IPRE BH200M-W Computer-based Metallurgical Microscopy (excluding computer)

SEIpre BH200M-W Computer Metallurgical MicroscopySPEC

Ipre BH200M-W Computer Metallurgical MicroscopyDetails

Ipre BH200M-W Computer Metallurgical MicroscopyPacking list

- SKU

- NB035848

- Optical inspection system

- Optical inspection system for color difference correction

- observation tube

- 30 ° tilt, hinged trinocular observation cylinder, 360 ° swirl/spin, pupil distance adjustment range: 50-75mm, bilateral vision adjustment: +/- 5 diopters, fixed spectral ratio, binocular: trinocular = 80:20.

- eyepiece

- High eye point and large field of view flat field eyepiece PL10X/18mm

- Long distance flat field color difference objective

- LMPL5X /0.13 WD15.5mm,LMPL10X/0.25 WD8.7mm,LMPL20X/0.40 WD8.8mm,LMPL50X/0.60 WD5.10mm

- converter

- Internal positioning four-hole converter

- Focusing mechanism

- Low hand position coarse micro coaxial focusing mechanism, fine-tuning Accuracy of 0.002mm, with anti-sliding adjustment elastic device and mechanical upper limit device.

- stage

- Compound double-decked mechanical moving platform, table size 140 * 132mm, moving range: 76mmX50mm, Accuracy 0.1mm.

- Reflection lighting system

- Reflection Cora lighting, adaptive wide Voltage 100V-240V, 5W LED warm color, Light intensity continuously adjustable, with variable aperture diaphragm and field diaphragm, field diaphragm center adjustable

- Metallographic analysis system

- FMIA2024 genuine metallographic analysis software, 5 million Sony chip camera device, 0.5X adapter mirror interface, micrometer.

- eyepiece

- High eye point large field of view flat field eyepiece PL10X/18mm, with micrometer, high eye point large field of view eyepiece WF15X/13mm, high eye point large field of view eyepiece WF20X/10mm

- objective lens

- Long distance flat field color difference elimination objective LMPL100X/0.80 WD2.0mm

- converter

- Internal positioning five-hole converter

- Transmission lighting system

- Adaptive 100V-240V wide Voltage, single high-power 5W LED, warm color

- condenser

- Abbe condenser, numerical aperture N.A.1.25.

- Polarized Accessories

- Polarizer insert, polarizer insert

- Color filter

- Yellow, green, blue, neutral color filters

- computer

- HP Business Jet (computer optional)

Introduction

The BH200M-W computerized metallurgical microscope is a trinocular, upright metallographic microscope, which can provide superior image quality and stable operating system, easy operation and complete accessories. It is widely used in teaching and scientific research, metallographic analysis, industrial testing and other fields.

Focusing mechanism

Coarse and fine-tuning coaxial, with mechanical upper limit and tightness adjustment device, coarse adjustment stroke 25mm, fine-tuning accuracy 0.002mm.

Mechanical moving platform

Composite double-layer mechanical mobile platform, low hand position coaxial adjustment, and attached to the mechanical platform 180mm*145mm flat platform, convenient for placing larger size samples.

Lighting system

Epi-Kola illumination, and the design of anti-reflective structure, effectively prevent the interference of reflected light, so that the imaging is clearer, and the field of view contrast is better.

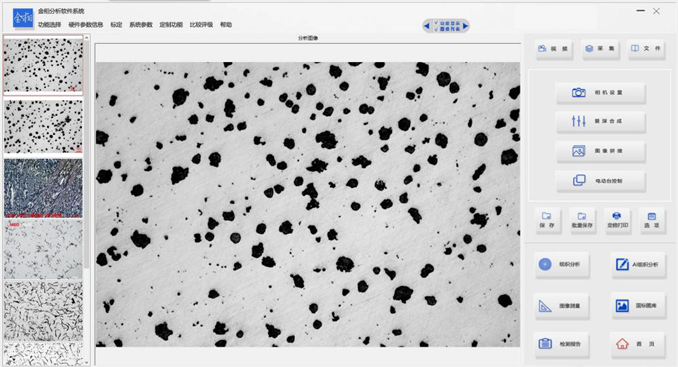

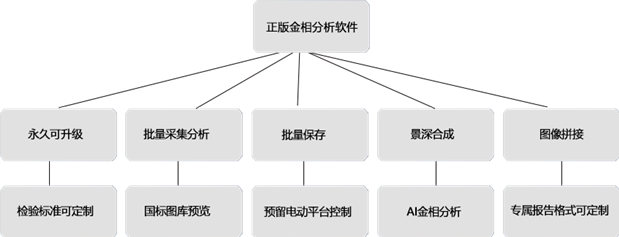

FMIA2024 genuine metallographic image analysis software

FMIA2024 metallographic image analysis software is our company combined with the current foundry enterprises, auto parts enterprises, heat treatment enterprises, bearing steel industry, power system industry, railway parts industry, and the needs of various testing companies for metallographic testing, in order to improve the product qualification rate and help the improvement of the laboratory inspection level, we collect the needs of experts and teachers in various industries, and develop a new set of metallographic image analysis software system.

The FMIA2024 version of the metallographic image analysis software has been completely revised and upgraded, the system covers a large number of metallographic detection standards at home and abroad, integrating quantitative analysis and qualitative analysis, adding the function of depth of field synthesis and image field stitching, the interface is simple, you can continuously shoot multi-field images, concentrate on the organization and analysis of the image, the operation is more convenient, and the cumbersome steps of the previous software are omitted, so that the detection is faster and more efficient.

Create a new set of "professional-accurate-efficient" metallographic analysis tool system to make metallographic analysis simpler.

The software system national standard library contains hundreds of categories, which basically cover the commonly used metallographic standards and meet the requirements of metallographic analysis and inspection of most units. According to the needs of different industries, designate relevant categories to meet the testing requirements of the industry. Call all modules for free for life, and upgrade the standard for free for life.

In view of the increasing number of new materials and imported grade materials, materials and evaluation criteria that have not yet been entered in the software can be customized and entered individually

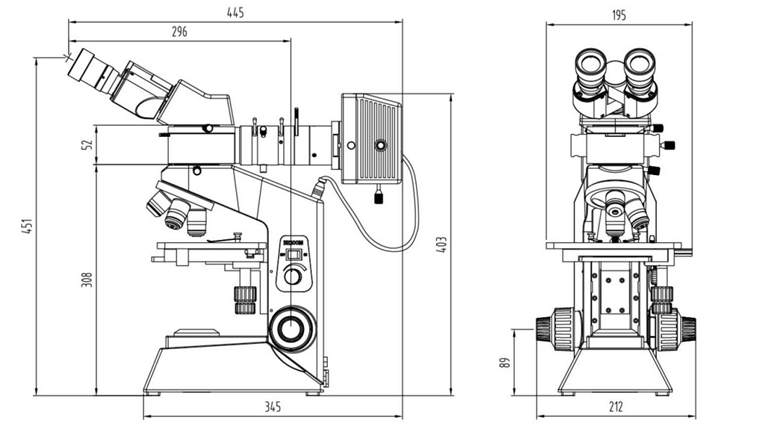

Dimensions of BH200M-W computerized metallurgical microscope

- 1GB/T 44293-2024《Image measurement method for numerical aperture of microscopic objective》

- 2JJF 1914-2011《Calibration Specification for Metallurgical Microscopes》

- 3GB/T 10561-2023《Determination of content of nonmetallic inclusions in steel—Micrographic method using standard diagrams》

- 4GB/T 7216-2023《Metallographic test for grey cast iron》

BH200M-W

BH200M-W