RDS 5 #3/8 "+ KHC.21 Applicator rod + Drawdown Plate set

SE-

RDS 5 #3/8 "Mayer Rods WFT 11.4μm inks Color Colorimetric$ 162.00SE

RDS 5 #3/8 "Mayer Rods WFT 11.4μm inks Color Colorimetric$ 162.00SE -

RDS 5 #1/4 "wire-wound Applicator rod film thickness 11.4μm Wire diameter 0.13mm$ 156.00SE

RDS 5 #1/4 "wire-wound Applicator rod film thickness 11.4μm Wire diameter 0.13mm$ 156.00SE -

RDS 5 #1/2 "Steel Wire Drawdown Rod film thickness 11.4μm Wire diameter 0.13mm$ 181.00SE

RDS 5 #1/2 "Steel Wire Drawdown Rod film thickness 11.4μm Wire diameter 0.13mm$ 181.00SE -

RDS 5 #1/4 "grooved rod film thickness 11.4μm rod diameter 6.35mm$ 156.00SE

RDS 5 #1/4 "grooved rod film thickness 11.4μm rod diameter 6.35mm$ 156.00SE

RDS 5# 3/8"+KHC.21 Applicator rod setSPEC

RDS 5# 3/8"+KHC.21 Applicator rod setDetails

RDS 5# 3/8"+KHC.21 Applicator rod setPacking list

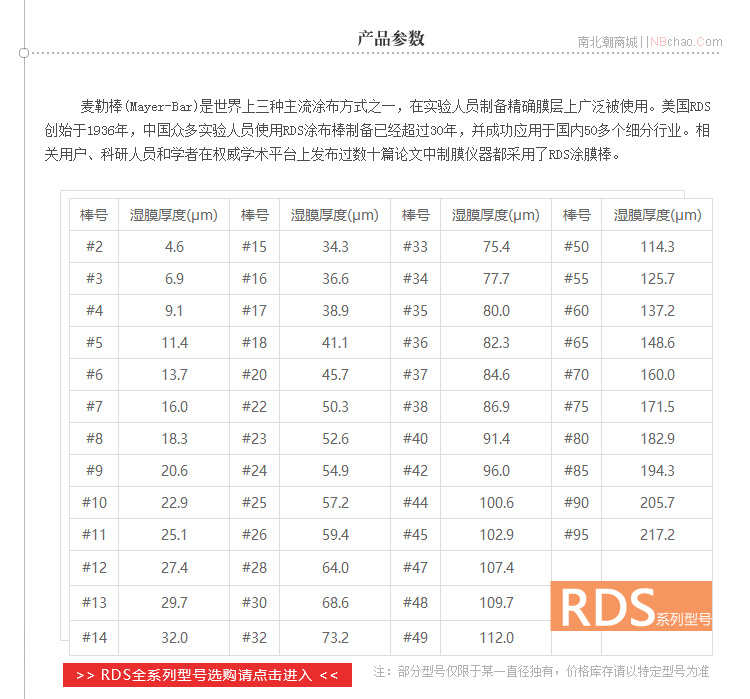

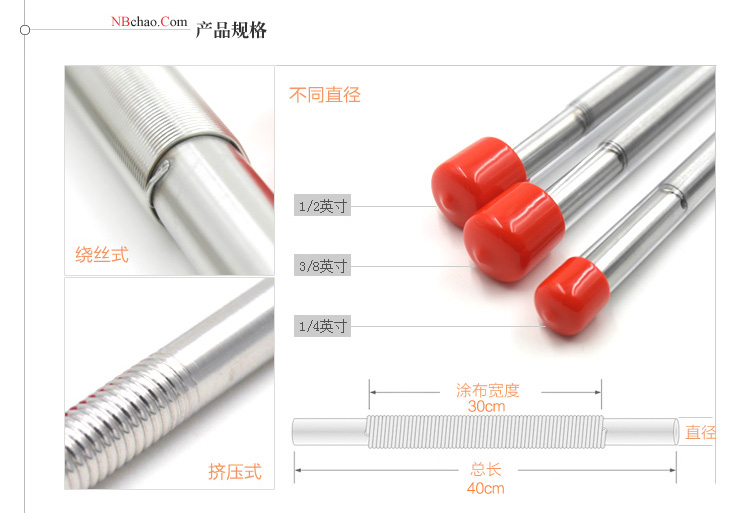

- SKU

- NB028956

- Production process

- wire-wound

- WFT

- 11.4μm

- diameter

- 9.5mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.13mm

- Drawdown Plate Model

- KHC.21

- Coating table size

- 24*34cm

- Baseplate size

- 430*247*12mm

- material

- rigid polyester board + foam layer + rubber cushion

- Net Weight

- 2.08kg

|  |  |

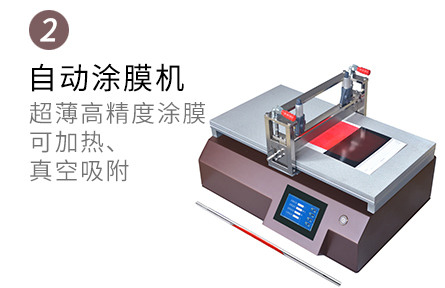

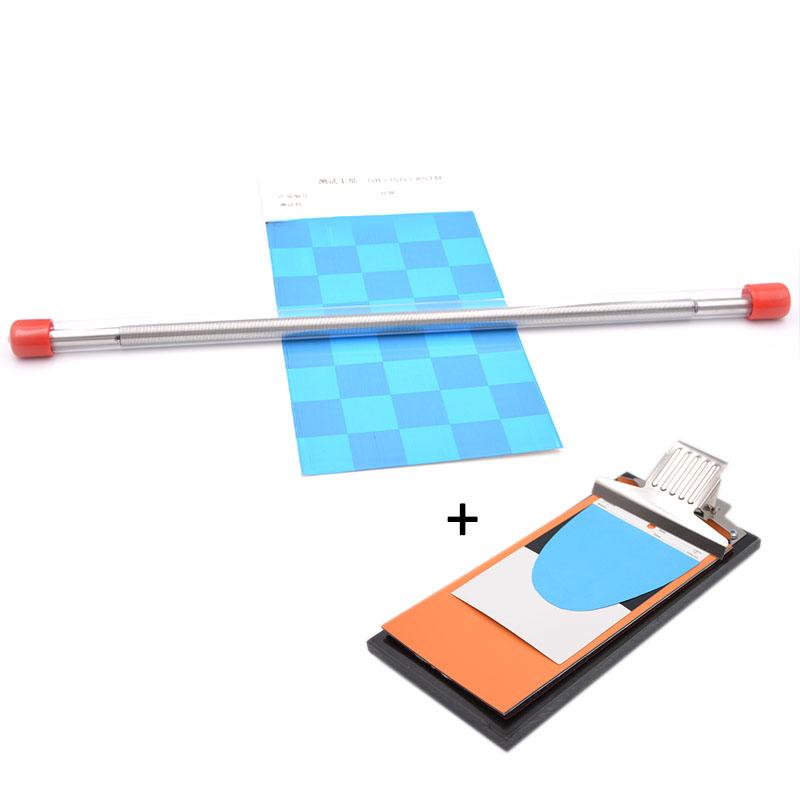

The RDS 5# 3/8"+KHC.21 Doctor Wand + Stamping Table Set consists of an RDS5 wire rod and an embossing table.

