PORUIKE VUT-800A high-precision Ultrasonic Flaw Detector

PoRuiKe VUT-800A Ultrasonic Flaw DetectorSPEC

PoRuiKe VUT-800A Ultrasonic Flaw DetectorDetails

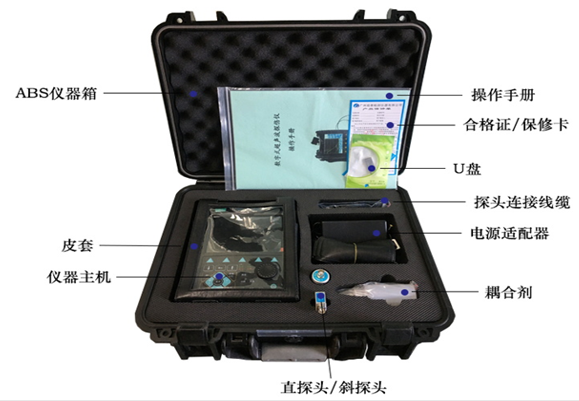

PoRuiKe VUT-800A Ultrasonic Flaw DetectorPacking list

- SKU

- NB029794

- Scanning range

- 0~9999mm

- Speed of sound

- 1000~15000m/s

- number of storage channels

- 500

- Number of stored waveforms

- 5000

- video recording

- 5min×10

- Gain Range

- 0dB~100dB

- display delay

- -15μs~+3400μs

- Probe zero

- 0μs~1000μs

- Frequency range

- 0.2~15MHz

- impedance matching

- 50/75/150/500Ω

- electrical noise level

- ≤10%

- Frequency of sexual repeability

- Automatic low, automatic medium, automatic high, 5~ 1000Hz

- Sensitivity margin

- ≥ 62dB

- Dynamic range

- ≥ 40dB

- Horizontal Linearity

- ≤ 0.1%

- Vertical Linearity

- ≤ 3%

- Far field resolution

- ≥ 32dB

- pulse intensity

- fixed

- pulse width

- 50~1000ns

- Storage Capacity

- 1GB

- Environmental temperature

- -10~50℃

- Operating Time

- ≥20H

- Operating language

- Simplified Chinese/English

- Communication interface

- High-speed USB interface

- size

- 263*170*61mm

- Power Supply

- Direct current (DC) 9V; lithium battery works continuously for more than 6 to 8 hours

- Power Supply

- 220V,50Hz,8.4V

- Machine Weight

- About 1.3Kg (including battery)

VUT800A is a true color display all-digital ultrasonic flaw Detector, which can quickly and conveniently, without damage, and accurately detect, locate, evaluate and diagnose a variety of defects (cracks, inclusions, porosity, etc.) inside the workpiece. It is used both in the laboratory and in the field of engineering. This instrument is widely used in special inspection institutes, construction engineering quality inspection stations, boiler and pressure vessel manufacturing, construction machinery manufacturing, iron and steel metallurgy, steel structure manufacturing, shipbuilding, oil and gas equipment manufacturing and other fields that require defect detection and quality control, and is also widely used in aerospace, railway transportation, boiler and pressure vessel and other fields of in-service safety inspection and life assessment.

Features

Full Chinese operation key film, simple and easy to understand.

Full Chinese display, master-slave menu, and designed with shortcut buttons and digital shuttle wheel, easy to operate, technical professional.

The all-digital true color liquid crystal display (TFT) can select the background color and waveform color according to the environment, and the LCD brightness can be set freely.

The high-performance security battery module is easy to disassemble and assemble, can be charged offline independently, and the large-capacity high-performance lithium-ion battery module extends the continuous working time of the instrument to more than eight hours;

The instrument is light and portable, can be held with one hand, is durable, and leads the industry trend.

Amplify the reception

Hardware real-time sampling: 10-bit AD converter, sampling speed 160MHz, hardware real-time sampling, waveform high fidelity

Detection mode: positive half-wave, negative half-wave, full-wave, RF detection

The filter frequency band (0.25~20) MHz is automatically matched according to the probe frequency, and no manual setting is required.

Gate reading: single gate and double gate reading methods are optional; Peak readings within the gate

Gain: The total gain is 110dB, with 0, 0.1dB, 1dB, 2dB, 6dB step values, and the unique automatic increase

Benefit adjustment and scan gain function make flaw detection fast and accurate.

Flaw detection function

Peak memory: real-time retrieval of the highest defect wave, record the maximum defect value

Φ value calculation: the flaw detection of straight probe forgings automatically calculates and displays the equivalent size of the defect after finding the highest wave of the defect

Defect location: Real-time display of defect level, depth (vertical), and sound path position

Defect sizing: The defect equivalent dB value is displayed in real time

Defect qualitative: through the echo envelope waveform, it is convenient for manual experience judgment

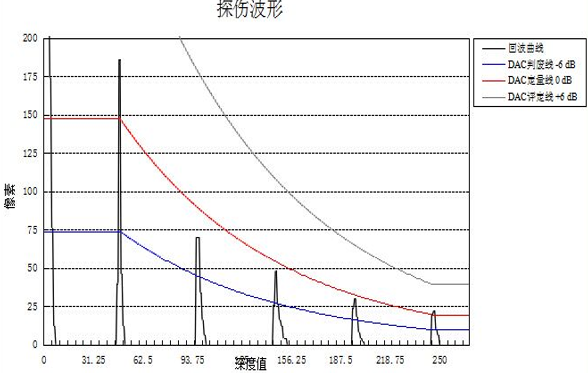

DAC/AVG: Curves are automatically generated, sampling points are not limited, and compensation and correction can be made. The curve automatically floats with gain, expands with the sound path, and moves with the delay. AVG curves can be displayed for any aperture.

National standard legend

Emission pulse

Pulse amplitude: low (300 volts), medium (500 volts), high (700 volts) graded selection, suitable for a wide range of probes

Pulse width: Continuously adjusted in the range of (0.1~0.5)μs to match probes of different frequencies

Probe damping: 100Ω, 200Ω, 400Ω optional, to meet the different requirements of sensitivity and resolution

Working mode: straight probe, oblique probe, dual element transducer, penetrating flaw detection

Detection range

Zero interface incidence 0~9999mm (steel medium and longitudinal waves), which can be continuously adjusted

Gate alarm

Door position, door width and door height can be adjusted arbitrarily; B. The gate can be optionally set with incoming wave alarm or lost wave alarm; Alarm and shutdown of beeps and LED lights (LED lights are very effective in noisy environments) in the gate.

Data storage

500 sets of flaw detection parameter channels, the combined parameters of various probes and instruments can be adjusted in advance, and the flaw detection standards of various industries can be set freely; It can store 1000 flaw detection echo signals and parameters, which can be stored, read out and transmitted through USB interface.

Real-time clock

Real-time flaw detection date and time tracking record, and record storage.

Communication interface

USB2.0 high-speed communication transmission interface

Battery module

High-capacity lithium battery module, online charging and offline charging, convenient for flaw detection personnel

Standard configuration

- 1What is an ultrasonic pulse echo system?

- 2Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 3The working principle and application of eddy current Flaw Detector

- 4Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

- 5Application of Ultrasonic Flaw Detector

VUT-800A

VUT-800A