RD-Coater-S300 Desktop Multifunctional Applicator, Scraper/Wire Stick/Slit Applicator

NanoUp RD-Coater-S300 Desktop Spreader System HostSPEC

NanoUp RD-Coater-S300 Desktop Spreader System HostDetails

NanoUp RD-Coater-S300 Desktop Spreader System HostPacking list

- SKU

- NB032348

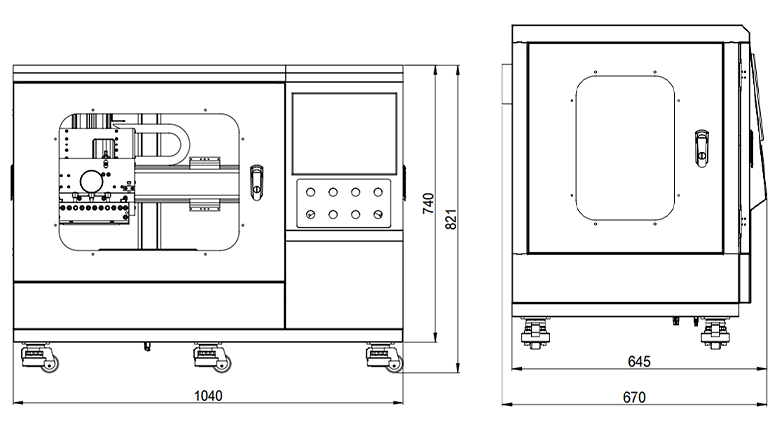

- Dimensions

- 619*606*680 mm

- Workbench range

- X:300 Y:300 Z:100 mm(选配)

- Platform plane Accuracy

- ±5μm (100 mm)

- Clearance control Accuracy

- 2 μm

- Speed range

- 0-60 (X axis) 0-70 (Y axis) 0-40 (Z axis) mm/s

- Substrate heating temperature

- 0-180 ℃

- Temperature deviation

- ±2 ℃

- Ink supply flow

- 0.001-1 ml/s

- Solvent system

- Waterborne, oily, organic solvent based coatings

- Applicable substrates

- Glass, PET, CPI, aluminum foil and other flexible substrates

- Substrate clamping method

- Vacuum adsorption

- Key control method

- Touch screen control

- Application process

- Slit Application, ultrasonic lame plating, scraper scraping, bar roller painting (optional)

- Application Film thickness range

- 0.05-20 μm (thickness of dry film) depending on Application process and Printing ink

