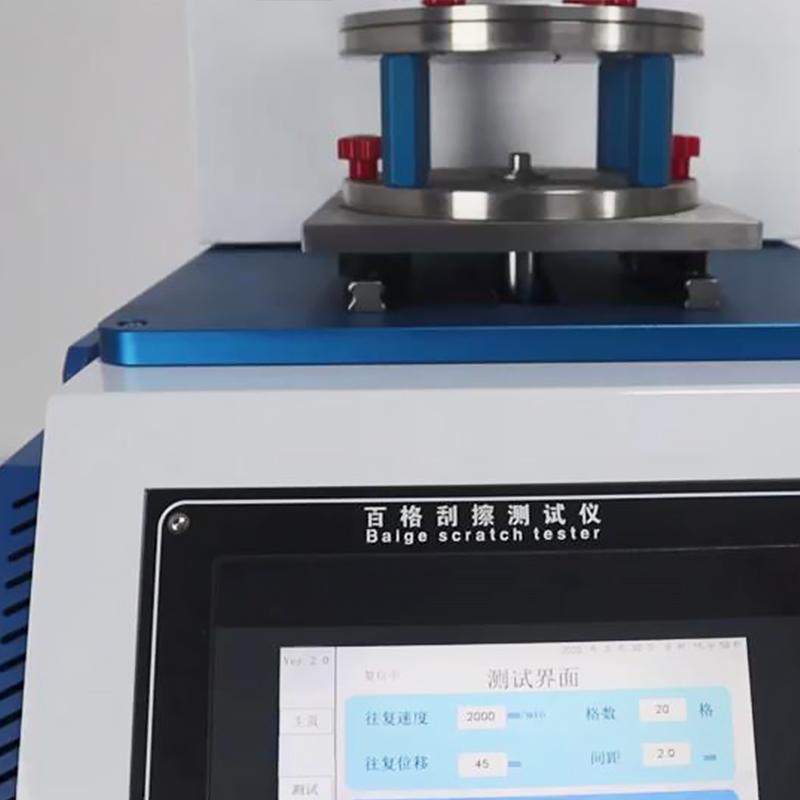

HUITAO CSI-110 hundred grid cross scratch resistance Tester, automotive interior material inspection

SEhuitao CSI-110 100 grid cross scratch resistance TesterSPEC

huitao CSI-110 100 grid cross scratch resistance TesterDetails

huitao CSI-110 100 grid cross scratch resistance TesterPacking list

- SKU

- NB035895

- range of travel

- 10-200mm

- Speed range

- 10-200mm/s

- speed buffering

- 10±1mm

- Diameter of metal scraper head

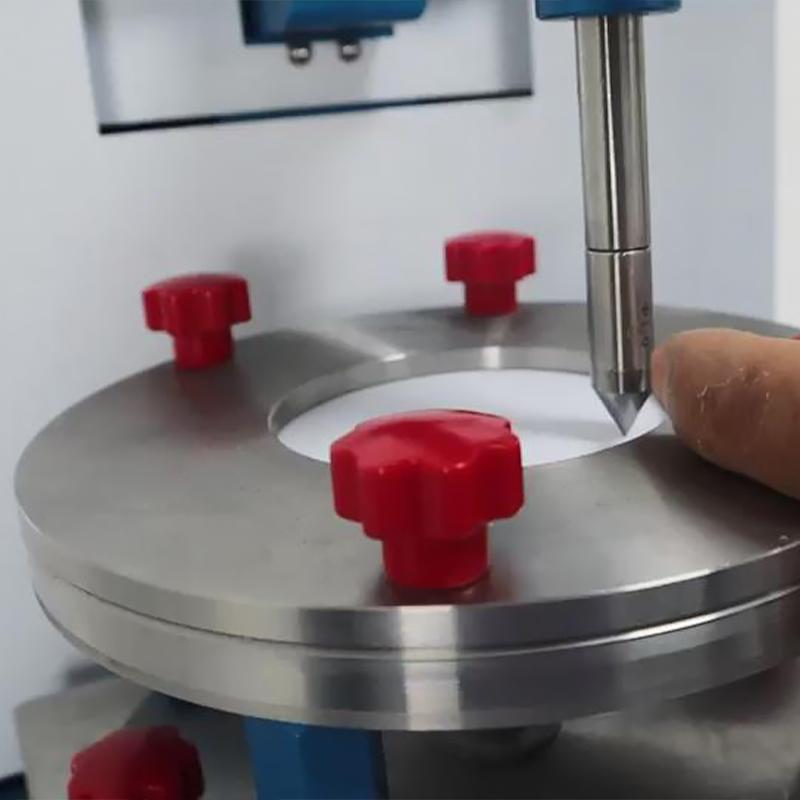

- 0.5mm、0.75mm、1mm(Erichsen318)、3mm、5mm、7mm

- Metal scraper head material

- Tungsten Carbide, Sapphire, Carbide

- Pressurized Weight and total Weight of scraping components

- 5N, 10N,, 15N, (can be arbitrarily selected and customized) Mass error does not exceed 1%

