Hypertherm HVA-P hand disk microHardness Gauge 0-3000HV

SEHBO HVA-P MicroHardness GaugeSPEC

HBO HVA-P MicroHardness GaugeDetails

HBO HVA-P MicroHardness GaugePacking list

- SKU

- NB042155

- Measurement unit

- 0.25μm

- test force

- 10gf (0.098N)、25gf (0.245N)、50gf (0.49N)、100gf (0.98N )、200gf (1.96N)、300gf (2.94N)、500gf (4.9N)、1000gf (9.8N)

- Measurement range

- 0-3000HV

- Measurement Accuracy

- Suitable for or higher than GB/T4340.2

- Total Magnification

- 100X (observation,) 400X (measurement)

- loading method

- Automatic (loading, retaining, unloading)

- Data output

- LCD display readout

- Load time

- Adjustable in 5-60 seconds

- instrument size

- 405×290×480mm

- instrument Weight

- About 35Kg

- Maximum height of specimen

- 90mm

- Distance from the center of the indenter to the inner wall

- 120mm

- Conversion ruler

- HRA、HRB、HRC、HRD、HRE、HRG、HRF、HRK、HV、HK、HBS、HR15N、HR30N、HR45N、HR15T、HR30T、HR45T

- Power Supply

- AC220V±5%,50~60Hz

- execution standard

- GB/T4340.1, GB/T4340.2, IS06507-2, ASTM_E384 JJG151 verification procedures

- X-Y Test Bench

- Size: 100 × 100 mm, Maximum movement: 25 × 25mm, Minimum displacement: 0.01mm

- Accessories

- CCD camera measurement system, Knoop indenter, filament clamping table

Introduction

It adopts LCD display, can switch the hardness scale Vickers (HV) and Knoop (HK), easy to operate, high-definition optical system, light source brightness can be adjusted in 20 levels, multiple hardness system conversion functions, use micrometer eyepiece to measure the diagonal Line length D1 and D2 values, the hardness value can be displayed on the LCD after key input. Integrated cast aluminum body, no deformation or displacement, weight loading structure, stable performance, high measurement accuracy and good repeatability.

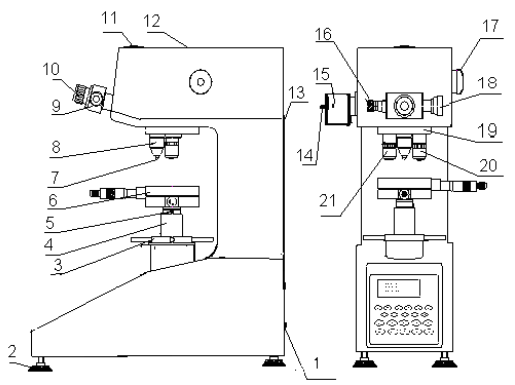

product structure

1. Power plug, 2. Horizontal screw, 3. Lifting wheel, 4. Lifting screw, 5. Screw, 6. Cross test stand, 7. Indenter, 8. Protective cover, 9. Micrometer eyepiece, 10. Eye mask

11. Photography interface, 12. Upper cover, 13. Back cover, 14. Up and down adjustment nut of the light source, 15. Front and rear adjustment screw of the light source, 16. Left drum, 17. Change handwheel, 18. Right drum

19. Turret, 20.40Ñ objective lens, 21.10X objective lens

Introduction to panel key functions

The main function

â Adopt LCD display, switchable between Vickers (HV) and Knoop (HK) hardness scale;

âEasy to operate;

â The brightness of the light source of the high-definition optical system can be adjusted in 20 levels;

â Multiple hardness system conversion functions;

â Use the micrometer eyepiece to measure the diagonal length D1 and D2 values, and the hardness value can be displayed on the LCD after key input;

â Accurate positioning.

Application scope

Suitable for testing metal structures, metallography and metallography research, including tiny parts, thin plates, metal foils, wires, thin hardened layers and electroplated surface coatings, quenched hardened layers, nitride layers, steel, non-ferrous metals, ceramics, alloys , heat treatment, carbonization, ultra-small and relatively thin parts with thickness as thin as 3μm, hardened layer depth measurement, etc.

Standards compliant

GB/T4340.1-1999 GB/T 4340.1-1999 Metal Vickers hardness test Part 1: Test method

GB/T4340.2-1999 GB/T 4340.2-1999 Metal Vickers hardness test Part 2: Inspection of Hardness Tester

ISO 6507-2:2018 "Vickers Hardness Test of Metallic Materials Part 2: Inspection and Calibration of Hardness Testers" International Standard

ASTM E384-17 Standard Test Method for Knoop and Vickers Hardness of Materials

JJG151 - Calibration regulations for metal Vickers Hardness Tester

HVA-P

HVA-P