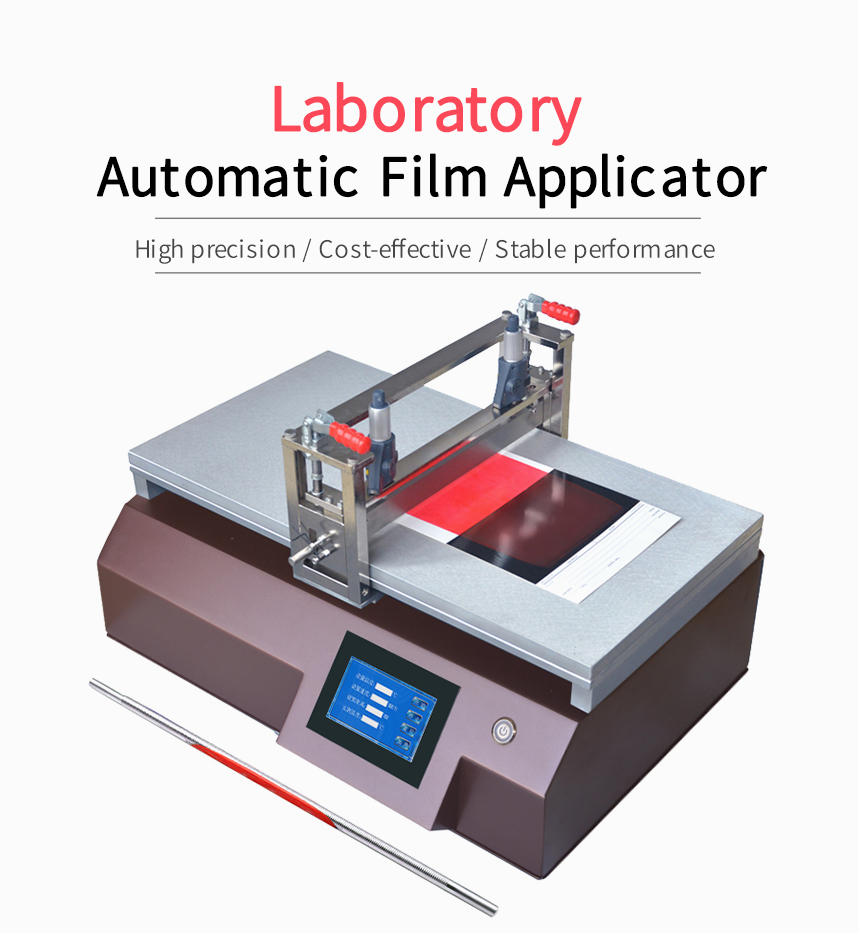

CHINA Perovskite Special Film Applicator with Imported Wire Bar + Jeaner Applicator

