CHINA experimental small Coater heating oven PVA composite membrane experiment

-

China Laboratory Film Applicator Vacuum chuck + bar + Portable Drawdown blade Scraping Machine TBJ-GDO-GCXB$ 2468.00SE

China Laboratory Film Applicator Vacuum chuck + bar + Portable Drawdown blade Scraping Machine TBJ-GDO-GCXB$ 2468.00SE -

Kenton DHG-9070C digital precision drying oven 70L with independent temperature limiter$ 497.00SE

Kenton DHG-9070C digital precision drying oven 70L with independent temperature limiter$ 497.00SE -

Kenton DHG-9070 Precision thermostatic drying oven 70L with independent temperature limiter$ 576.00SE

Kenton DHG-9070 Precision thermostatic drying oven 70L with independent temperature limiter$ 576.00SE

zy TBJ-X2+DHG-9070 Automatic Film ApplicatorSPEC

zy TBJ-X2+DHG-9070 Automatic Film ApplicatorDetails

zy TBJ-X2+DHG-9070 Automatic Film ApplicatorPacking list

- SKU

- NB036923

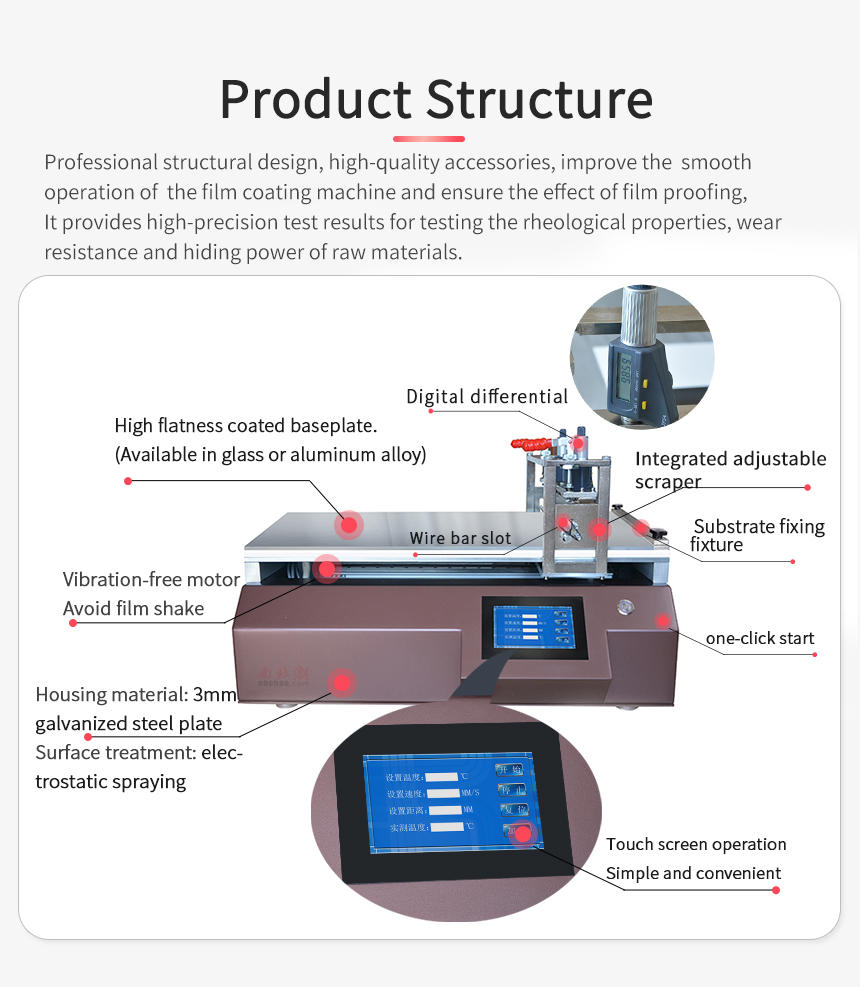

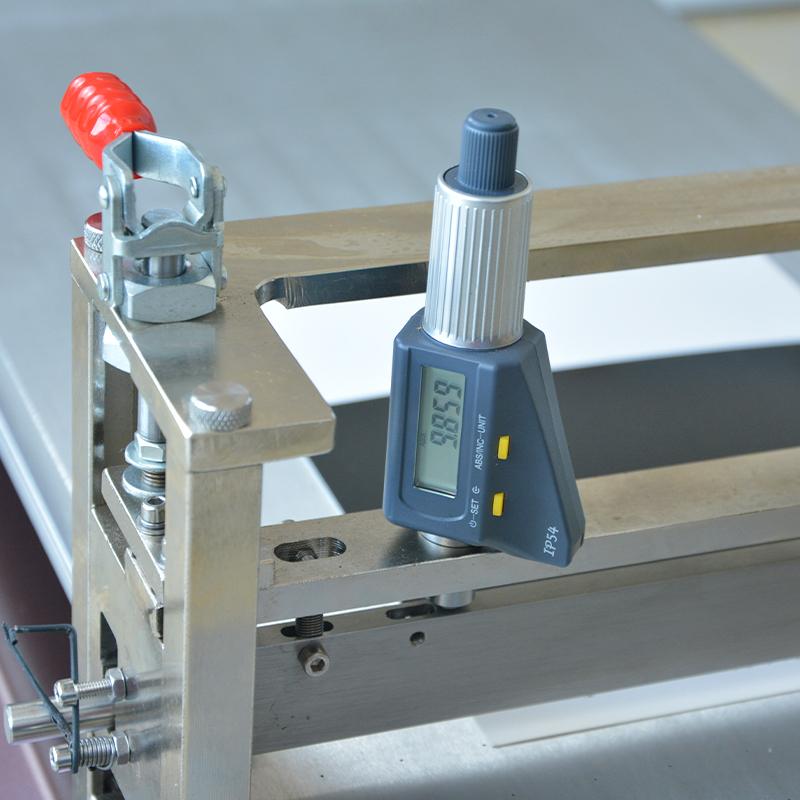

- Spreader Accuracy

- ±0.003mm

- Spreader thickness range

- 0~10Mm drawdown blade can be lifted

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Coating size

- 300*400mm

- Spreader speed

- Digital display, different speeds

- Vacuum Area

- 300 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Vacuum pump size

- 380*180*280mm

- Coating rod specification

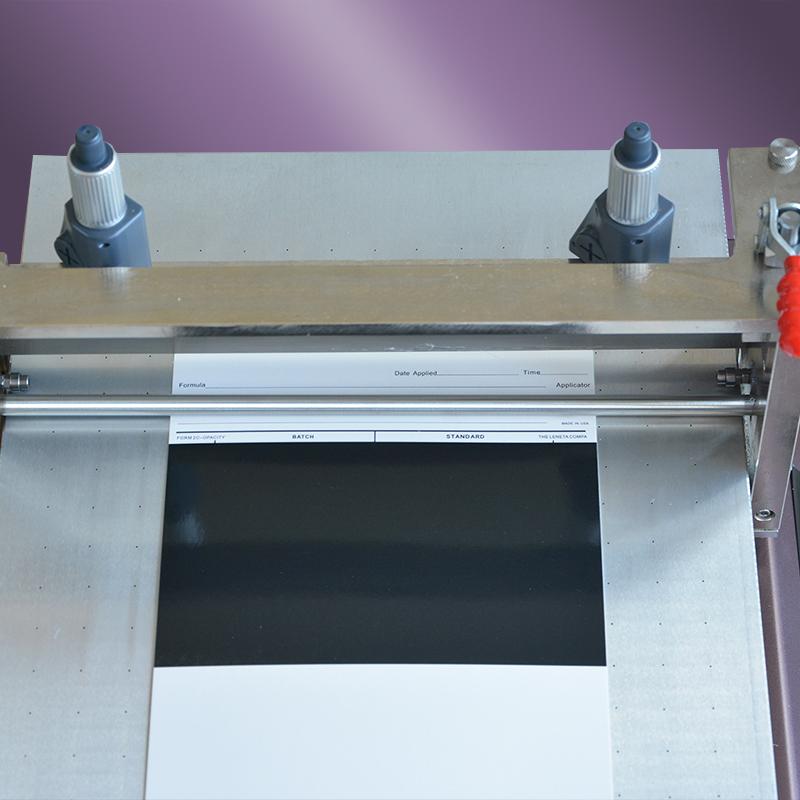

- Accuracy 0.001mm, effective application width 300mm (Spreader thickness is determined according to the bar model)

