RDS 26 #3/8"Double wire-wound Applicator rod 59.4μm wet film thickness Wear resistant stainless steel

-

RDS 26 #3/8 "Applicator rod WFT 59.4μm Length 400mm$ 162.00SE

RDS 26 #3/8 "Applicator rod WFT 59.4μm Length 400mm$ 162.00SE -

RDS 26 #1/2 "Steel Wire Drawdown Rod film thickness 54.9μm Wire diameter 0.66mm$ 181.00SE

RDS 26 #1/2 "Steel Wire Drawdown Rod film thickness 54.9μm Wire diameter 0.66mm$ 181.00SE -

RDS 26 #1/4 "printing roll Wire-wound drawdown Bar film thickness 59.4μm rod diameter 6.35mm$ 156.00SE

RDS 26 #1/4 "printing roll Wire-wound drawdown Bar film thickness 59.4μm rod diameter 6.35mm$ 156.00SE -

RDS 26 #1/4 "wire-wound Applicator rod film thickness 59.4μm Wire diameter 0.66mm$ 156.00SE

RDS 26 #1/4 "wire-wound Applicator rod film thickness 59.4μm Wire diameter 0.66mm$ 156.00SE

RDS 26# 3/8" Double wide-wound Applicator rodSPEC

RDS 26# 3/8" Double wide-wound Applicator rodDetails

RDS 26# 3/8" Double wide-wound Applicator rodPacking list

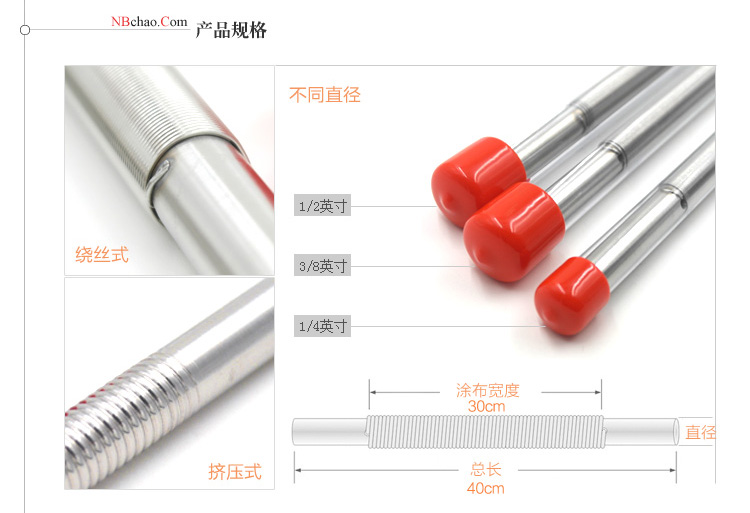

- SKU

- NB030168

- Production process

- Double wire-wound

- WFT

- 59.4μm

- diameter

- 9.52mm

- Total length

- 400mm

- Spreader Width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.66mm

|  |  |

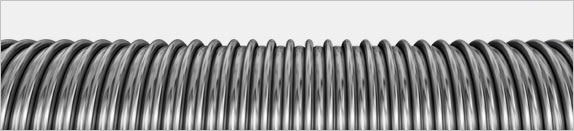

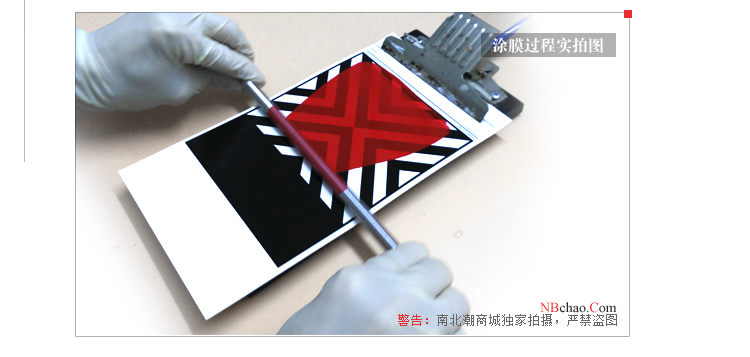

RDS26# double-wound filament scraper rod prepares wet film with a thickness of 59.4 microns, a rod diameter of 9.5mm, wear-resistant stainless steel, an effective coating width of 300mm, and a steel Wire diameter of 0.66mm.

