Film Small Film Applicator Vacuum adsorption function, can be coated with catalyst 11 μm

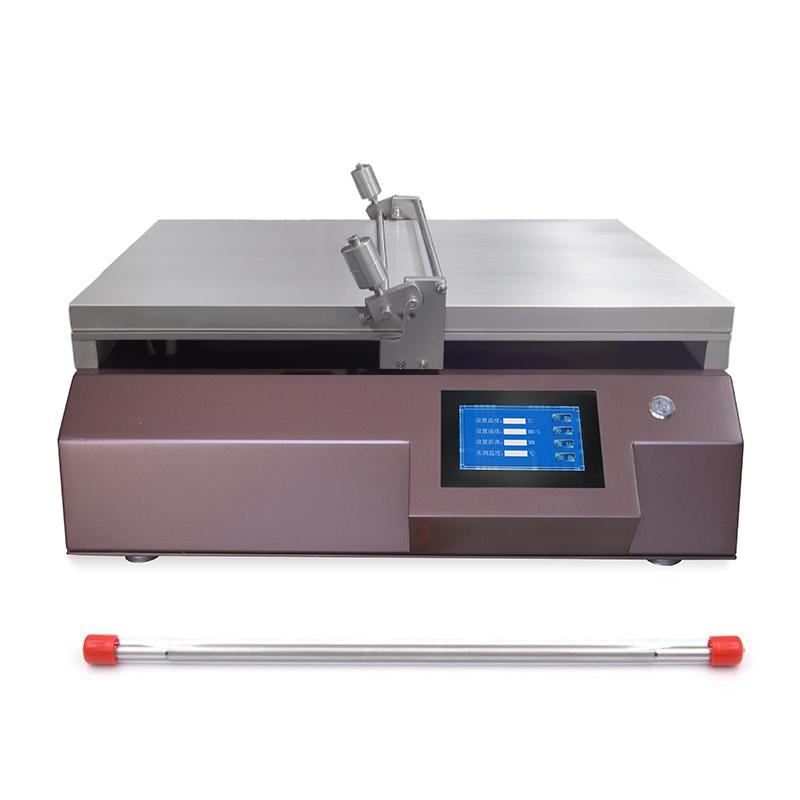

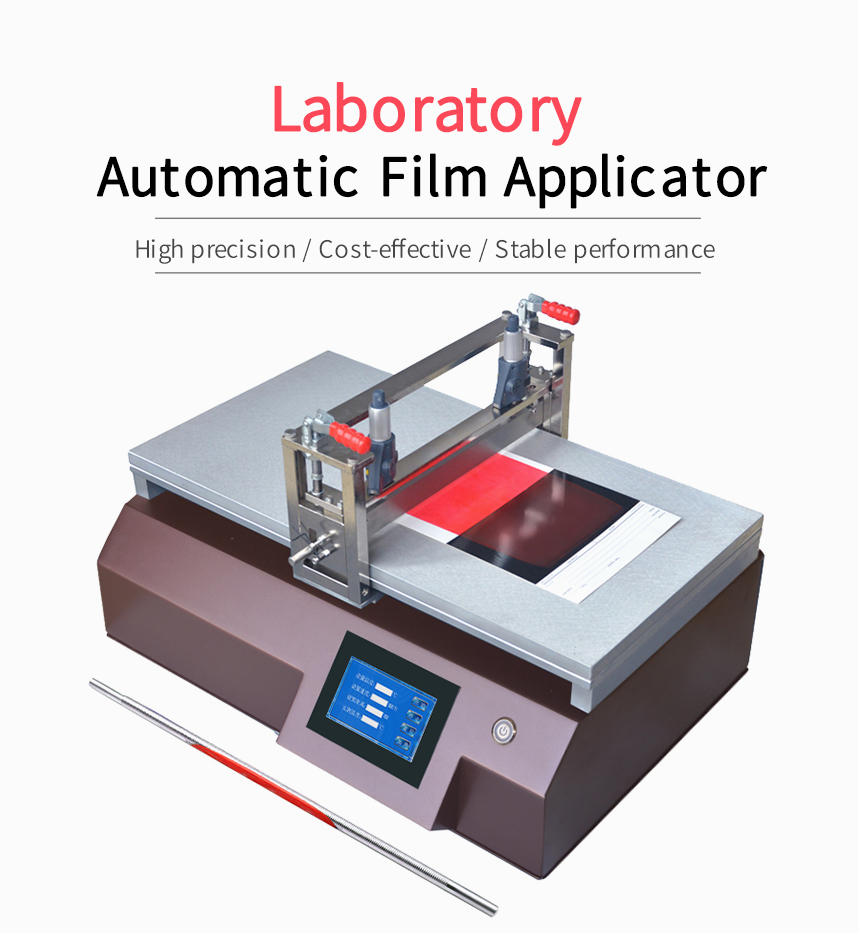

TBJ-A3 film small film Applicator is a laboratory film Applicator with vacuum adsorption function, especially suitable for film substrate coating, standard with an 11 micron imported Mayer Rods, Drawdown Vacuum Plate size is 300 * 400mm.

Model:

zy

Manufacturer authorization

Similar products

-

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE -

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE -

HUINUO TM1200 Wire Bar film Coater with Vacuum Table$ 2734.00SE

HUINUO TM1200 Wire Bar film Coater with Vacuum Table$ 2734.00SE -

China TBJ-A3 bar Vacuum chuck Lab Film Applicator Electric Coater$ 2029.00SE

China TBJ-A3 bar Vacuum chuck Lab Film Applicator Electric Coater$ 2029.00SE -

China TBJ-A3 (custom) bar Vacuum chuck laboratory Coater

China TBJ-A3 (custom) bar Vacuum chuck laboratory Coater