- Coater Power

- Voltage 220V 50HZ

- Coater machine Volume

- 630 * 410 * 520 (L * W * H)

- Coater Weight

- Net Weight 65KG

- speed control

- Infinitely variable speed

- Coater floor material

- aluminum alloy

- Coater Accessories

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven substrate thickness of Spreader)

- Spreader Accuracy

- 0.001mm

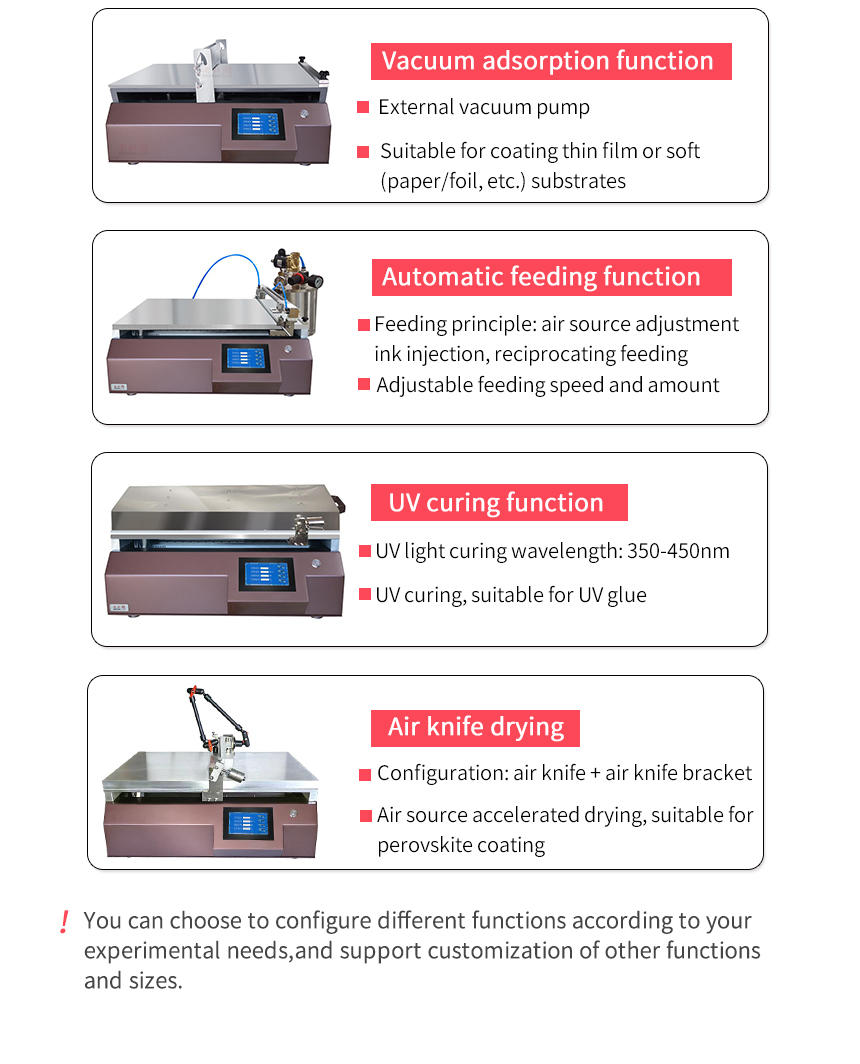

- Coater customizable function

- Jet system device, UV solid-containing device, automatic inking system

- Oven Power

- 220V 50Hz

- Oven Power Consumption

- 1000W

- Oven Temperature range

- Room temperature + 10~300 ℃

- Oven Temperature Fluctuation

- ±1℃

- Oven Interior size

- 450*350*450mm

- Oven Dimensions

- 620*680*620mm

- Oven shelf (std.) block

- 2

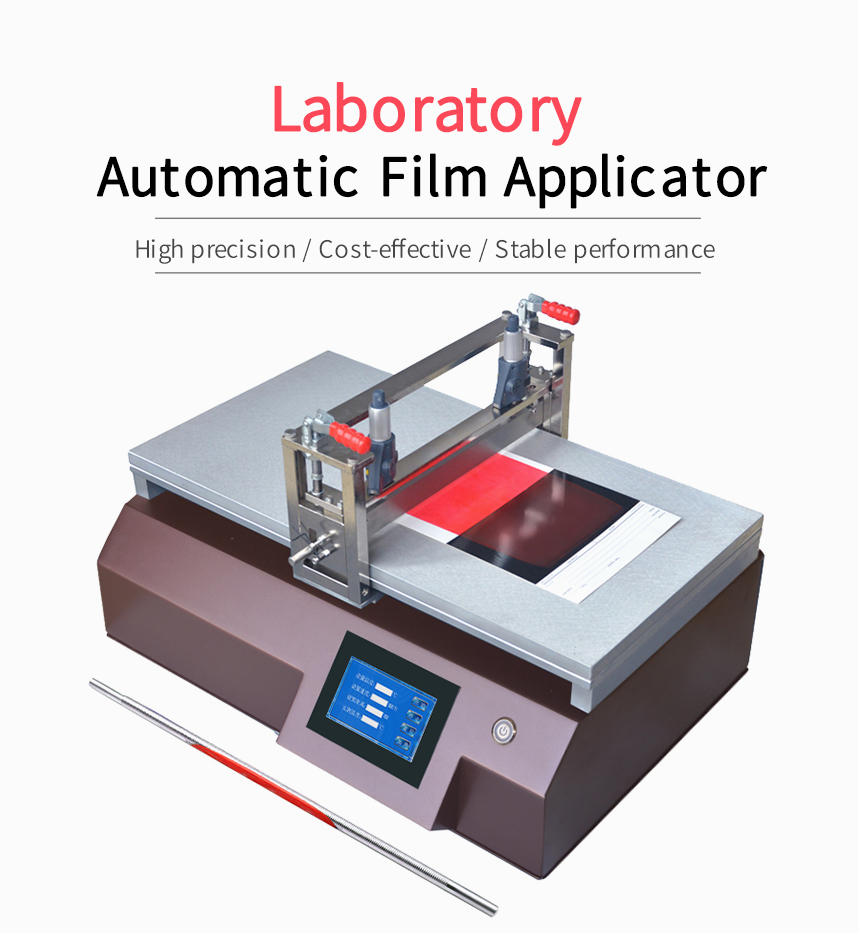

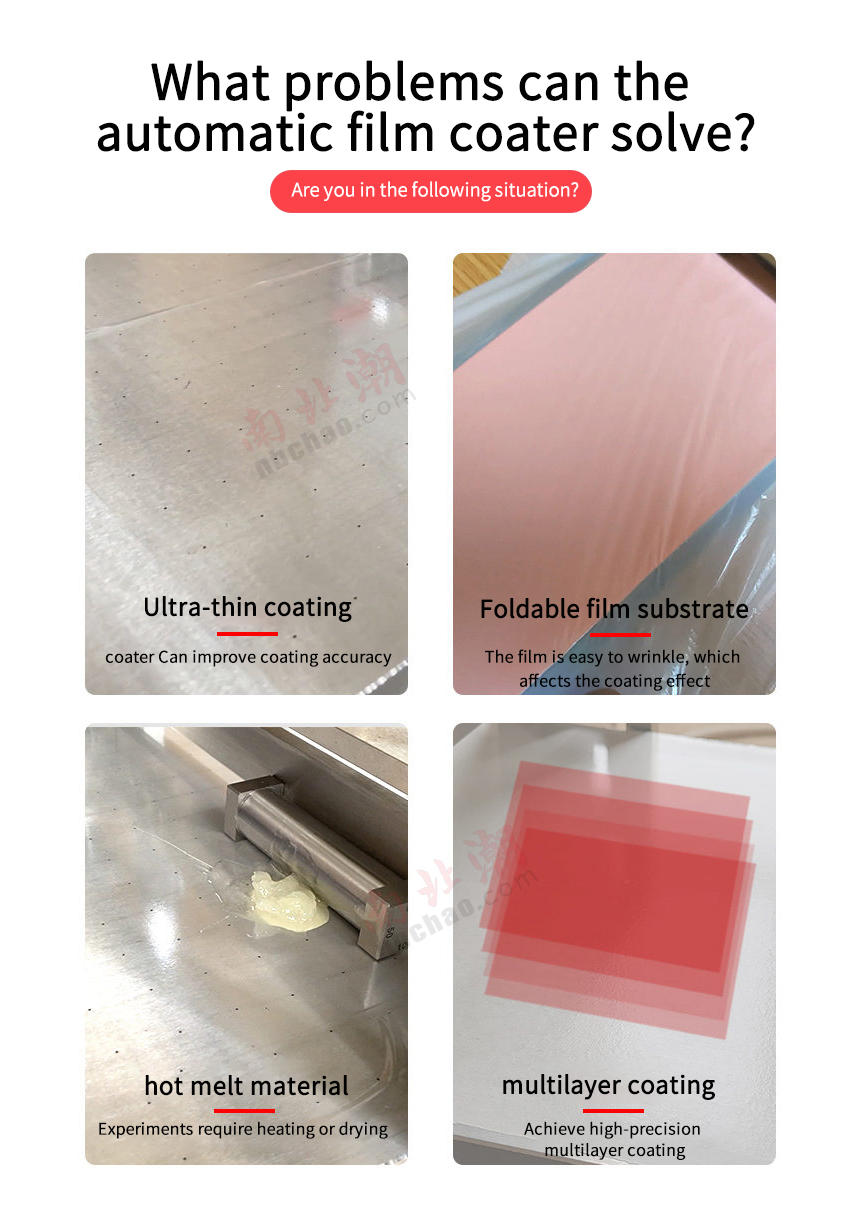