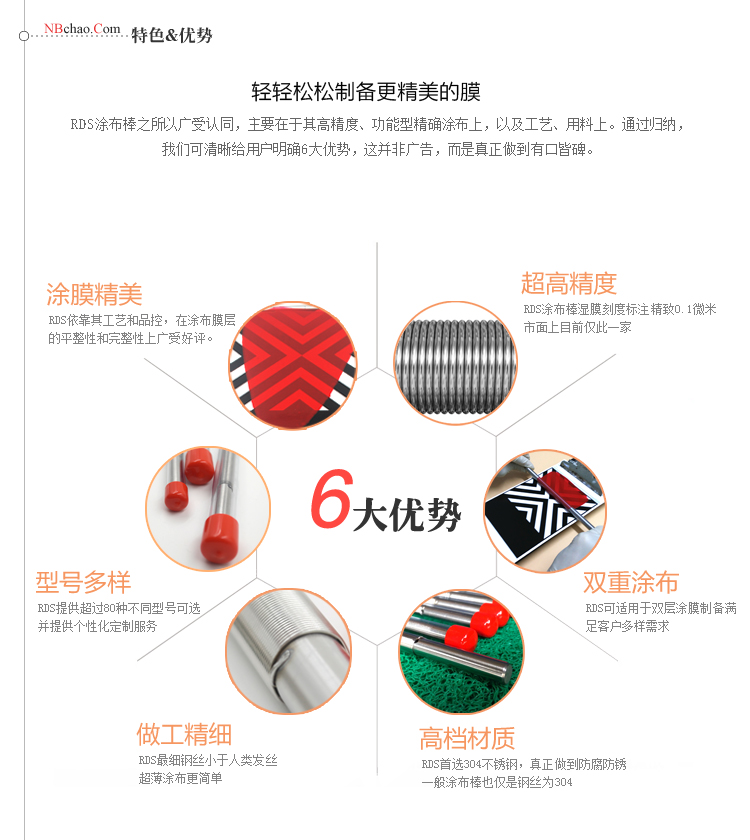

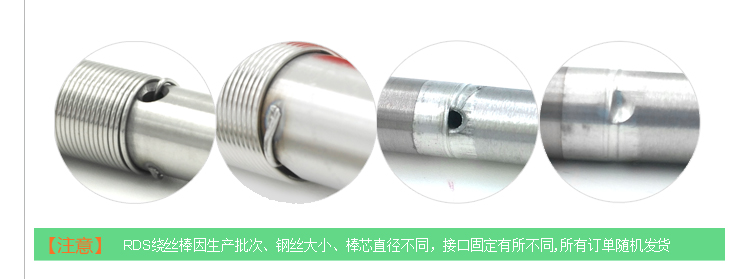

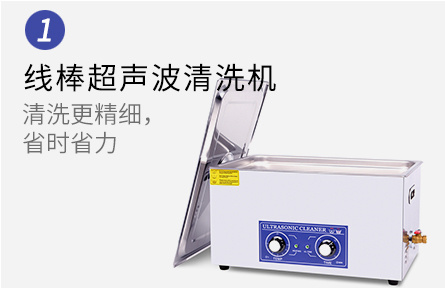

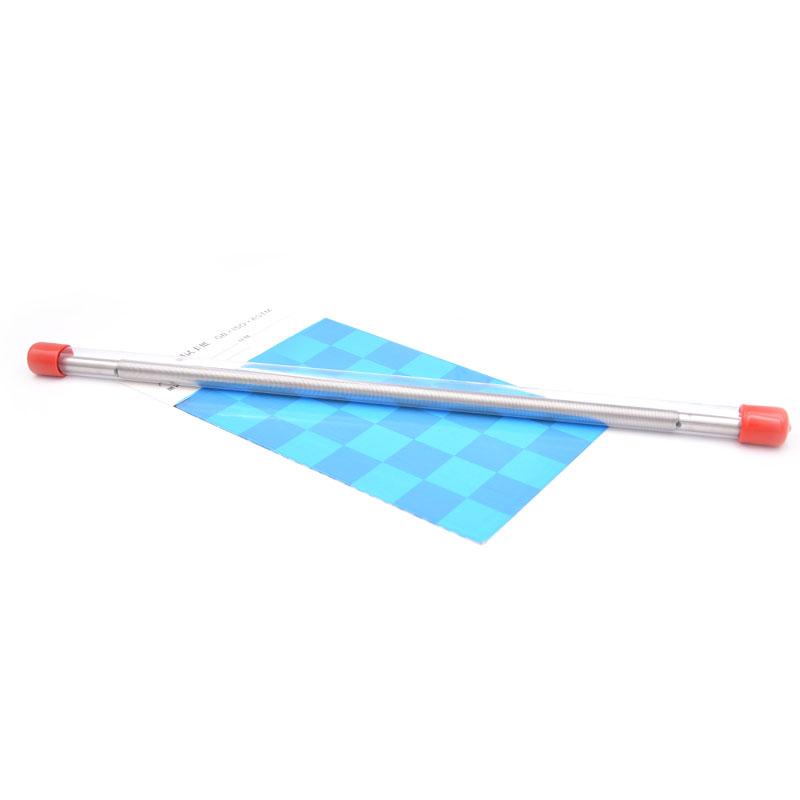

The RDS 5 wire bar applicator (also known as the coating rod and squeegee bar) can be used for laboratory preparation of precise film layers, the No. 5 squeegee bar is made of high-grade stainless steel, depending on the process, RDS provides No. 5 forming coating rod, No. 5 filament wound coating rod, and the filament wound wire bar applicator can also be selected in 1/4, 3/8 and 1/2 inch diameters. Theoretically, the wet film thickness of wet film coatings prepared with different diameters is the same, but the difference is that the amount of coating used will be different due to the different groove shape and main rod diameter. The mainstream in CHINA is 3/8 diameter, while in Taiwan, CHINA and Singapore, more 1/4 diameter wire bar applicators are used.

