-

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE -

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE -

China TBJ-A3 bar Vacuum chuck Lab Film Applicator Electric Coater$ 2029.00SE

China TBJ-A3 bar Vacuum chuck Lab Film Applicator Electric Coater$ 2029.00SE -

TQC AB4320 Automatic Film Applicator with Dual Channel Vacuum Table

TQC AB4320 Automatic Film Applicator with Dual Channel Vacuum Table -

TQC AB4220 Automatic Film Applicator with Vacuum Table$ 16568.00SE

TQC AB4220 Automatic Film Applicator with Vacuum Table$ 16568.00SE

zy TBJ-G-XB Automatic Film ApplicatorSPEC

zy TBJ-G-XB Automatic Film ApplicatorDetails

zy TBJ-G-XB Automatic Film ApplicatorPacking list

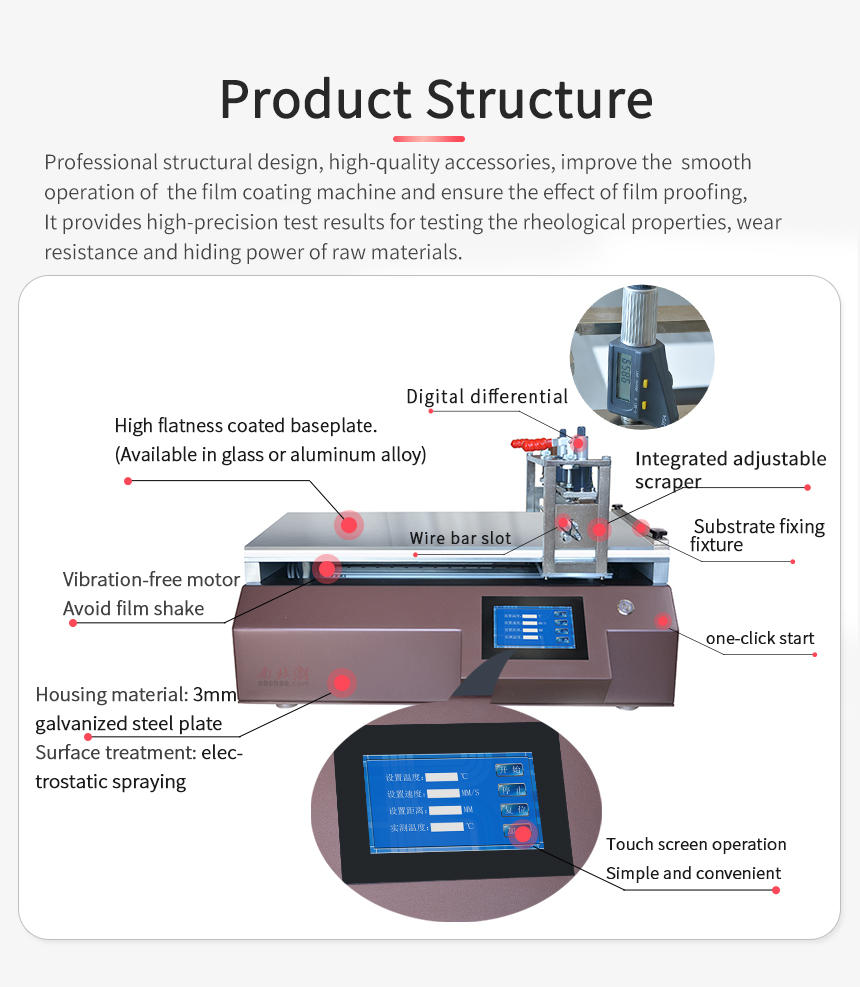

- SKU

- NB033804

- Spreader Accuracy

- ±0.001mm或±0.0001mm