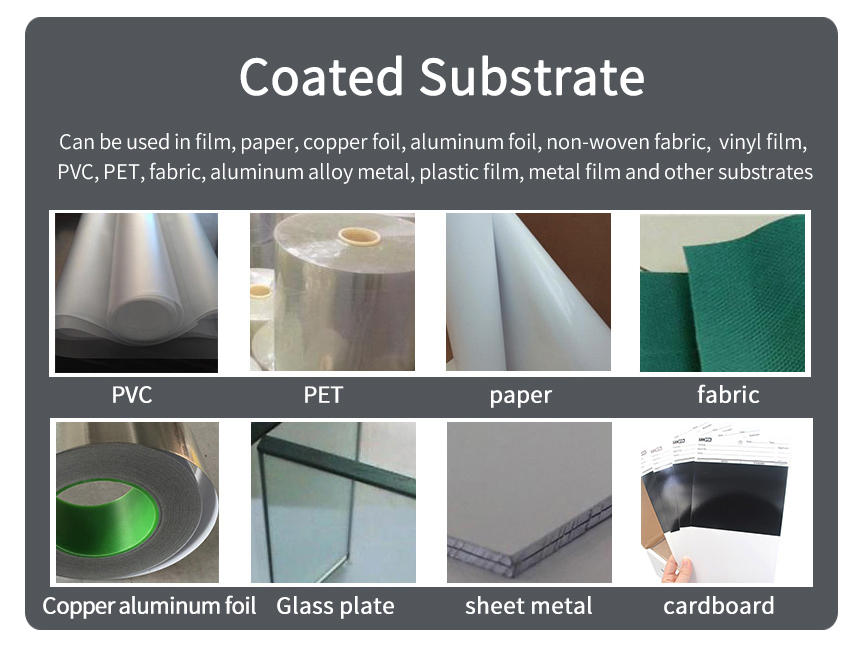

Introduction to automatic film coating machine

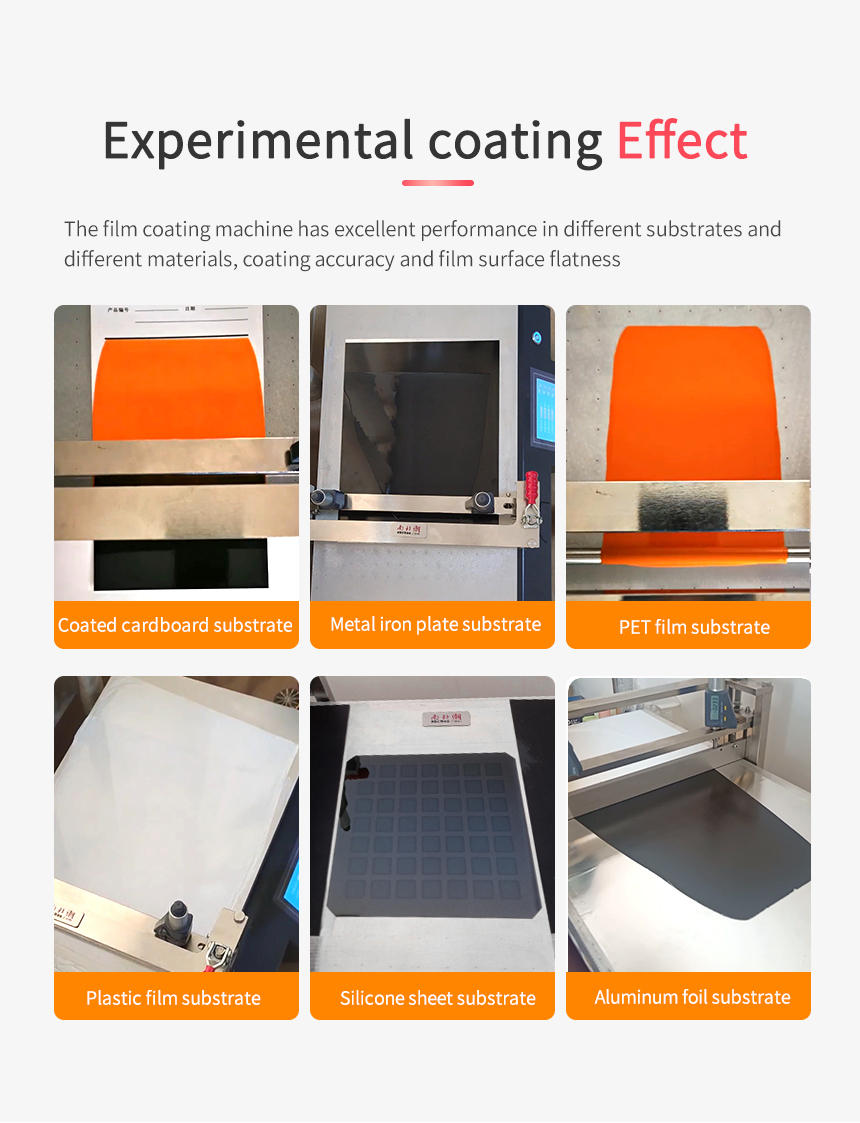

The TBJ-X experimental small coating testing machine all uses imported accessories and is very affordable. It has been favored by many multinational R&D institutions, as well as many well-known universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure, the coating and gluing effect is ensured, and the uniformity and stability of the coating and gluing are ensured.

Since the main factors that affect the coating film are the coating speed and the pressure exerted on the Film Applicator, the coatings applied manually are often inconsistent, especially the differences between different people are even greater. This makes it difficult to compare test results between samples. Our company's automatic Film Applicator is carefully