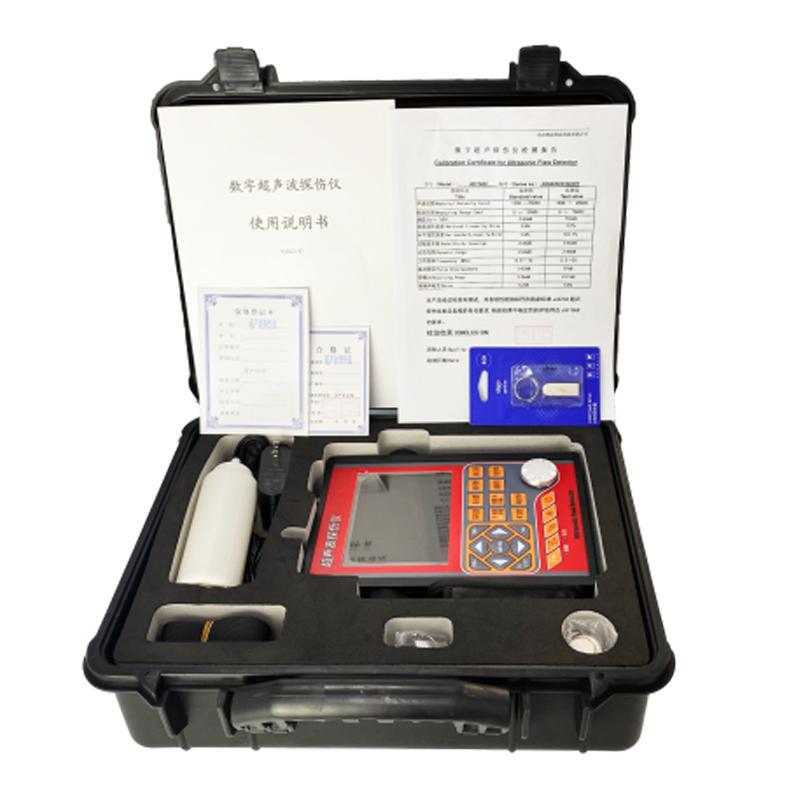

KAIRDA NDT680 digital Ultrasonic Flaw Detector nondestructive detection 500 sets of configuration channels

SEThe 400MHz CPU is used to realize intelligent analysis, and 500 sets of configuration channels meet diverse detection requirements. The high-sensitivity probe can detect extremely small defects, and supports USB2.0 high-speed data transmission.

$1290.00/set

PromotionLoading...

Coupon

Model:

Similar products

KairDa NDT680 Digital Ultrasonic Flaw DetectorSPEC

KairDa NDT680 Digital Ultrasonic Flaw DetectorDetails

KairDa NDT680 Digital Ultrasonic Flaw DetectorPacking list

- SKU

- NB039943

- detection range

- (0~15000)mm

- Frequency

- (0.2~20)MHz

- Speed of sound

- (100~20000)m/s

- Frequency of sexual repeability

- (20~2000)Hz

- Dynamic range

- ≥36dB

- Vertical Linearity

- ≤1.5%

- Horizontal Linearity

- ≤0.1%

- resolution

- >42dB(5P14)

- digital suppression

- (0~80) %, does not affect linearity and gain

- electrical noise level

- ≤10%

- Probe type

- Straight probe, oblique probe, dual crystal probe, penetration probe

- gate

- Inlet gate, loss gate; single gate reading, double gate reading, peak trigger, edge trigger

- Gate alarm

- Beep alarm, LED light alarm

- Power Supply

- Direct current (DC) 9V; lithium battery works continuously for more than 12 hours

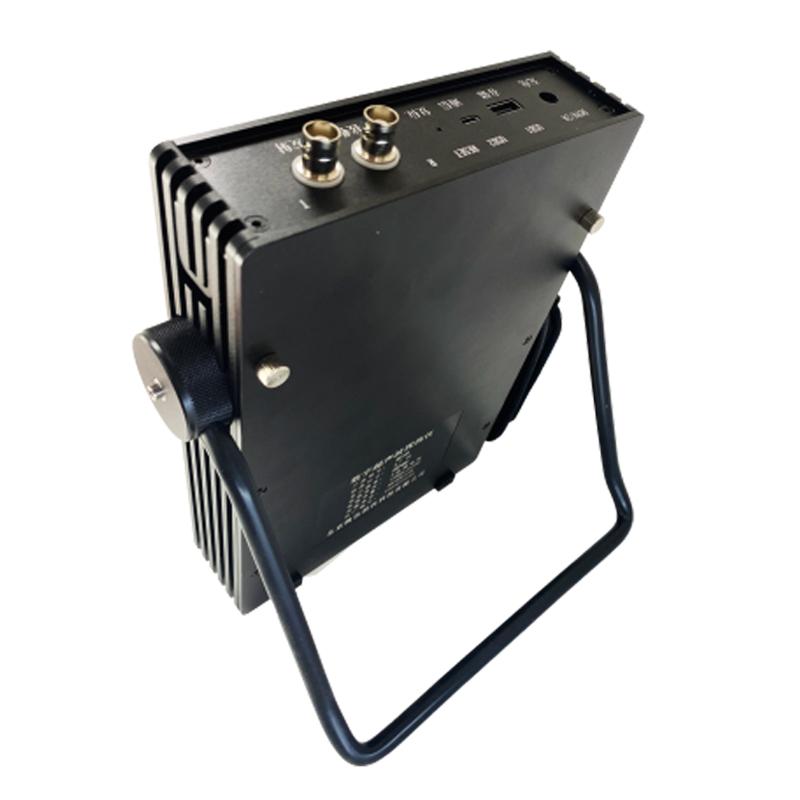

- exterior size

- 263×170×61mm

- Host Weight

- 1.92kg

- Environmental temperature

- (-10~50)℃

- Relative Humidity

- (20~95)%RH

NDT680

Digital Ultrasonic Flaw Detector

The 400MHz CPU is used to realize intelligent analysis, and 500 sets of configuration channels meet diverse detection requirements. The high-sensitivity probe can detect extremely small defects, and supports USB2.0 high-speed data transmission.

FAQ

QWhat is the difference between Magnetic Particle Testing Equipment and ultrasonic flaw detection (UFD)?

A

Magnetic Particle Testing Equipment detects crazing on the surface of the workpiece, only 2-3mm crazing on the surface and near the surface, and ultrasonic flaw detection (UFD) instrument detects internal defects in the work.

Standard

NDT680

NDT680