- Application width

- 10-200 mm depending on the choice of Application head

- Application number

- 1-10 The number of Applications can be freely set

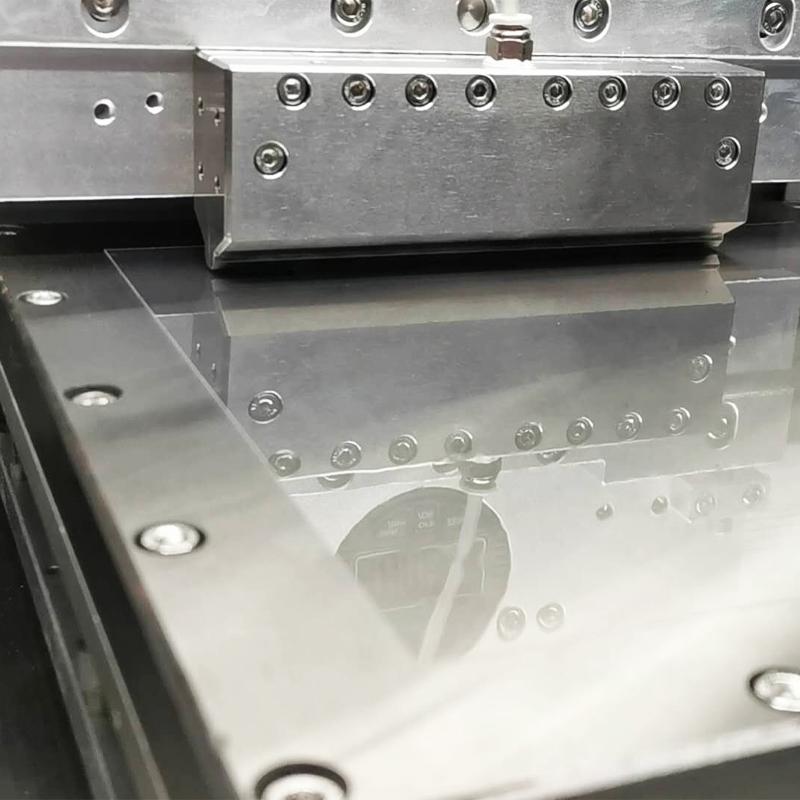

- Slit head inner surface linearity

- ≤ 1.5 μm

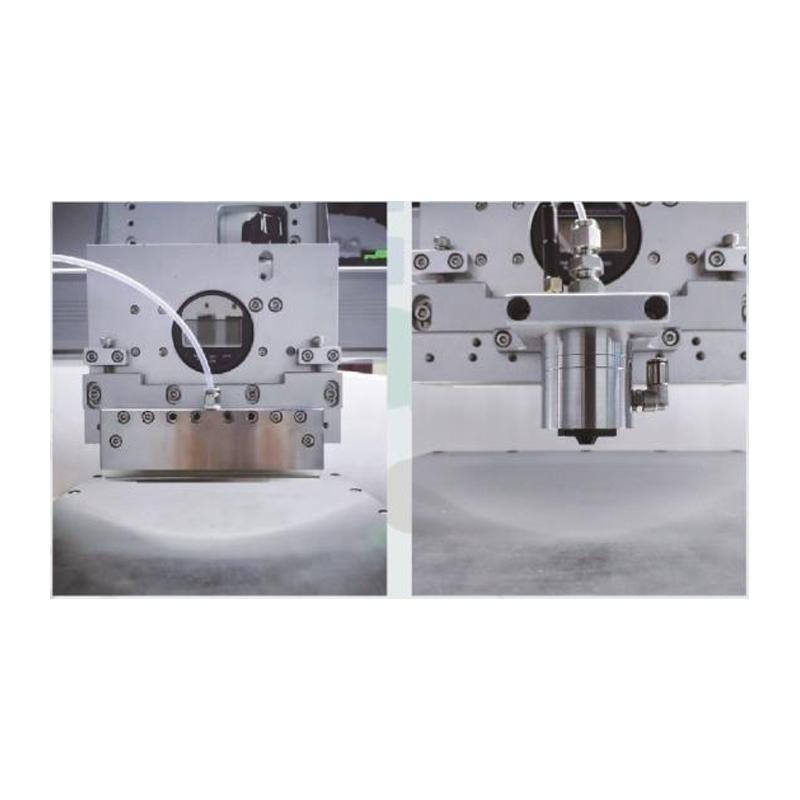

- Ultrasonic lame plating atomizing particle size

- 15-40 μm

- Lame plating width

- 2-20 mm

- Viscosity of liquid

- ≤30 cps

Introduction

It mainly includes desktop-level ultrasonic spraying system, desktop-level slit coating system, desktop-level roll-to-roll coating system, high-precision coating system, and small and medium-sized printed electronic coating equipment. Coating test, ink debugging, process research, small-scale sample preparation and research and development of various nano and sub-micron functional coating films for laboratories, university institutions and enterprise R&D centers.

The industries involved include proton exchange membrane fuel cell membrane electrodes, thin-film solar cells, perovskite solar cells, organic solar cells, transparent conductive films, biosensor coatings, wafer silicon wafer photoresists, circuit board fluxes in the field of microelectronics and semiconductors, AR anti-reflection and anti-reflection coatings for glass, hydrophilic coatings, hydrophobic coatings, thermal insulation films, transparent conductive films, superhydrophobic coatings, antibacterial coatings, as well as flexible transparent battery films, organic light-emitting diodes, touch screen films, solid capacitors, flexible wearables, Printing preparation of flexible stretches, chemical gas sensors, antistatic coatings, conductive inks, conductive adhesives, etc.

Product Features

1. Modular design, quickly realize the switching of different coating functions, one host, can achieve multi-function, set slit coating, scraper scraping, wire rod scraping, ultrasonic spraying in one, convenient for later function expansion;

2. Ink supply on demand, the amount of slit coating ink is as low as 1 ml, reducing waste and pollution;

3. It can be placed in the glove box, fume hood, etc. for operation;

4. The human-computer interaction interface compiled according to the characteristics of the printed electronic process, the large-size touch screen control, and the operation is simple;

5. Customize the coating process to facilitate the research of the coating process

6. Professional technical team, which can realize the continuous improvement and perfection of products;

7. The host system adopts new technology, and the key components (slit coating head, PLC control part, servo motor, grinding grade screw rod, etc.) are imported from abroad, and the supplier has a strict supplier management process, and all parts suppliers have been strictly audited and controlled to ensure the accuracy of the system and the reliability of the equipment;

8. It can integrate vacuum heating system, automatic ranging system, CCD imaging system, etc. according to user requirements, and has provided products for customers with various special requirements, and has accumulated rich experience in design and manufacturing;

9. Beautiful design, compact structure, fine workmanship, low operation and maintenance cost, internal design of storage rack and automatic exhaust system;

10. All kinds of desktop equipment have been applied to domestic (CN) universities, scientific research institutions and various R&D centers;

11. Provide after-sales training and process guidance, perfect after-sales service system and rich after-sales service experience, which can achieve fast and thoughtful after-sales service;

Application

For laboratories and enterprises film coating test, ink debugging, process research, small-scale sample preparation, etc. The industries involved include flexible transparent battery films, organic light-emitting diodes, flexible transparent conductive films for touch screens, solid capacitors, flexible wearables, flexible stretches, chemical gas sensors, antistatic coatings, conductive inks, and conductive adhesives.

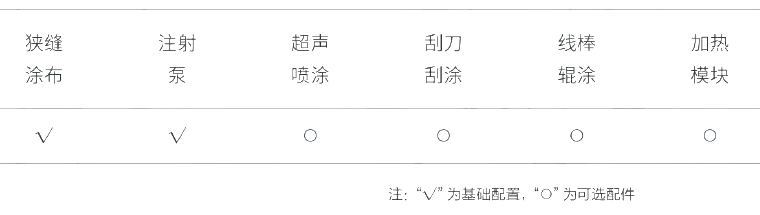

Features included

Slit coating, syringe pumps, ultrasonic spraying, scraper scraping, heating modules, vacuum adsorption modules

- 1Hot melt adhesive is applied on the film, how to choose the film coating machine?

- 2Principle and design of shunt pipe for coating hanger mold

- 3How to design lip for slit coating?

- 4Principle and method of mold positioning for slit coating

- 5Points to pay attention to in the design of support rollers for slit coating

- 6How to clean the coating mold?

- 7What type of coating is suitable for the wire mesh coater?

- 8Several stages and advantages and disadvantages of dip coating

- 9Installation of the material head of the slit coater [including video demonstration]

- 10How to Spreader Anode Slurry on Aluminum Foil

RD-Coater-S300

RD-Coater-S300