- Spreader thickness range

- According to different rod specifications, 1.5μm~ 150μm

- Standard wire rod

- 1 China wire rod + 1 250mm long imported wire rod

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Coating size

- 190*400mm

- Vacuum Area

- 160 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Key control mode

- Touch screen control

- Host Power

- 220V 50Hz

- Dimensions

- 690*350*420mm

- Weight

- Net Weight 72KG

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- Vacuum pump size

- 380*180*280mm

- Customizable function

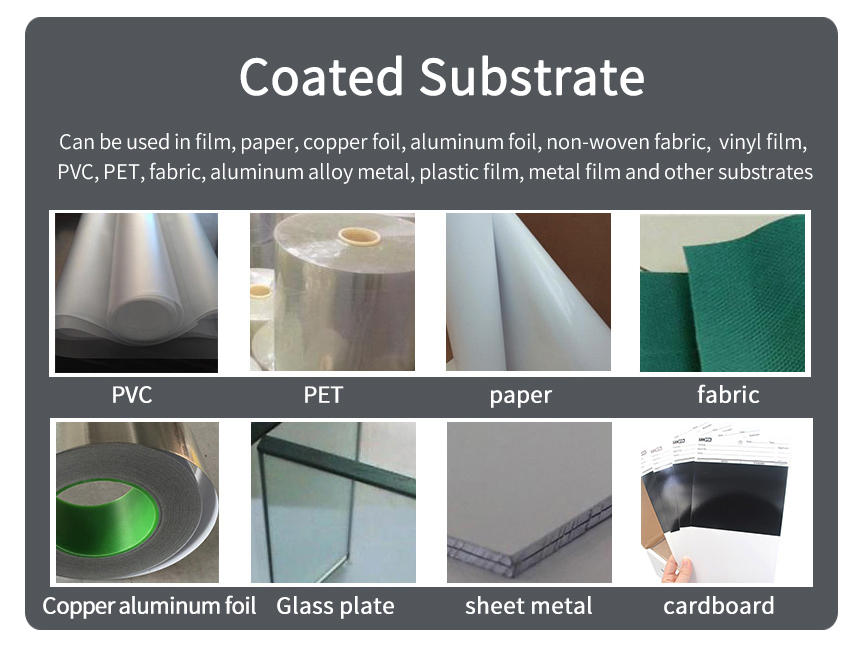

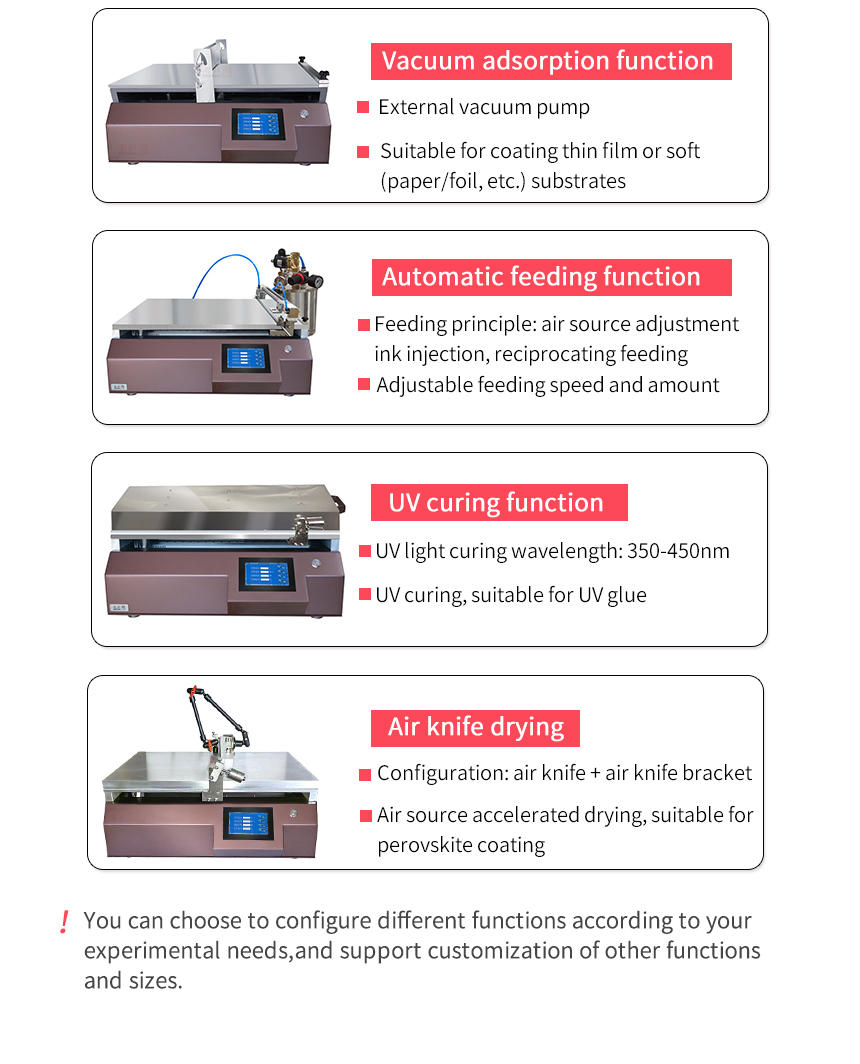

- Jet system device, UV solid-containing device, automatic inking system

- Optional

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven substrate thickness of Spreader)