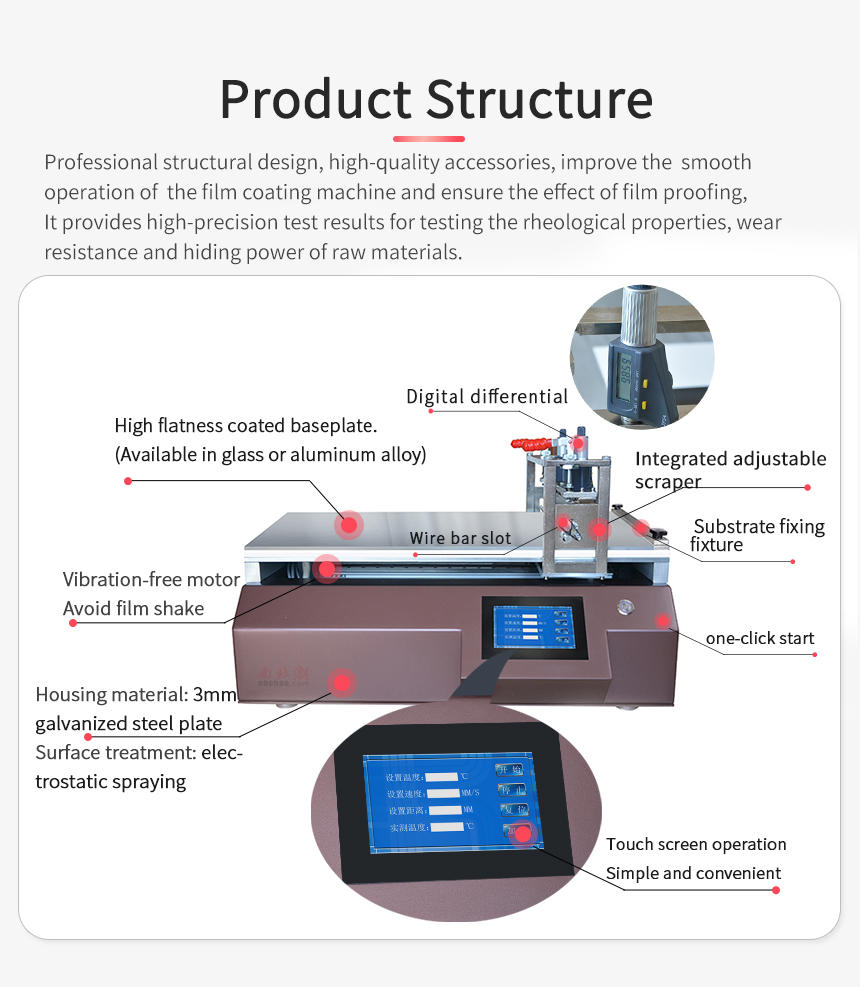

zy TBJ-X4-ABO Automatic Film ApplicatorSPEC

zy TBJ-X4-ABO Automatic Film ApplicatorDetails

zy TBJ-X4-ABO Automatic Film ApplicatorPacking list

- SKU

- NB040231

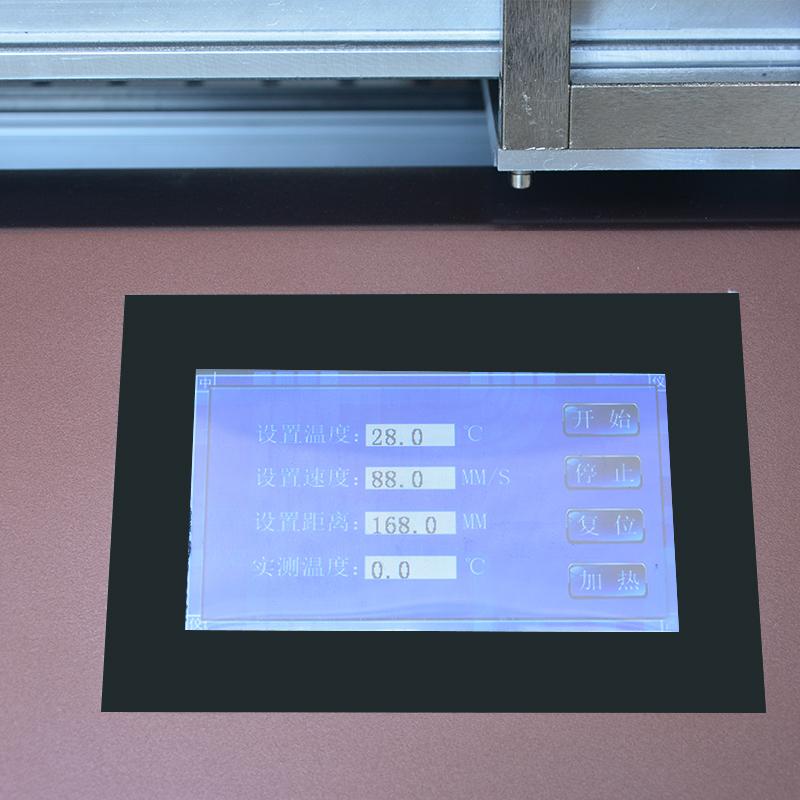

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

- Coating size

- 300*400mm

- Spreader speed

- Digital display, different speeds

- Vacuum Area

- 300 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Film applicator

