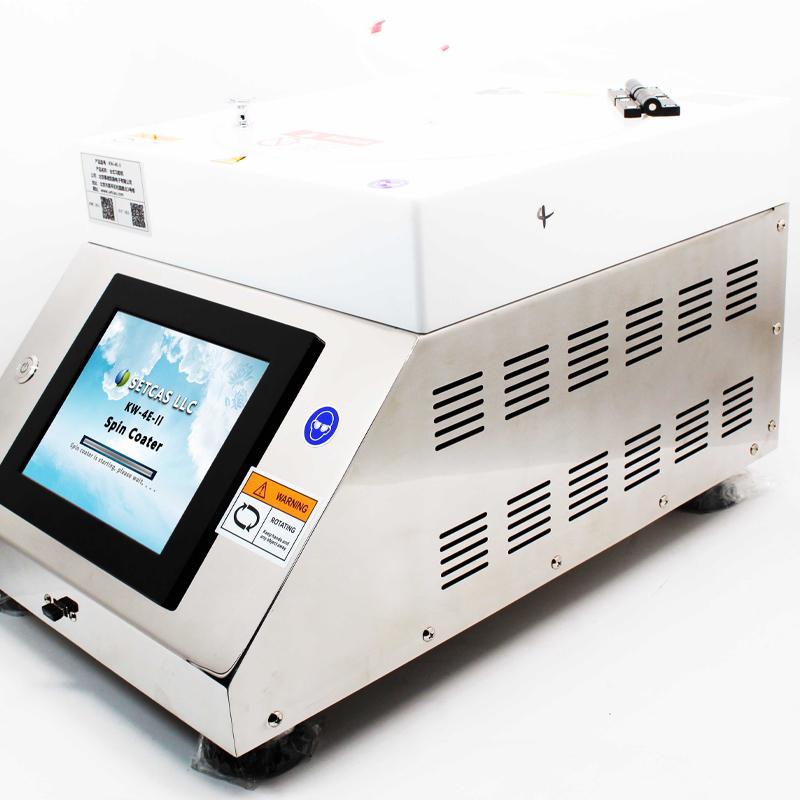

SETCAS setcas KW-4E-II program-controlled Spin Coater, automatic glue drop + remote control

SEMaximum support 8 inches, touch screen with program control, PTFE cavity, with heating temperature control function, remote control function and automatic glue function, maximum Rotation speed 12000rpm.

Price: Please contact customer service

Model:

Setcas KW-4E-II Glue levelerSPEC

Setcas KW-4E-II Glue levelerDetails

Setcas KW-4E-II Glue levelerPacking list

- SKU

- NB038462

- Suitable substrate

- 5~200mm

- Speed range

- 1~12000rpm

- Speed Accuracy

- 1rpm

- Rotation speed stability

- ±0.1%

- Acceleration range

- 1~10000rpm/s

- Swirl/spin direction

- Positive and reverse switching

- glue uniformity

- ±1%

- Heating range

- RT+~200℃

- Heating rate (chamber air temperature)

- To 100 ℃ (1S), to 200 ℃ (2S)

- Chill down

- To room temperature (2S)

- Human Machine Interface

- 8 inch touch screen

- Communication interface

- USB (std.)

- stylus

- BAMBOO Resistance Pen (std.)

- Vacuum pump

- SC-550V oil-free pump

- setup data

- Unlimited sets of data, each set of 15 Rotation speed (std.)

- Programming every time

- 0~10000s

- store data

- Unlimited set of data

- Data Protection

- Default with power failure protection function

- AC Power port of glue leveler

- AC100-250V

- Vacuum pump Power interface

- AC220V (std.)

- Power of glue leveler

- 650W

- Vacuum Pump Power

- 350W

- Pumping Speed

- ≥60L/min

- Volume of homogenizer

- 340*500*250mm

- Gluer Weight

- 18KG

- Pump Weight

- 9KG

- Environmental temperature

- 0~40℃

- Relative Humidity

- <85%

KW-4E-II

Glue leveler

Maximum support 8 inches, touch screen with program control, PTFE cavity, with heating temperature control function, remote control function and automatic glue function, maximum Rotation speed 12000rpm.

