HUDA rain Test Chamber QD-E710-IPX3456-225

SEHUDA QD-E710-IPX3456-225 Rain Test ChamberSPEC

HUDA QD-E710-IPX3456-225 Rain Test ChamberDetails

HUDA QD-E710-IPX3456-225 Rain Test ChamberPacking list

- SKU

- NB041445

- Inner box size

- 500*600*750mm

- Sample size

- 350X350mm

- Turntable diameter

- 600mm

- Power

- 380V / 12KW

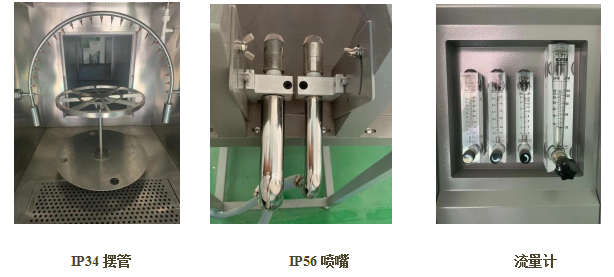

- IPX34-pendulum tube

- Radius 400mm, (standard) Miscellaneous size can also be customized

- IPX34-Inner diameter of pendulum tube

- ¢16mm

- IPX34-Nozzle inner hole

- 0.4mm

- IPX34-Spray hole distance

- 50mm

- IPX34-pendulum tube material

- 304 stainless steel industrial pipe

- IPX34-Nozzle Angle

- IPX3: 120 °, IPX4: 180 °

- IPX34-pendulum tube angle

- IPX3:120 °, IPX4:320 ° (approximate)

- IPX34-Spray Pipe Swing Speed

- IPX3 15 times/min; IPX4 5 times/min about 2X360 degrees/12 S

- IPX34 - rain water pressure

- 80 ping 150Kpa

- IPX34 - Flow rate

- R400 pendulum tube: 1.75L/M

- IPX34 - Flow rate calculation

- Number of nozzle holes X0.07L/M = Flow rate of the water outlet of the pendulum pipe, the flow rate of the water spray can be set

- IPX56-Spray System

- 1 IPX5 nozzle, 1 IP6 nozzle

- IPX56-Nozzle Aperture

- IPx5: ¢6.3mm, IPx6: ¢12.5mm

- IPX56-Nozzle Connectivity

- Threaded connection, looper connection with water pipe, simple and convenient operation

- IPX56 - Flow rate

- IPX5: 12.5L / M ± 0.625L, IPX6: 100L / M ± 5L

- IPX56 - Injection time

- Universal standard 3 minutes, or more time can be set

- IPX56-Injection distance

- The sample is 2.5-3 meters away from the nozzle, and the distance is controlled by the Tester

- IPX56-Nozzle Connection Hose

- Inlet transparent hose with stainless steel wire

- IPX56-Nozzle Material

- 304 stainless steel

Equipment use

The main function of the equipment is to test the performance of the equipment during storage, transportation and use in the rainy climate environment. Components and other equipment are tested on the physical and other related properties of the equipment under simulated rainy weather conditions. After the test, the performance of the equipment is judged to meet the requirements through verification, so as to facilitate the design, improvement, verification and factory inspection of the equipment. .

Executive standard

GB2423,38-90, GB4706.32-2004 IEC-529

test method

1. IPX3 test method

Sample placement: Select a swing tube with an appropriate radius so that the height of the sample table is equal to the diameter of the swing tube, place the sample on the sample table so that the distance from the top to the sample water nozzle is not more than 200mm, and the sample table does not rotate.

Test conditions: The water flow rate is calculated according to the water spray rate of the pendulum pipe, and each time is 0.07L/min. When spraying water, spray water from the water spray holes in the 60° arcs on both sides of the midpoint of the swing pipe to the sample. The sample to be tested is placed in the center of the semicircle of the swing tube. The swing tube swings 60° on both sides of the vertical line, a total of 120°. Each swing (2×120°) is about 4s.

Test pressure: 80-150kPa

Test time: Continuous watering for 10 minutes; sample rotates 90° after 5 minutes of test

2. IPX4 test method

Sample placement: Select a swing tube with an appropriate radius so that the height of the sample table is at the diameter of the swing tube, place the sample on the sample table so that the distance from the top to the sample water nozzle is not more than 200mm, and the sample table does not rotate.

Test conditions: The water flow rate is calculated according to the number of spray holes of the swing pipe, and each hole is 0.07±0.5L/min. The water spraying area is the water spraying holes in the 90° arcs on both sides of the midpoint of the pendulum pipe to the samples. The sample to be tested is placed in the center of the semicircle of the swing tube. The swing tube swings 180° on both sides of the vertical line, about 360° in total. Each swing (2×360°) is about 12s. Test pressure: 80-150kPa

Test time: Spray water continuously for 10 minutes and rotate the sample 90° after 5 minutes of test

QD-E710-IPX3456-225

QD-E710-IPX3456-225