zy TBJ-A3+RDS5# Automatic Film ApplicatorSPEC

zy TBJ-A3+RDS5# Automatic Film ApplicatorDetails

zy TBJ-A3+RDS5# Automatic Film ApplicatorPacking list

- SKU

- NB035865

- Coating method

- Wire Rod Coating

- Coating size

- 300*400mm

- Application width

- 300mm

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Spreader thickness range

- With 1 China wire rod and 1 imported wire rod with 11 μm film

- Temperature display Accuracy

- ±2℃

- Vacuum pump configuration

- external

- Vacuum Area

- 300 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Key control mode

- Touch screen control

- Regulator display Accuracy

- ±0.001mm

- Display

- digital

- Total power consumption

- 2060W

- Host Power

- 220V 50Hz

- Dimensions

- 690*410*520mm

- Machine Weight

- 65Kg

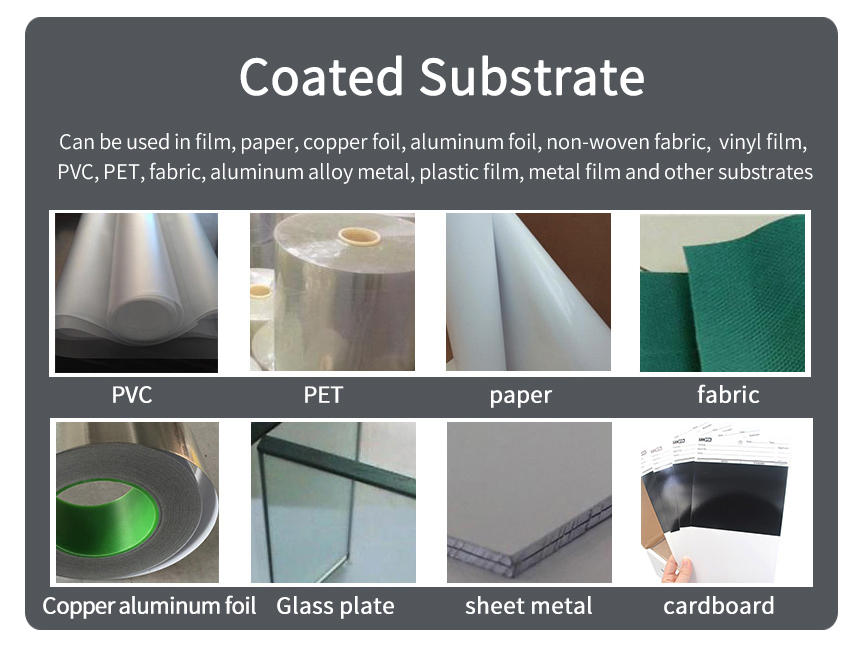

- Bottom plate material

- aluminum alloy

- Vacuum pump size

- 380*180*280mm

- Optional

- Substrate fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven substrate thickness of Spreader)