Advantages

PTFE polymer chamber material, acid and alkali resistance, corrosion resistance, with a curved chamber bottom to facilitate glue export;

It has the function of exhaust gas pumping and exhausting in the chamber;

Gas heating and drying, temperature range: 0-200°C, heating and cooling speed 100°C/S; forward and reverse spin coating directions can be switched freely;

Real-time display of speed rise curve;

It has the functions of motor glue feeding alarm and protection;

It has alarm and interlock functions for insufficient substrate adsorption force ;

The recipe has a power-down protection function.

Product Structure

KW-4E-II Front Left View Function Introduction

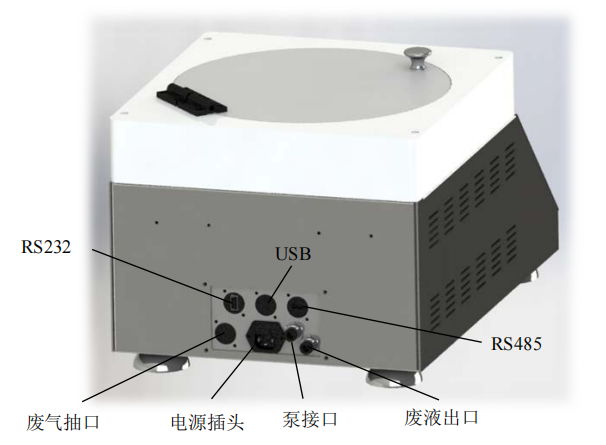

Function introduction of KW-4E-II rear right view angle

KW series homogenizer model comparison

FAQ

QIs the substrate PET trial?

Sheet, a few centimeters to twenty centimeters

A

Horizontal is OK.

QThis spin coating is then heated, which is heating while spinning coating

A

Because ours is controlled by the screen with a program, it can adjust the heating function to a minimum or turn it off. You can spin the coating first and then heat it, or you can spin the coating while heating. There is no problem in both ways.

QThis spin coating is then heated, which is heating while spinning coating

A

Both can be supported.

QIs there any requirement for the outer diameter of the substrate of the homogenizer?

A

The outer diameter of the substrate should be larger than the outer diameter of the chip holder boss by 2 to 4 mm.

QHow often should the air extraction chamber of the glue leveler be cleaned?

A

There are three situations: normal use for three months; Rotation speed of the motor is unstable or stuck; glue is sucked into the exhaust chamber, to be cleaned immediately.

QWhat kind of sheet holder is used for the thickness of the experimental test piece 1mm?

A

0.3~ 2Mm can be selected with suction groove sheet holder, Miscellaneous thickness to be customized sheet holder.

QWhat should I do if the glue is blocked in the small hole of the uniform glue machine?

A

1. Drop alcohol or acetone in the small hole of the tablet holder until it overflows slightly; 2. Soak for about 5 minutes until the alcohol or acetone completely dissolves the photoresist; 3. Open the mechanical pump and open the air supply system until the photoresist and alcohol or acetone are miscible. The solution after acetone is pumped out.

Knowledge

- 1Spin Coater selection and classification: a one-stop guide

- 2Common defects in spin coating of homogenizer

- 3Three small suggestions for improving the effect of spin coating

- 4What are the special requirements for spin-coated nanoparticles?

- 5What are the common problems of spin coating experiment?

- 6Detailed operation steps schematic diagram of the glue leveler

- 7What is spin coating and how does it work?

- 8Common Problems and Maintenance Measures of Spin Coater of Gluer

- 9Spin-on cleaning and specific cleaning steps

- 10Spin coatings spin coaters: principles, applications, functions and maintenance

Standard

KW-4E-II

KW-4E-II