- 1 Imported Wire Bar and Jenner Film Applicator

- Host Power

- 220V 50Hz

- Dimensions

- 630*410*520mm

- Weight

- 65kg

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- Heating temperature range

- RT+~200℃

- Temperature Uniformity

- ±3℃

- Power

- 1500W

- Vacuum pump size

- 380*180*280mm

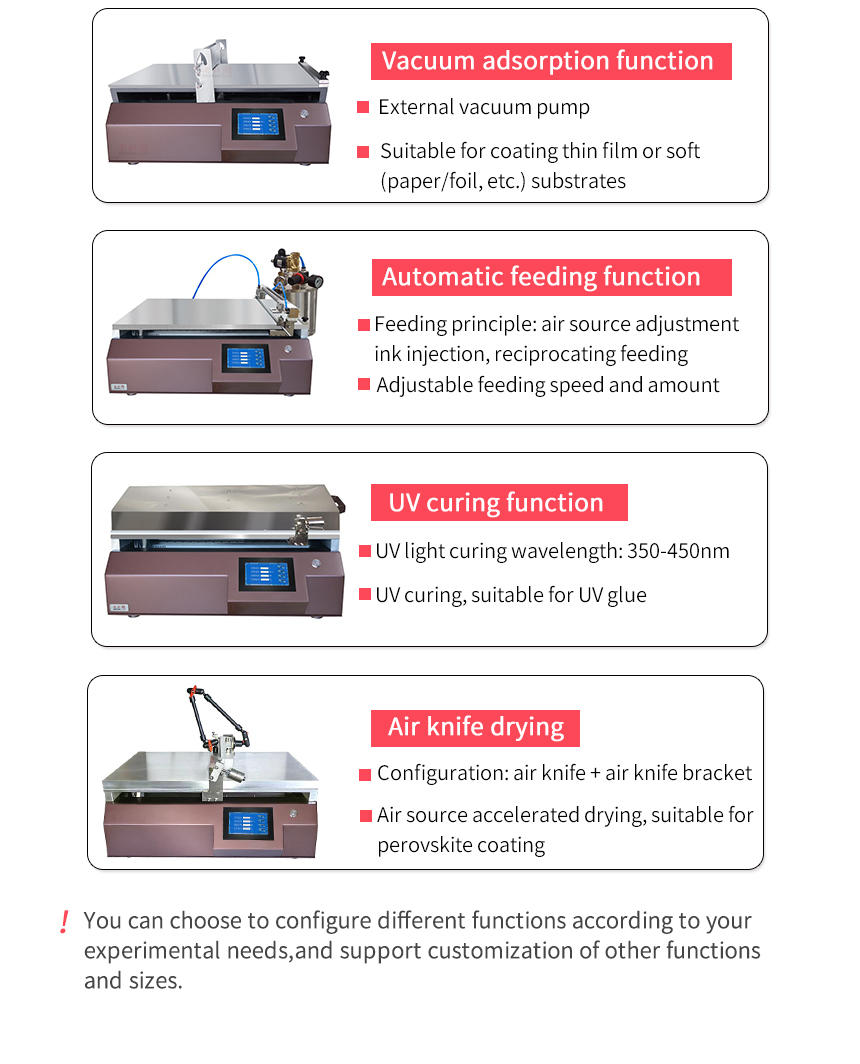

- Optional

- Leakage tank, substrate fixing fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

