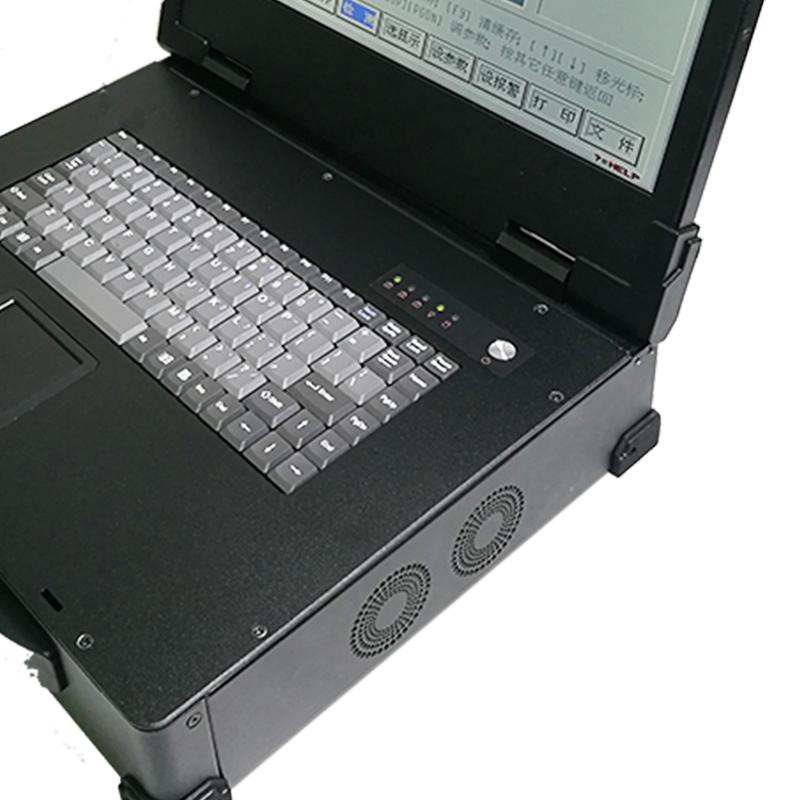

WENTAI WT-9HS Portable eddy current Flaw Detector Metal crazing detection 64Hz-2MHz

SEWenTai WT-9HS Portable eddy current Flaw DetectorSPEC

WenTai WT-9HS Portable eddy current Flaw DetectorDetails

WenTai WT-9HS Portable eddy current Flaw DetectorPacking list

- SKU

- NB034792

- Frequency range

- 64Hz~2MHz

- Gain

- 0~48db

- step distance

- 0.5db

- phase

- 0-360 degrees, 1 degree step

- Independent Optional Frequency

- Yes.

- mode setting

- Different styles of mode settings

- zero correction system

- Automatic zero correction system: the zero correction interval can be set

- Gain ratio

- 0.1~10.0

- Alarm output

- Sound and light alarm output

- Display mode

- Solid line, blanking

- blanking display coefficient

- 1~100

- Display

- liquid crystal display

- Power

- Lithium battery can be used for 6-8 hours at a time

product description

WT-9HS portable eddy current crack Detector is easy to carry and suitable for online and offline detection of cracks in metal pipes and bars, heat exchange tubes, and short-axis products. It uses an internal penetration probe to detect various defects, corrosion, and wall thickness reduction on the inner wall of the tube. Thin and other abnormalities. It has a relatively independent test channel that can drive a combined probe composed of absolute and differential coils. The detection channel collects data at the same time and is used to detect longitudinal cracks and transverse defects (such as barges) that appear in the production of metal products. It has high sensitivity to axial defects such as bumps and opening cracks. It can reliably detect cracks and damage to products caused by failures during the production process. The signals acquired by the detection channel can be displayed on the screen in real time as impedance plane diagram and time base scan diagram. It can adapt to the testing requirements of various metal products, and due to its fully digital design, it can establish multiple standard testing programs or professional systems in the instrument, which is convenient for users to call when changing product specifications. It is equipped with input and output controls. The interface facilitates the connection between the inspection site and various equipment and works synchronously to form a highly automated whole.

Principle

Eddy Current Testing (Eddy Current Testing) is one of many non-destructive testing (NDT) methods that applies the basic theory of "electromagnetism" as the basis for conductor testing.

Eddy current testing is to bring a conductor close to a probe that is powered by alternating current to establish an alternating magnetic field. The alternating magnetic field passes through the conductor and generates electromagnetic induction with it, creating eddy currents in the conductor. The eddy current in the probe conductor will also produce its own magnetic field. The effect of the eddy current magnetic field will also change the strength of the original magnetic field, which will lead to changes in Voltage and impedance. Therefore, when defects appear in the conductor or the measured metal material changes, the intensity and distribution of the eddy current will be affected. The change in the eddy current will in turn cause changes in the Voltage and impedance of the detection coil. Based on this change, the defects in the conductor can be indirectly known. existence and defects of metal materials.

Performance parameters

1. Frequency range: 64Hz-2MHz

2. Gain: 0-48db, step 0.5db

3. Phase: 0-360 degrees, step 1 degree

4. Independently selectable frequency

5. Mode settings of different styles

6. Automatic phase and amplitude analysis function

7. Automatic zero calibration system: the zero calibration interval can be set

8. Different styles of alarm area settings can be applied to various modes

9. Gain ratio (Y/X): 0.1-10

10. Automatic screen clearing/tracking impedance display

11. It has functions such as detection signal playback, access, etc.

12. Fast analog/digital electronic automatic balancing and dynamic tracking filtering

13. The operation interface is simple, intelligent and easy to operate.

14. Suitable for various probes: external pass-through probe, pen probe

15. Suitable for online and offline quality inspection of metal pipes, rods, and other metal parts manufacturers

16. Quick numbers

17. Non-equal amplitude and asymmetric phase alarm area setting

18. Multiple display modes: impedance, time base

19. Digital filtering

20. Sound and light alarm output

21. Automatic balancing time

22. Internal and external clock selection

23. A large amount of various detection programs and detection data can be stored

24. Eddy current signal playback expansion function

25. Automatically record and display defects

26. Display mode: solid line, blanking

27. Blanking display coefficient: 1ï½100

28. Cartesian coordinate system and polar coordinate system background selection

29. Automatic calendar and time display

30. LCD display

31. Power supply: lithium battery can be used for 6-8 hours once fully charged

32. Analog electronic balance

33. Measure the amplitude, phase and digital value of defects

Can be equipped with probe

environmental conditions

1. This machine is installed in a fixed place in the workshop for use.

2. Ambient temperature is minus 10~50℃

3. Environmental Relative Humidity: no more than 85%

4. Power supply: 220V (-20% ~ +20%)

WT-9HS

WT-9HS