designed to allow operators to easily apply precise wet films on different substrates, greatly improving the reproducibility of coating films.

Application of oven

DHG/type series electric constant temperature Forced Air Drying Oven (hot air sterilization oven) is suitable for industrial and mining enterprises, laboratories, colleges and universities, scientific research units, etc. for drying, baking, melting and wax sterilization.

Oven product features

The box body is welded with high-quality steel plates or stainless steel plates. The working room is made of stainless steel or sprayed with high-temperature resistant silver paint. The four corners of the inner tank are semi-circular arcs, which is convenient for cleaning. The shape is novel, beautiful and energy-saving.

Microcomputer intelligent digital display temperature controller, temperature control is accurate and reliable.

The hot air circulation system uses low-noise fans and suitable air ducts to ensure uniform temperature in the working room.

Optional

- 1Technical Principle and Application Analysis of Silicon Material Automatic Film Applicator

- 2Analysis and application of self-adhesive laboratory coater technology

- 3Application of Experimental Automatic Film Applicator in photoresist film prepative

- 4Three Methods of Preparative Unsupported Adhesive Film on Plastic Plate

- 5Selection Experiment of Small coater in PVC gel membrane prepative

- 6Working principle and application analysis of laboratory oven

- 7Comparison and Difference Between Offset Press and Film Applicator

- 8Principle, application and selection of Electric Oven

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

TBJ-X2+DHG-9070

TBJ-X2+DHG-9070