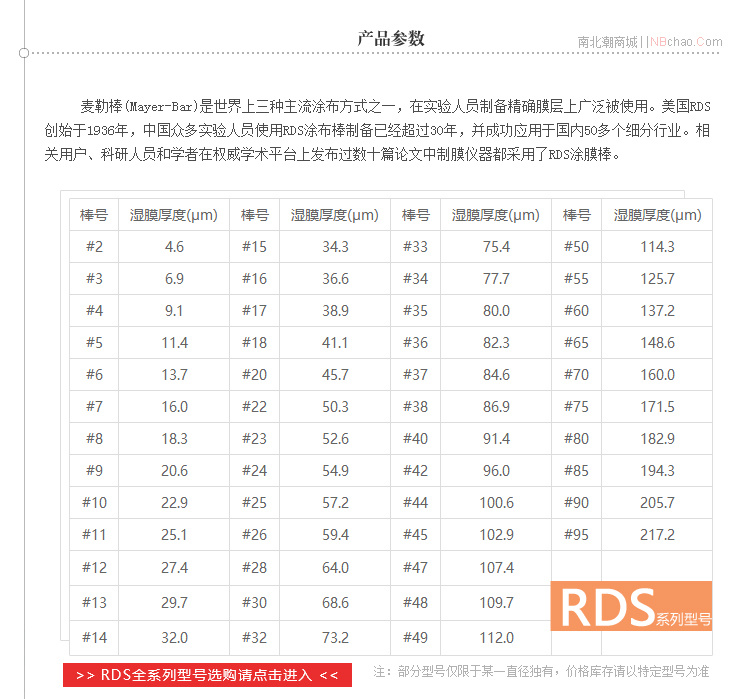

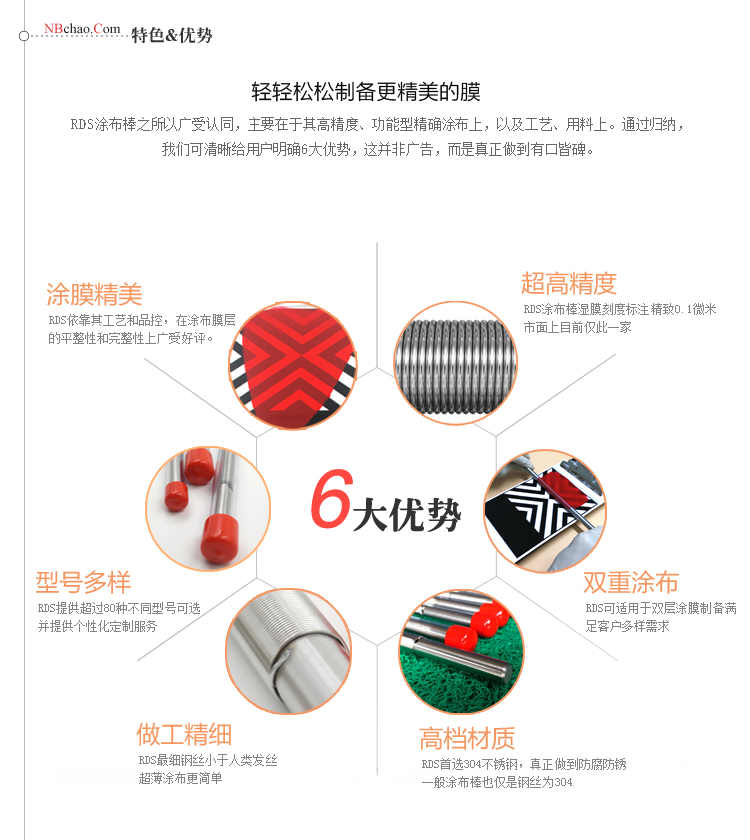

United StatesRDS is a more than 80 years of technical experience in the development and production of coated rods, RDS wire rod coaters are favored by many users in CHINA, with good materials, up to 0.1 micron coating film accuracy advantages to become a well-known brand of coating rods in the industry.

RDS provides a variety of experimental wire rods with different process specifications to meet the needs of experimental coating films in a variety of industries. Cords are availableWound, formed (grooved), double-wound and open bar up to 12 feet in length. 3 different diameters of stainless steel rods, more than 70 sizes of stainless steel wires. Customization is accepted.

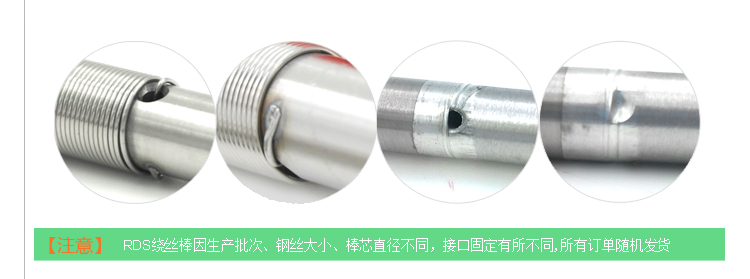

Double-wound wire rods reduce clogging and eliminate stitches for higher viscosity coatings. The grooves created by wrapping smaller lines around a larger tip (see picture) are wide and shallow, allowing heavy paint to flow better. The smaller tip line creates a smaller break in the paint flow so that the paint can be saturated more completely. Although double spooled wire bars are more expensive than open wire bars, they are also more durable.

26# 3/8"

26# 3/8"