- Customizable function

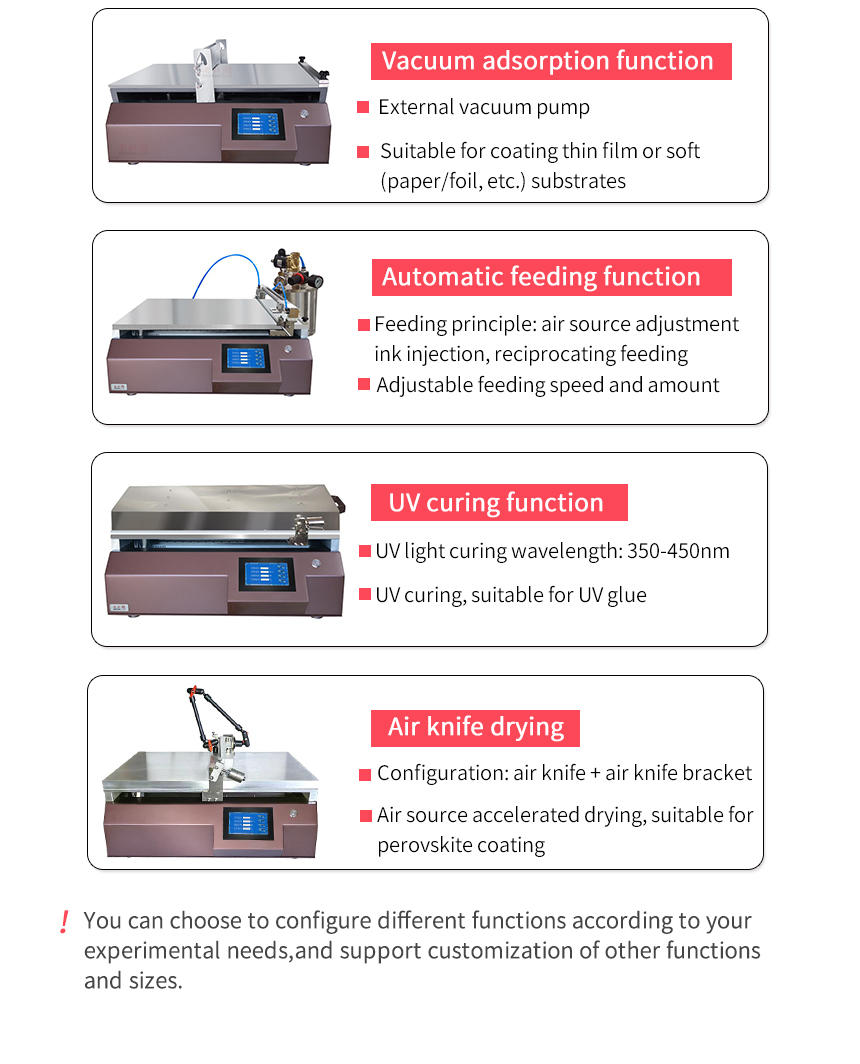

- Jet system device, UV solid-containing device, automatic inking system

- speed control

- Infinitely variable speed

TBJ-A3+RDS5#

Automatic Film Applicator

product description

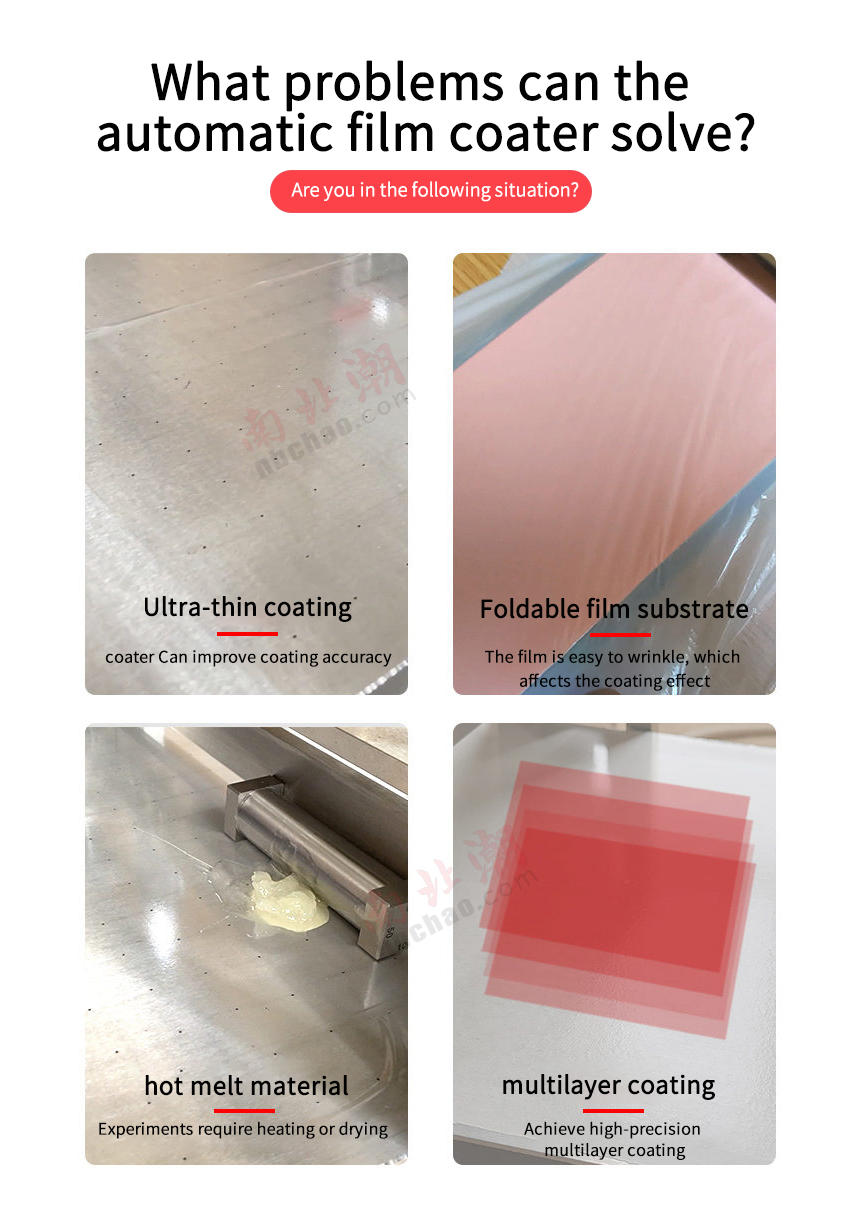

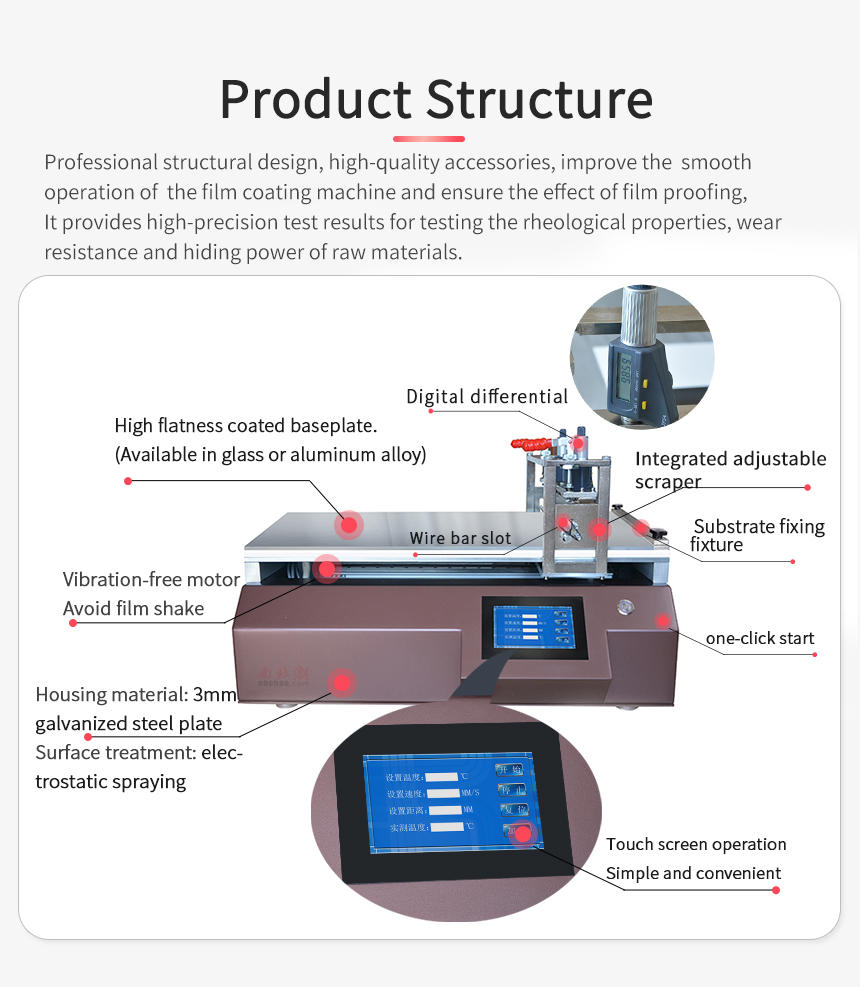

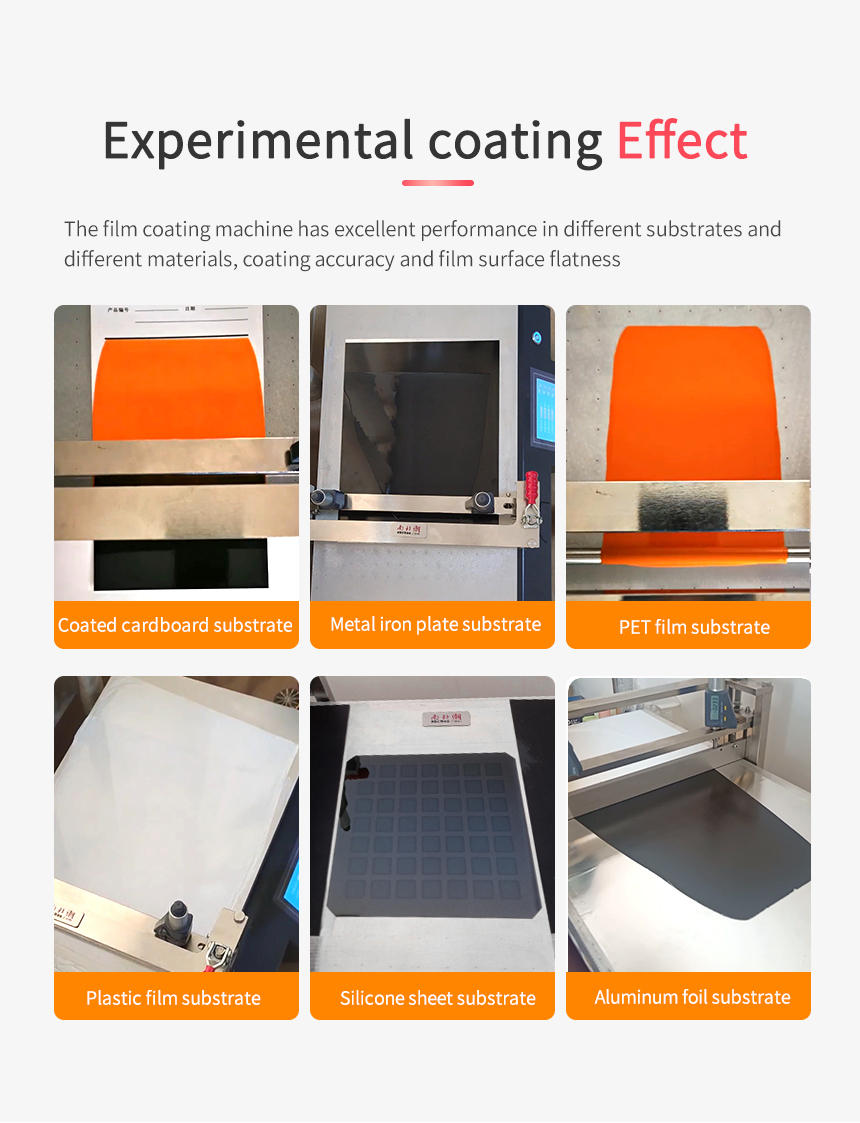

TBJ-A3 small thin film coating machine is a laboratory coating machine with vacuum adsorption function, especially suitable for coating film substrates. It is equipped with an 11 micron imported wire rod coater as standard, and the vacuum plate size is 300* 400mm.

The Touch Laboratory TBJ-A wire rod coating testing machine is a newly upgraded product that is carefully designed for coating precise wet films on different substrates. It can repeatedly and continuously prepare smooth, flat and flawless films. After testing samples, this equipment has been favored by many familiar enterprises, R&D institutions, and colleges and universities since it was put into the market.

Optional

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

Knowledge

TBJ-A3+RDS5#

TBJ-A3+RDS5#