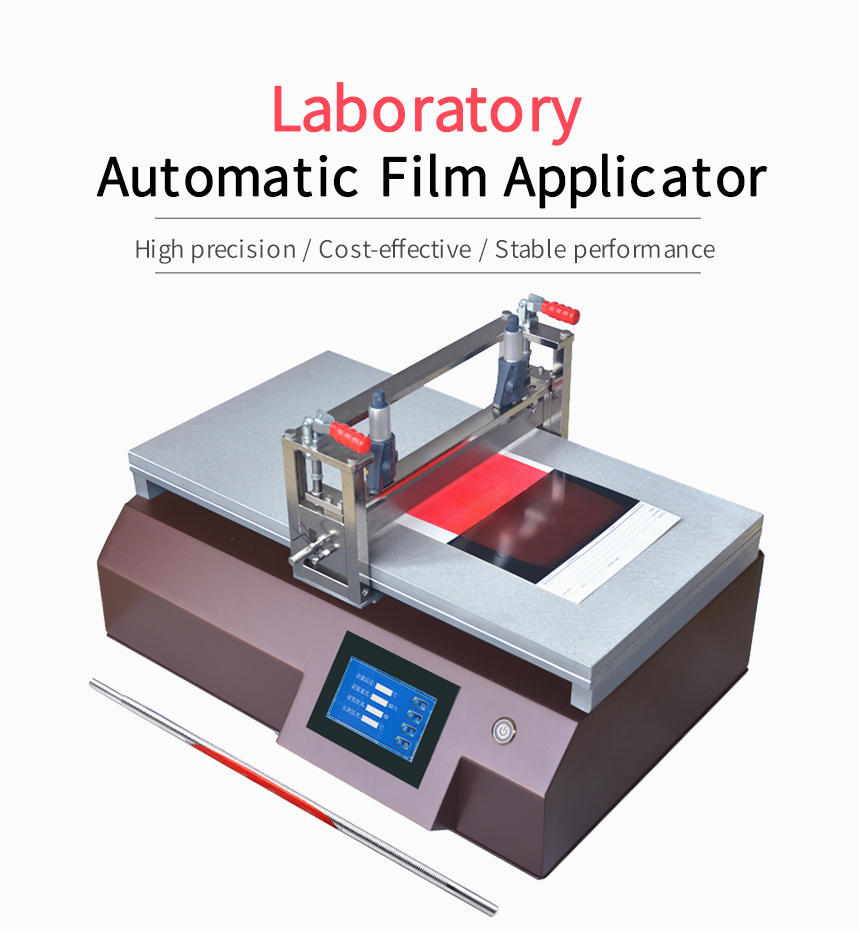

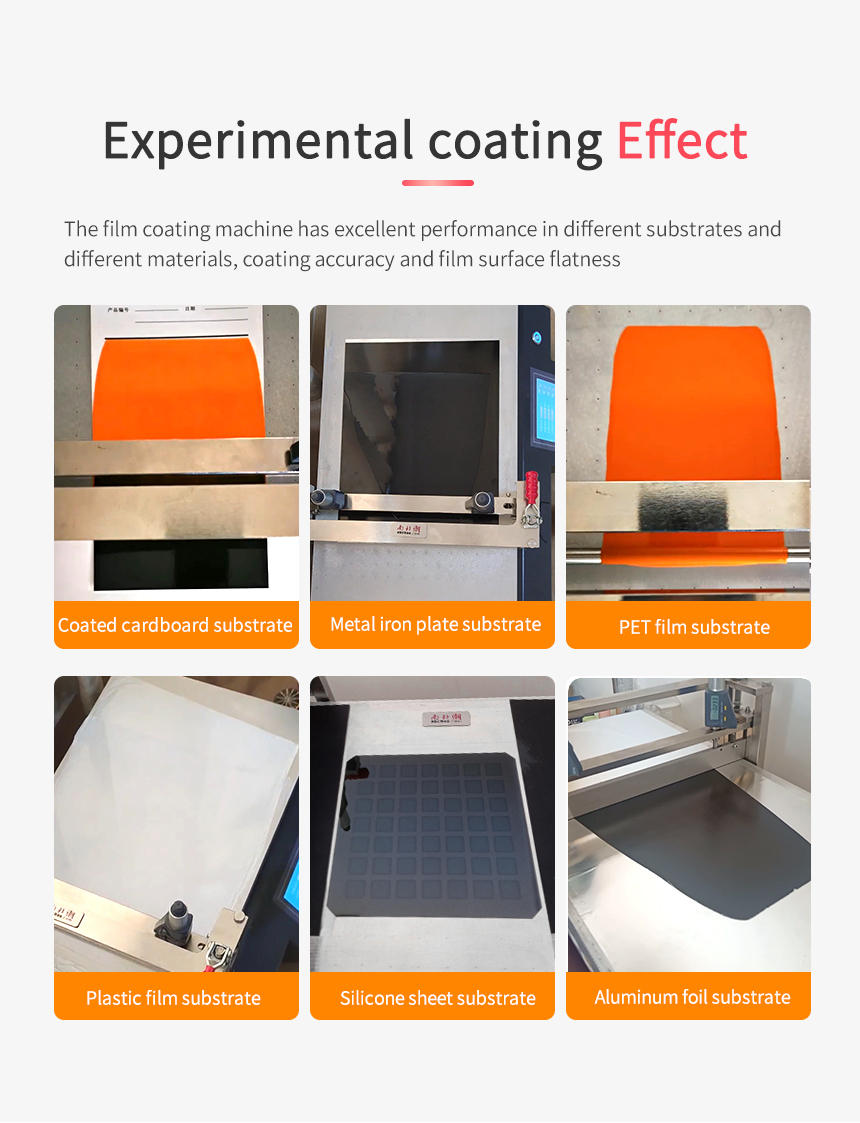

The touch laboratory TBJ-G wire rod coating testing machine is a newly developed and produced product according to the requirements of the national standard GB/T 9756-2018. It is carefully designed for coating precise wet films on different substrates. It can repeatedly and continuously prepare smooth and flawless test samples. After this equipment was put into the market, it has been favored by many familiar enterprises, R&D institutions, and colleges and universities.

Since the main factors that affect the coating film are the coating speed and the pressure exerted on the Film Applicator, the coatings applied manually are often inconsistent, especially the differences between different people are even greater, which gives Comparing test results between samples presents difficulties. Our company's automatic Film Applicator allows operators to easily apply precise wet films on different substrates, greatly improving the reproducibility of coating films.

TBJ-G-XB

TBJ-G-XB