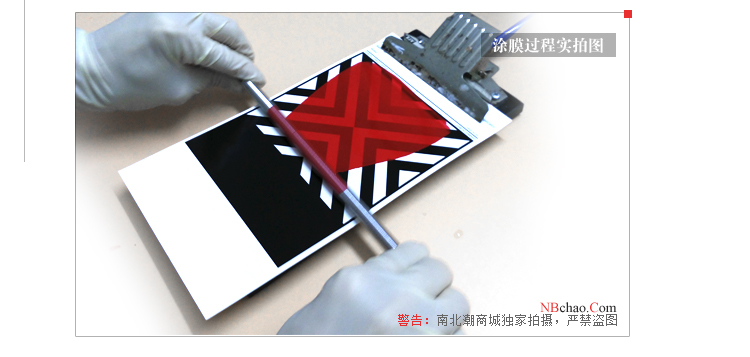

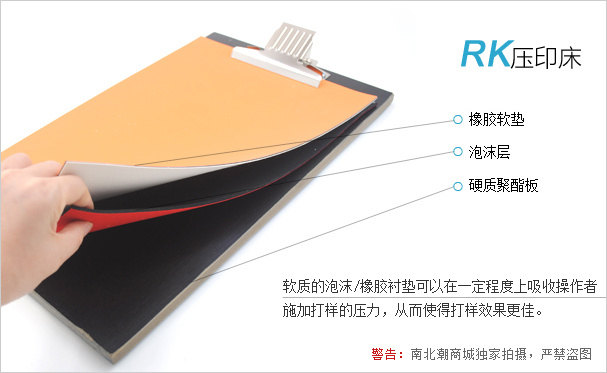

RKThe embossing table consists of a clip, a rigid polyester sheet, and a layer of foam/rubber upholstery. Compared to proofing directly on a hard substrate, proofing on an RK imprint machine has better repeatability and proofing results. This is due to the fact that the soft foam/rubber liner can absorb the pressure applied by the operator to a certain extent, so as to make the proofing effect better.

Illustration of the RK imprint bed

Optional

| |

|  |

Note: Click on the accessory image to view the product details.

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

- 8ISO 1513-2010《Coatings and varnishes. Test specimen inspection and prepatives》

5# 3/8"+KHC.21

5# 3/8"+KHC.21