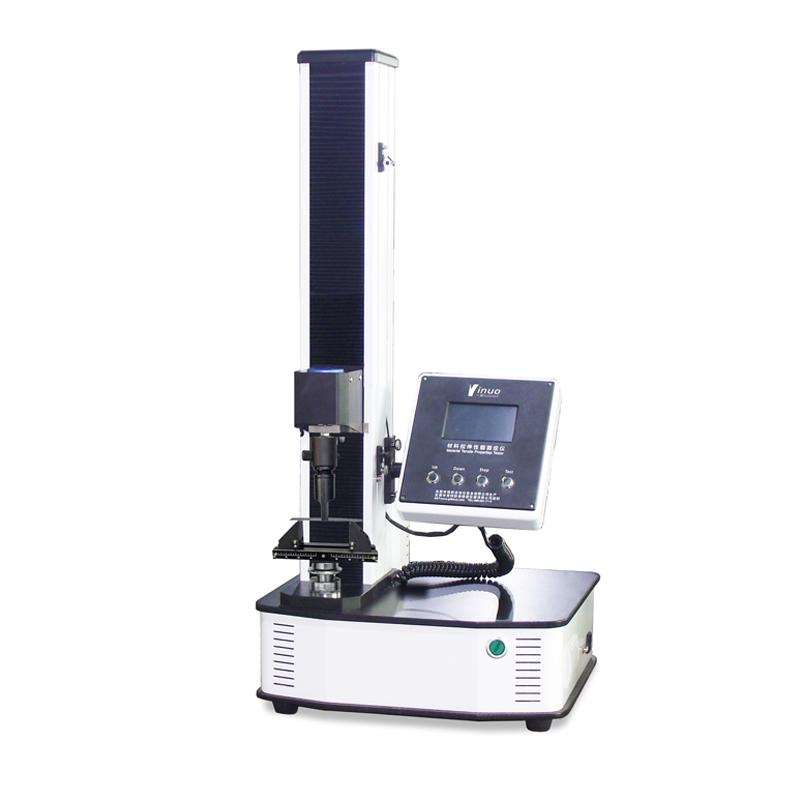

YINUO YN-KWY300 Microcomputer three-point flexural strength Tester

YiNuo YN-KWY300 Microcomputer three-point flexural strength TesterSPEC

YiNuo YN-KWY300 Microcomputer three-point flexural strength TesterDetails

YiNuo YN-KWY300 Microcomputer three-point flexural strength TesterPacking list

- SKU

- NB033160

- Measurement range

- (0~500N) (Other ranges can be customized)

- Accuracy grade

- Level 1

- Test force test range

- 0.4% ~ 100%FS

- Force Accuracy

- ±0.3%

- Indication Precision

- Error of indication/indication variability ≤ 0.3%

- Measurement range

- (0~600) mm (under 100mm test length)

- Test speed error

- (5~100)mm/min±0.2mm/min.

- Clip spacing positioning error

- ±0.2mm

- Moving chuck reset error

- ±0.05mm

- Force resolution

- 0.001N

- Force unit

- N, g, kg, Lb, kpa and other units

- Deformation resolution

- ≤0.1mm

- fixture

- Three-point bending fixture (width 50mm, lower support 180mm)

- clip spacing

- The test length is (1~ 600) [can be customized]

- stretching speed

- (1~ 550) mm/min stepless speed change

- return speed

- 150mm/min stepless speed change [ (1~ 550) mm/min adjustable]

- Transmission screw

- Adopting Taiwan, China single-column structure precision ball screw

- shell

- Made of aluminum alloy

- motor

- Stepping motor, 0~500mm/min stepless speed change

- Human Machine Interface

- 5.0In touch screen control

- printout

- Built-in modular integrated thermal printer

- communication output

- Built-in R232 interface, connected to computer software upgrade version (optional)

- exterior size

- 550*550*1100mm

- Weight

- About75kg

- Power supply Voltage

- 220v、50Hz

Instrument Usage

YN-KWY300 microcomputer flexural strength Tester is used to test the three-point bending resistance of various materials special testing equipment, the sample is placed on the two support points of the fixture, so that two equal moments are formed between the three contact points of the sample and the fixture, and the sample will be broken at the midpoint. The testing machine has tensile, peeling, deformation, compression retention force, puncture force, opening force, pulling force and other performance tests, and is widely used in paper and cardboard production industry, plastic products production industry, shoe material manufacturing industry, metal manufacturing industry, electronic appliances and other manufacturing industries.

Operating Principle

Test principle: The specimen is fixed between the two grips of the testing machine, and the two chucks move relative or corresponding according to the test mode, and the force value changes during the test are collected through the force value sensor located on the dynamic chuck and the displacement sensor built into the machine.

Enforce the standard

ISO 5628、SCAN P65、TAPPI T820、TAPPI T836、GB/T 14452

Technical characteristics

The level 1 test accuracy effectively guarantees the accuracy of the test results

7.0in touch screen curve display, free switching between Chinese and English, real-time display of various data and stretch curves;

Automatic return: After the test fracture is automatically identified, the movable beam automatically returns to the initial position at high speed

Built-in limit protection, overload protection, and other intelligent designs to ensure safe operation;

Test report: maximum force, tensile strength, tensile strength, bending strength, compressive strength, elongation at break, deformation, etc

Built-in R232 interface, optional connection to computer software, convenient data analysis management, saving, printing and other functions;

Using high-speed ARM processor, high degree of automation, fast data collection, automatic measurement, intelligent judgment function, safe and reliable;

The system has rich testing functions, equipped with more than 50 different specimen grips for users to choose, which can meet the testing requirements of more than 1,000 materials;

Product configuration

Standard Configuration:Host, fixture, power cord, manual, certificate, warranty card

Options:Customized fixtures, customized test procedures, optional professional software, and communication cables according to test requirements

Scope of application

| Test functionality | Expand your application |

| Pull | Tensile strength test, pull-pull force test, opening force test, adhesive tear force test, wire tensile force test, joint detachment force test |

| Peel force | 90 degree peel force test, 180 degree peel force test, adhesion peel test, cup lid peel force test |

| Puncture force | Partition puncture force test, film puncture force test, plastic bag puncture force test |

| Compression retention | Separator wet pressure holding test, carton support force, pressure holding force test |

| Bending deformation | Three-point stiffness test, four-point bending stiffness test, flexible packaging bag extrusion test, ampoule breaking force test |

YN-KWY300

YN-KWY300