RUNJIE RJ941 Surface Roughness Tester

RunJie RJ941 Surface roughness MeterSPEC

RunJie RJ941 Surface roughness MeterDetails

RunJie RJ941 Surface roughness MeterPacking list

- SKU

- NB034800

- Measurement range -Z axis (vertical)

- 160μm

- Measurement range -X axis (horizontal)

- 17.5mm

- Resolution -Z axis (vertical)

- 0.01μm/±20μm;0.02μm/±40μm;0.04μm/±80μm

- Measurement Items - Parameters

- Ra Rz==Ry(JIS) Rq Rt==Rmax Rp Rv R3z R3y Rz(JIS) Rs Rsk Rku Rsm Rmr

- Measurement Items - Standard

- ISO,ANSI,DIN,JIS

- Measurement Items - Graphics

- Linear dispersion,

- filter

- RC,PC-RC,Gauss,D-P

- Sampling length

- 0.25,0.8,2.5mm

- Evaluation length (ln)

- Ln= lr×n n=1~5

- Sensors - Measurement principles

- Displacement Differential Inductance

- Sensors - Stylus

- Natural diamond, 90 cone angle, 5 μm tip radius

- Sensors - Force Measurement

- <4mN

- Sensors - Guide

- Carbide, coasting direction radius 40mm

- Sensors - Coasting Speed

- lr=0.25, Vt=0.135mm/s; lr=0.8, Vt=0. 5mm/s; lr=2. 5, Vt=1mm/s;

- Error of indication

- Not more than +/- 10%

- Indication variability

- Not more than 6%

- Power

- Built-in lithium-ion rechargeable battery, charged with DC5V, 800mA charger

- Dimensions

- 141×55×40mm

- Weight

- Approx. 400g

- Operating Environment

- Temperature: - 20 ℃~ 40 ℃; Humidity: < 90% RH

- Storage and transportation environment

- Temperature: - 40 ℃~ 60 ℃; Humidity: < 90% RH

- Display range

- Ra Rq:0.005μm ~ 16μm

- Display range

- Rz; R3z ; Ry ; Rt; Rp; Rm 0.02μm ~ 160μm

- Display range -Sk

- 0 ~ 100%

- Display range -S; Sm

- 1mm

- Display range -tp

- 0 ~ 100%

product description

The portable roughness meter is a portable stylus surface roughness and shape measuring instrument, suitable for testing in workshop calibration stations, laboratories, measurement rooms and other environments. The measurement parameters comply with international standards and are compatible with the standards of some industrially developed countries such as the United States, Germany, Japan, and the United Kingdom. Measurement results can be displayed numerically and graphically on the LCD display or output to a printer.

The main function

â Mechatronics design, small size, light weight, easy to use;

â Use DSP chip for control and data processing, which is fast and has low power consumption;

â Large range, multiple parameters Ra, Rz, Rq, Rt.

â High-end machines add parameters such as Rp, Rv, R3z, R3y, RzJIS, Rs, Rsk, Rsm, Rku, Rmr;

â 128Ã64 OLED dot matrix display, digital/graphic display; high brightness and no Viewing Angle;

â The display is rich in information, intuitive, and can display all parameters and graphics;

â Compatible with multiple national standards such as ISO, DIN, ANSI, and JIS;

â Built-in lithium-ion rechargeable battery and charging control circuit, with high capacity and no memory effect;

â There is a remaining power indicator icon to remind the user to charge in time;

â Can display charging process instructions, so the operator can know the charging level at any time

â Continuous working time is more than 20 hours

âLarge-capacity data storage, capable of storing 100 sets of original data and waveforms.

â Real-time clock setting and display facilitate data recording and storage.

â With automatic sleep, automatic shutdown and other power-saving functions

â Reliable circuit and software design to prevent motor from running out

â Display measurement information, menu prompts, error messages and various prompts such as power on and off;

â Full metal shell design, sturdy, compact, portable and highly reliable.

â Can be connected to computers and printers;

â Can print all parameters or print any parameters set by the user.

â Optional curved surface sensor, small hole sensor, measurement platform, sensor sheath, extension

Applicable materials

It is suitable for processing industry, manufacturing, testing, commodity inspection and other departments. It is mainly suitable for on-site inspection of large workpieces and production lines, as well as outbound verification of testing, measurement, commodity inspection and other departments.

Fundamental

When this instrument measures the surface roughness of a workpiece, it first places the sensor on the measured surface of the workpiece, and then starts the instrument for measurement. The precision driving mechanism inside the instrument drives the sensor to slide along a straight line at a constant speed along the measured surface. The sensor passes through the built-in The sharp stylus feels the roughness of the measured surface. At this time, the roughness of the measured surface of the workpiece will cause the stylus to shift. This displacement will change the inductance of the sensor inductance coil, thus generating a signal at the output end of the phase-sensitive Detector. The analog signal is proportional to the roughness of the measured surface. After amplification and level conversion, the signal enters the data acquisition system. The DSP chip performs digital filtering and parameter calculation on the collected data. The measurement results are given on the display or can be displayed on the display. output on the printer and can also communicate with the PC.

Optional

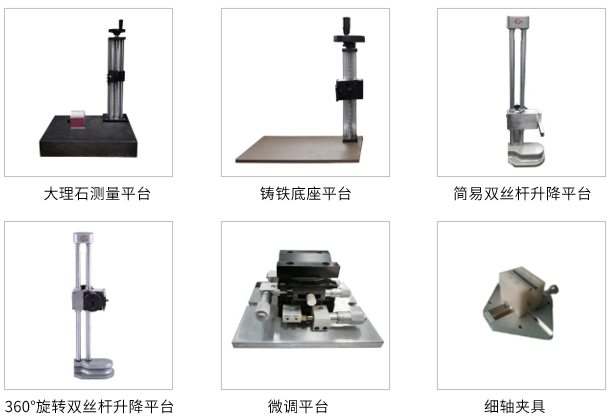

Measurement platform

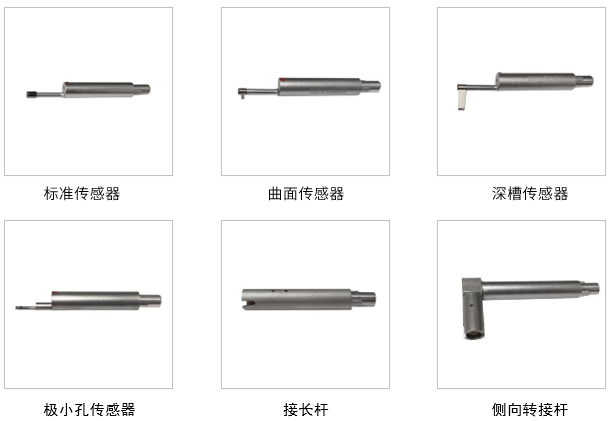

sensor

RJ941

RJ941