DAQTECH FW-6 Tunnel Temperature Tester 6 Channels -40.0~ 1370.0 ℃

SEDAQTECH FW-6 Tunnel furnace temperature testerSPEC

DAQTECH FW-6 Tunnel furnace temperature testerDetails

DAQTECH FW-6 Tunnel furnace temperature testerPacking list

- SKU

- NB039787

- number of channels

- 6 channel

- Probe type

- K type Thermocouple (optional)

- Temperature measurement range

- -40.0~ 1370.0 ℃ (optional)

- Temperature measurement accuracy

- ±1 ℃

- resolution

- 0.1 ℃

- Storage capacity

- 2008888 data points

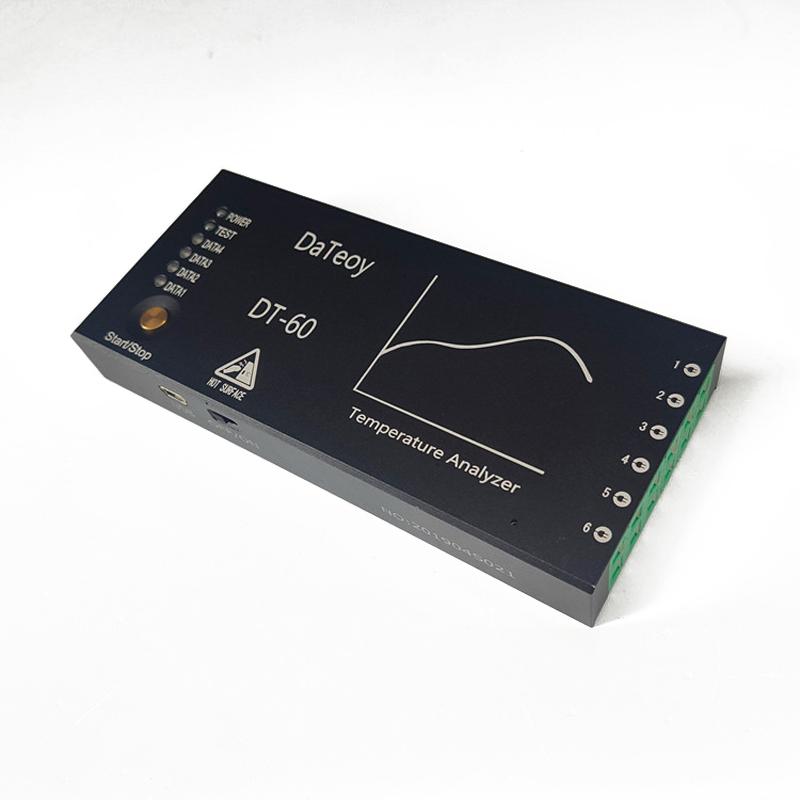

- Recorder size

- 145*60*20 mm

- Heat box size

- Height 16 cm

- Power supply voltage

- DC3.7V~DC4.2V

- connection method

- Wired

- Sampling Frequency

- 0.2~ 200.00 seconds

- data transmission

- Wired transmission/wireless transmission (optional)

- continuous testing

- Can be tested multiple times, storing up to 16 sets of data

- startup mode

- button start, delayed start, temperature start

- Instrument power consumption

- 12mAh

- Instrument temperature resistance

- 80.0 ℃ (Maximum Internal Operating temperature of Recorder)

- Wireless Frequency

- 1.0 to 100.00 seconds (optional)

- stop mode

- Press the button to stop.

- Battery level

- 600mA

- Calibrated mode

- Voltage calibrated, temperature calibrated

- Measurement time

- Hot box temperature resistance 300 ℃ Measurement time 40min

Introduction

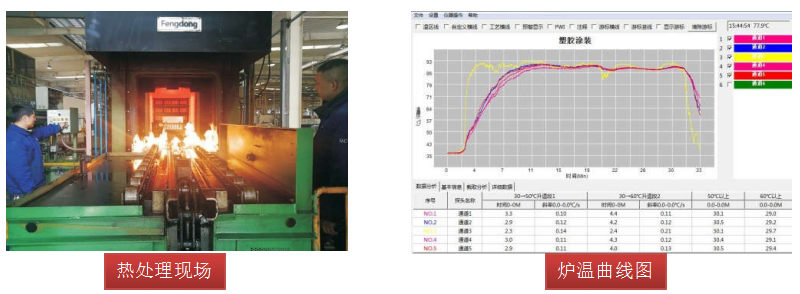

The special temperature measurement system for industrial furnaces is widely used in the coating and heat treatment industries to measure and map the temperature curves of metal products in normalizing furnaces, annealing furnaces, nitriding furnaces, tempering furnaces, and so on. Through this system, users can set and optimize the temperature process, regularly monitor the temperature of metal products and workpieces, and their performance in key high-temperature processes. The key to obtaining good performance of the product in the heat treatment process depends on the process control of the metal heating process. An incorrect time/temperature profile will affect the distribution structure of metal molecules and directly reduce the performance of metal products. With the DaTeoy temperature test system, the process can be monitored without interrupting the normal production process. The Recorder passes through the industrial furnace heating equipment, and can obtain the temperature test curve of up to 16 points on the surface of the workpiece at one time. At the same time, the wireless real-time synchronous data recording function is optional.

Analysis System Advantages

1. Set the temperature and transportation speed of the oven temperature zone

2. The time between any two temperature values

3. The slope between any two temperature values

4. Maximum temperature and arrival time

5. Horizontal temperature line, vertical time line and the time between the two times

6. Test date and time

7. Input of company name, product name and remarks

8. The temperature data report can be exported to Excel for editing

9. Insert picture function to make the position of temperature test point clear at a glance

10. The software clears the memory data of the instrument

11. Three starting modes: manual and specified temperature

Thermometer Advantages

• Up to 8 types of probes to choose from

• Calibrated with standard Voltage and provides cold junction temperature correction

• Real-time wireless/wired data reception (optional)

•Instrument power off, intelligently save data when power off

• Can test multiple times, store up to 16 sets of data

•Using USB communication port, fast download and charging, fully charged and sustainable use for 50 hours

•Various indicator lights indicate various application states of the instrument, one-button operation, easy to learn and use

FW-6

FW-6