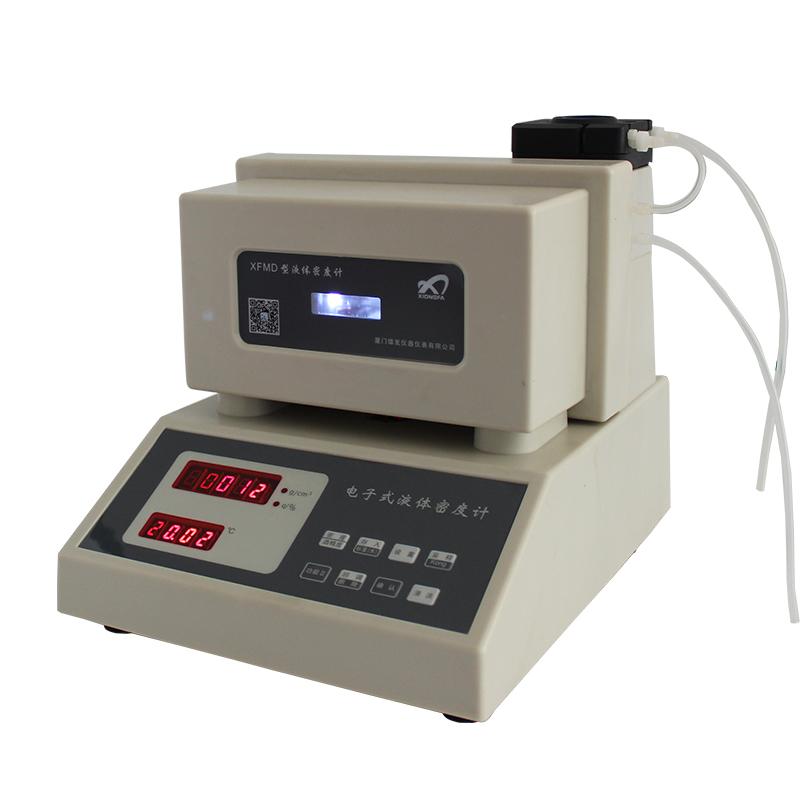

XIONGFA XF-MD100 E-liquid Density Meter U-tube oscillation method Density Meter

SEXIONGFA XF-MD100 E-Liquid Density MeterSPEC

XIONGFA XF-MD100 E-Liquid Density MeterDetails

XIONGFA XF-MD100 E-Liquid Density MeterPacking list

- SKU

- NB037161

- Density Measurement range

- 0.0001 -1.9999g/cm³

- Density resolution

- 0.0001g/cm3

- Automatic temperature control

- 20±0.1℃

- Temperature, repeability

- ±0.1 °C

- U-tube visual function

- Yes

- Automatic sample detection function

- Yes

- Environment temperature requirements

- 5℃~35℃

- Minimum sample dosage approx

- 2 Ml

- Built-in tables and functions

- Density, alcohol concentration table U-shaped tube material

- Weight

- 3.6kg

- Power

- 220V±22V,50Hz±1 Hz,50VA

- Data storage Capacity

- Memory 80 measurement results

- Miscellaneous Special Features

- Built-in Temperature and Humidity Sensors for intelligent environment monitoring

Introduction

U-tube oscillation method density meter, electronic liquid density meter is based on the principle of different oscillation frequencies when the double U-shaped tube is filled with different media to measure the liquid density. After the liquid to be measured is pumped into the sensor of the resonant cylinder, the measurement data is processed by the single-chip microcomputer, which is fast and direct, and has high sensitivity. It is composed of a double tuning fork density sensor, a vibrating cylinder circuit, a temperature measuring circuit, a CPU, a display, a constant temperature tank, a liquid inlet pump and a control panel.

Application

Petroleum, diesel, cleaning fluid, lubricating fluid, chemical fluid, flux, crude oil, chemical reagents, stupid, toluene, flavors and fragrances, essential oils, alcohol, beverages and other industries for density testing, for alcohol and sulfuric acid solutions, can be converted concentration!

Standards

GB/T29617, ISO12185, ASTMD4052/D5002, GB/T29617-2013, GB/T2013-2010, GB23971-2009, GB4747-2009, SH/T0604-2000, SN/T2383-2009, SH/T0729-2004, ASTMD4 052, ASTMD5002, ASTMD1250, ASTMD3505, ISO12185: 1996

features

1. Using the principle of U-tube vibration method, it is suitable for automatic measurement of liquid density

2. Using imported high-speed XFMD chip processing, high sensitivity and accurate data

3. Automatic sampling: adopt Xiongfa special automatic sampling system, automatic quantitative technology, high precision

4. Adopt self-developed residue removal technology to ensure that there is no residue in the sample

5. Constant temperature control: adopt self-developed Peltier refrigeration technology, high cooling efficiency and environmental protection

6. Wall-free treatment: The liquid will leave residual liquid on the inner wall of the oscillation tube during the flow process, which will affect the measurement accuracy. Therefore, by performing wall-free treatment on the inner wall of the oscillation tube, residual liquid on the inner wall of the oscillation tube can be avoided, ensuring The precision of the instrument.

7. Data storage and transmission: built-in memory chip, which can store 80 sets of detection data, and can be recalled and deleted

8. Calibration function: Use pure water at 20°C as the standard to calibrate the instrument, which is a function that cannot be realized by glass density meters.

test steps

Insert the sampling tube into the liquid, press the "sampling" button, the liquid will be automatically pumped into the vibrating cylinder, and when the temperature of the machine reaches 20±0.1°C, the temperature and density of the liquid will be displayed directly on the screen.

automatic cleaning

Drain the liquid in the vibrating cylinder first, and then clean the vibrating cylinder with a suitable cleaning solution until no residue can be seen in the vibrating cylinder.

- 1Color and Gloss Calibration

- 2What is a density meter? How to calibrate?

- 3How does a density meter test the density of a product with a density < 1? [Video explanation]

- 4How does a density meter detect the density of bulk products?

- 5Correct operation steps of liquid density meter [video demonstration]

- 6Densitometer calibration

- 7Application and development trend of defoamer in many fields

- 1GB/T 5526-2024《Animal and vegetable fats and oils—Determination of relative density》

- 2JJF 2094-2021《Measuring Instruments for Density》

- 3GB/T 22627-2022《Water treatment chemicals—Polyaluminium chloride》

- 4GB/T 36650-2018《Inks for optical fiber coloring》

- 5GB/T 2013-2010《Standard test method for density of liquid petrochemical products》

XF-MD100

XF-MD100