- Power

- AC220V±10%,50Hz

Application

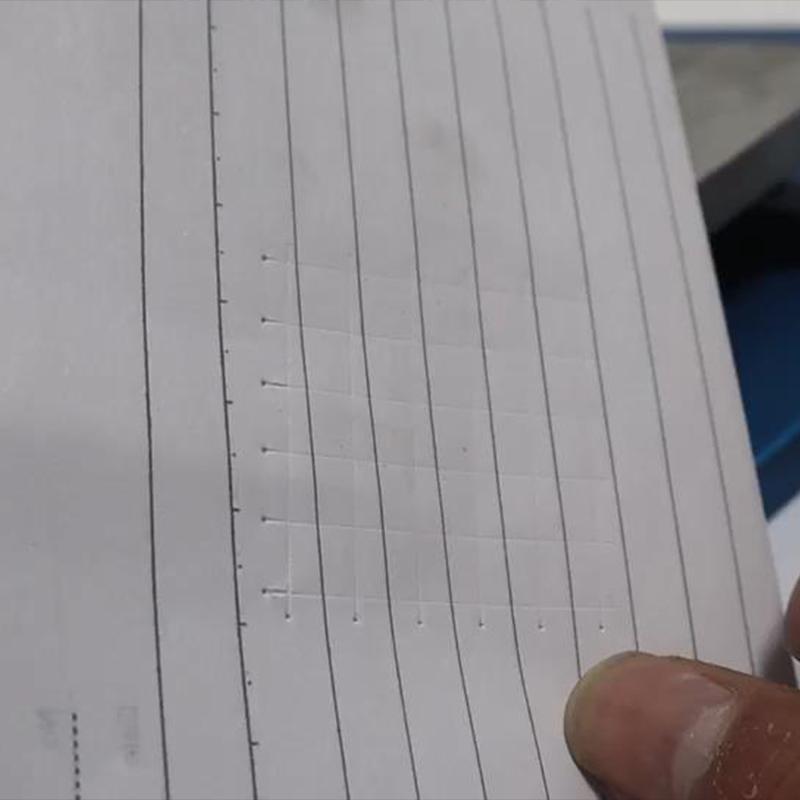

Baige Cross Scratch Tester This instrument is suitable for testing the scratch resistance of various automotive interior materials, such as plastics, rubber, leather, fabrics, coated materials, non-coated materials and other composite materials. The scratch resistance Tester is suitable for testing the scratch performance of various automotive interior materials. The instrument integrates three domestic (CN) test standards (five-finger scratch method, 100-grid method, and plastic finger scratch method).

Scratching principle

This test method is used to test the ability of surface materials to resist damage caused by scratching fingers. According to the nails or other hard objects that may come into contact with the material, scraping fingers of different materials are used to act on the surface of the sample with a certain pressure according to the specified direction, stroke, and speed, and the scraping head and the sample make relative motion, resulting in One-way, non-reciprocating linear scraping track, the scratches are kept parallel. The final evaluation of the scratch sensory grade of the material, the color difference between the scratched area and the unscratched area, or the minimum scratch force when the sample surface is damaged.

Standards

GM 14688 (Method A)

GM 14688 (Method B)

PV 3952--3951-3954 -3974 -3572 Volkswagen standard

GB/T 9286-97/ISO 2409ISO2409

GB/T 9279-2007/ISO 1518:1992

Q/SQR S1-16-2016 Chery Standard

Q/SQR T1-64 Chery standard (10N for hard material, 5N for soft material)

Instrument characteristics

1. The instrument is composed of a motor drive mechanism, a scraping component, a sample clamping and fixing device, etc.

2. The scraping components include scraping brackets, scraping fingers, scraping finger positioning sleeves, pressurizing devices (weights and weight support rods), etc.

3. The instrument can freely install, replace, and disassemble scraping fingers of different specifications, and can perform uniform one-way linear scraping movement under different loads.

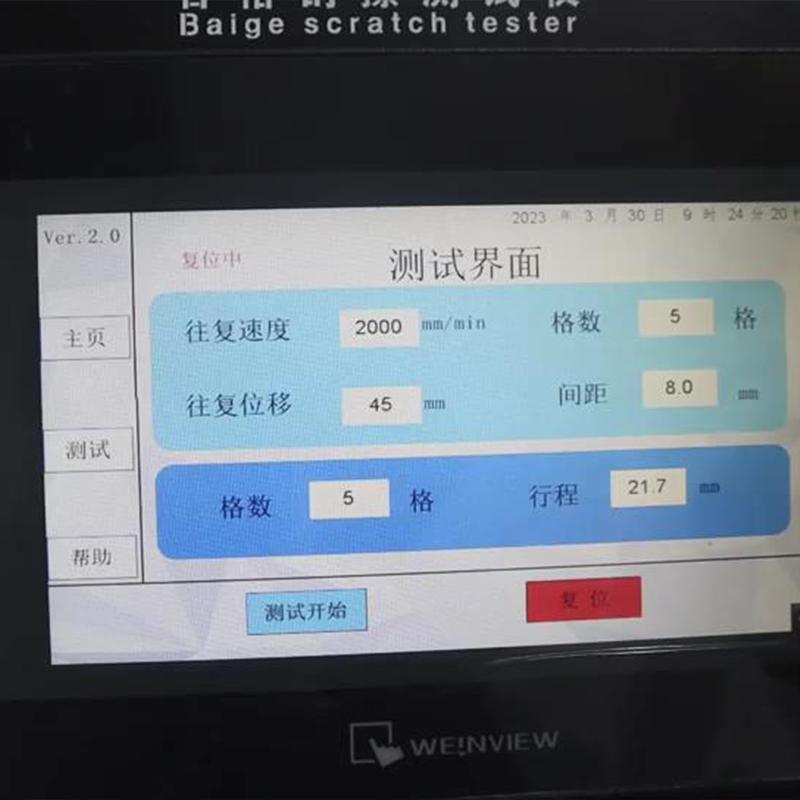

4. The embedded system and man-machine interface are used to automatically control the test process, and the precision servo motor and ball screw drive are used, which play a decisive role in controlling the scraping speed under the relevant standards.

5. Tungsten carbide is used as the scraping finger to increase the service life of the instrument.

6. Made of aluminum alloy and stainless steel, the appearance is simple, light and corrosion-resistant.

CSI-110

CSI-110