PNSHAR PN-CT50KD Box Compression Tester

PNshar PN-CT50KD FCL compressive testing machineSPEC

PNshar PN-CT50KD FCL compressive testing machineDetails

PNshar PN-CT50KD FCL compressive testing machinePacking list

- SKU

- NB028524

- Power supply Voltage

- AC(100~240)V 5A 50/60Hz

- Error of indication

- ±1%

- Indication variability

- ≤1%

- Force resolution

- 1N

- Force range

- 50~10000N

- Plate size

- 500*500mm

- Working Travel

- 20~500mm

- Pressurization speed

- 10±1mm/min

- return speed

- 5~120mm/min

- monitor

- 4.3 "Color touchscreen

- printout

- modular integrated thermal printer

- Communication interface

- RS232 (std.)/USB (optional)

- Operating Environment

- Indoor temperature (20 +/- 10) ℃; Relative Humidity < 85%

- Weight

- About 166kg

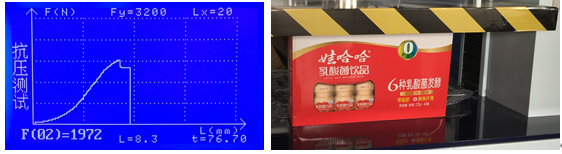

PN-CT50KD FCL compressive testing machine is an economical corrugated carton, honeycomb carton and other packaging compressive and stacking test testing instruments, its performance parameters and technical indicators in line with the provisions of GB/T 4857.3, GB/T 4857.4 and other standards, mainly used for compressive strength test of various small-size corrugated boxes with compressive strength less than 10kN or other materials, such as food and beverage, instant noodle packaging, cosmetics packaging, beer packaging, grain and oil packaging, etc.

The instrument has three independent modes of operation:

1. Strength test:The ultimate compressive strength and deformation of the cabinet are measured. The machine applies an initial load to the specimen as the starting point for deformation, and then continues to apply pressure to the specimen until the specimen is crushed. The maximum pressure and the amount of deformation under pressure of the specimen are automatically recorded.

2. Fixed-value test:The overall performance of the cabinet can be checked according to the set pressure and deformation.

3. Stacking test:Simulate the stacking status of the warehouse, and the stacking test under different conditions can be carried out. When the pressure plate on the testing machine descends to pressurize the specimen to the pre-reached pressure, the timing starts and the deformation of the specimen is calculated. Under the influence of compression deformation of the specimen, the force value decreases continuously, and when the pressure drops to the set value of 2%, the system automatically pressurizes to the test load and holds it until the specified stacking time is reached, and the test is terminated. The test is automatically terminated when the specimen is compressed to the limit deformation.

Execution standards

GB/T 4857.3、GB/T 4857.4、ISO 12048、ISO 2234、QB/T 1048

Features

1. Real-time display of pressure and deformation curves;

2. Pre-set parameters, one-button measurement, simple and effective operation;

3. It has a statistical function, showing the mean value, standard deviation and coefficient of variation;

4. Safety device: overload emergency stop button control, up and down limit control, over-range alarm function.

5. The control circuit part adopts modular design, which is easy to maintain;

6. Open structure design, double lead screw, double guide pillar, good parallelism, good stability, strong rigidity and long service life;

7. Imported stepper motor control and subdivision technology are used to make the instrument accurate positioning and fast speed response, which saves test time and improves test efficiency;

8. Using high-speed ARM processor and 24-bit high-precision AD converter, the data processing speed is fast and the accuracy is high;

9. Built-in thermal printer, convenient to print test report;

10. It can be connected to computer software, and the test data can be exported to EXCEL, which is convenient for data saving, analysis and management.

PN-CT50KD

PN-CT50KD