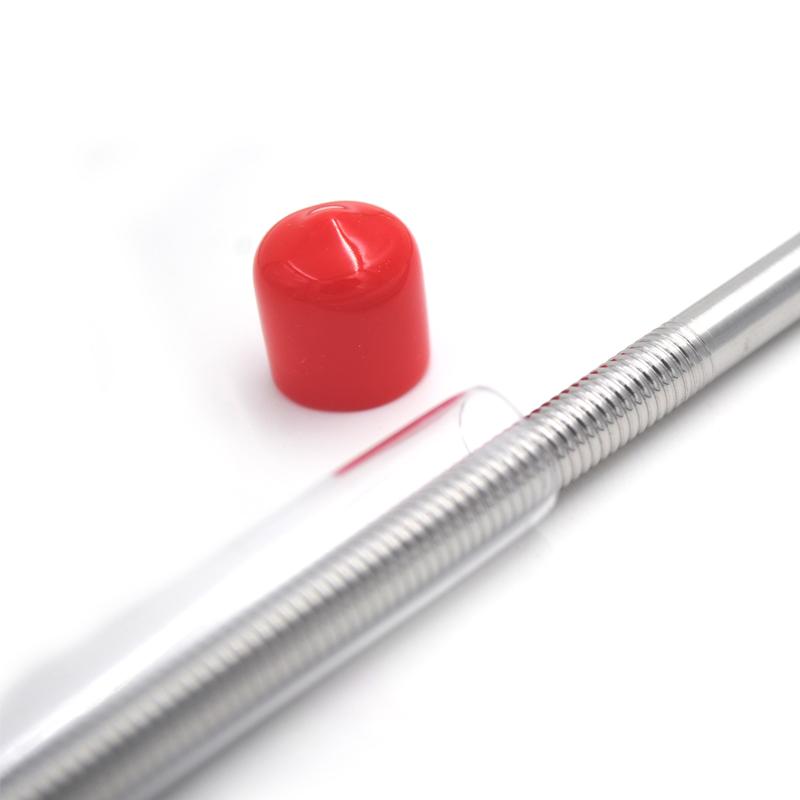

- material

- stainless steel

33# 1/4“

Applicator rod 1/4 "

|  |  |

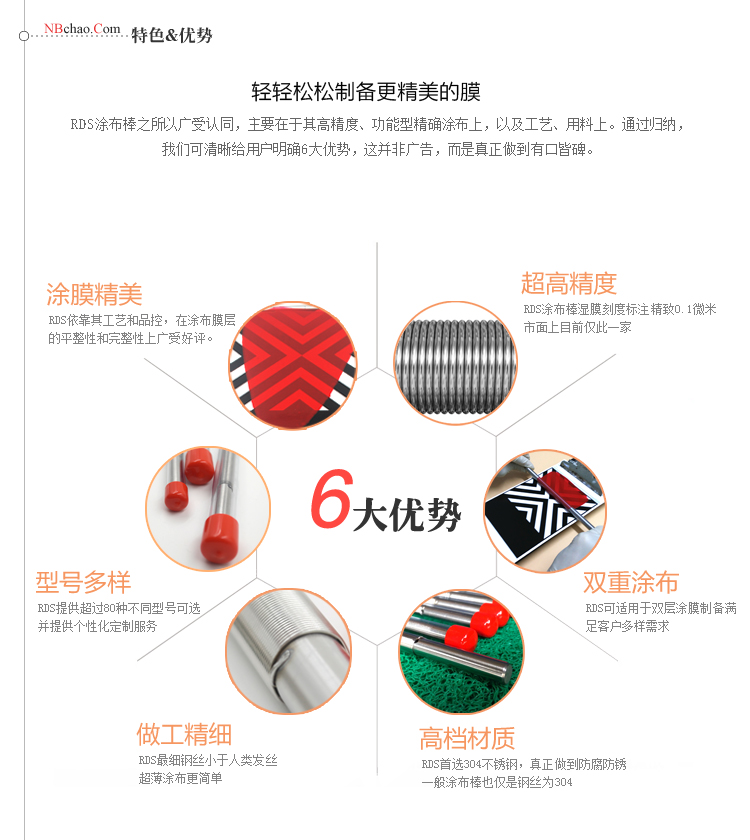

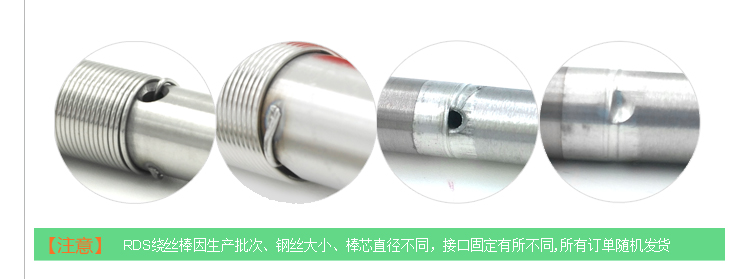

The RDS#33 wire rod applicator has a film thickness of 75.4 microns and a coating width of 30 cm. The RDS wire rod coater is made of 303 stainless steel, and its winding coating rod is not easy to break and rust, has a long service life, and has become a leader in the industry, and has a good reputation. In addition, the forming coating rod is a wire Bar Coater that does not need to be wound with steel wire, which is carefully developed for users to clean after using the coating rod and the problem that the wire winding rod does not pay attention to sometimes blocking impurities, which solves the above two problems well.

Optional

FAQ

QWhat is the difference between the molding rod and the winding process? Is the film thickness different?

A

The winding and molding processes are different, but the film thickness is the same. In the experiment, the effect of both is the same, and the molding is easier to clean. But if it is a Metering rod for production, the amount of Spreader required for the two will be different.

QCoating contains 30% solid content, and it is expected to make Dry-Film 23 microns. Is this suitable?

A

This model is suitable.

33# 1/4“

33# 1/4“