- Customizable function

- Jet system device, UV solid-containing device, automatic inking system

- Standard configuration

- Air knife + air knife bracket

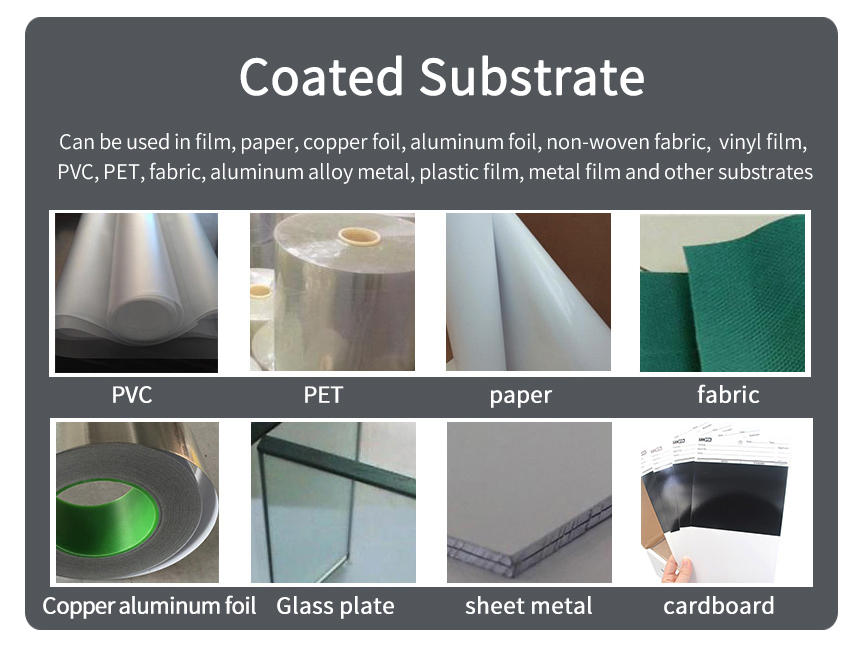

product description

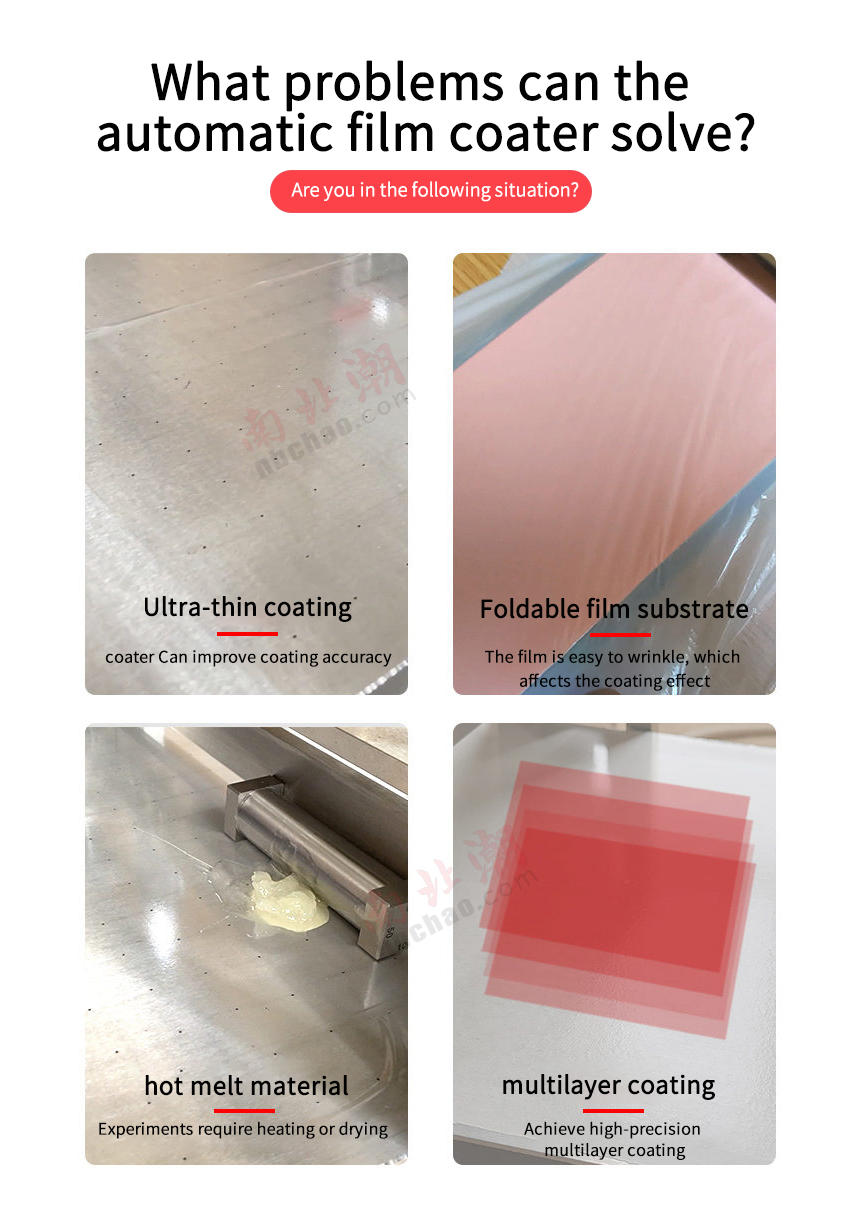

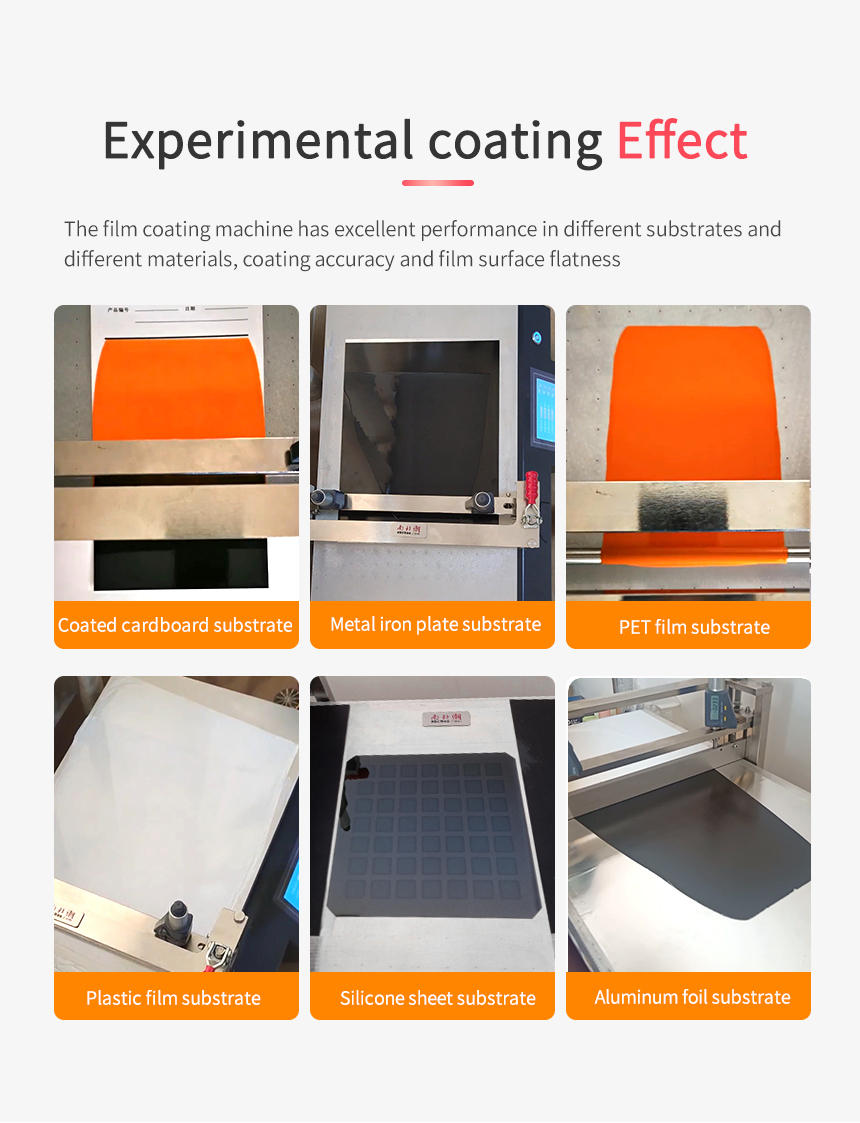

The perovskite-specific coating machine is equipped with imported high-precision coating equipment, including imported wire rods and Jayener Wet Film Applicators. It has heating and vacuum adsorption functions. It is equipped with an air knife and an air knife holder, and uses nitrogen as the gas source to add calcium. The titanium ore solution is dried.

With the emergence of the film coating machine, the main factors that affect the coating film are the coating speed and the pressure exerted on the Film Applicator. Therefore, the coatings applied manually are often inconsistent, especially the differences between different people. This makes it difficult to compare test results between samples. The automatic film coating machine is carefully designed to allow operators to easily apply precise wet films on different substrates, greatly improving the reproducibility of coating films.

Optional

- 1Advantages of drawdown blade method in preparation of perovskite solar cells

- 2What is a perovskite material?

张勇 - 《武汉理工大学》

- 3Preparation process of perovskite thin films

丁相宇 - 《长春理工大学》

- 4What is groove die coating?

- 5Application of Coating Machine in Perovskite Coating

- 6What are the functions of Perovskite Film Applicators?

- 7Perovskite Spreader Technology: Preparative Efficient Solar Cell Thin Film

- 8Application and Advantages of Coater in Antipyretic Sticker prepative

- 9Application and optimization of Automatic Film Applicator in preparation of eye patch

- 10Perovskite solar cell preparatory method using solvent immersion resistant applicator

TBJ-X4-ABO

TBJ-X4-ABO