TAISITE 202-3AB desktop electric thermostatic Drying Oven program temperature control 250 ℃/225L

-

Kenton KH-75A laboratory electric air blowing dryer 225L with independent temperature limiter$ 538.00SE

Kenton KH-75A laboratory electric air blowing dryer 225L with independent temperature limiter$ 538.00SE -

Kenton KH-75AS digital electric air blowing dryer 250 ℃/225L with independent temperature limiter$ 749.00SE

Kenton KH-75AS digital electric air blowing dryer 250 ℃/225L with independent temperature limiter$ 749.00SE -

Kenton KH-75T digital electric air blowing dryer 250 ℃/228L with independent temperature limiter$ 1360.00SE

Kenton KH-75T digital electric air blowing dryer 250 ℃/228L with independent temperature limiter$ 1360.00SE

TaiSiTe 202-3AB (with program mode) Electric thermostatic Drying OvenSPEC

TaiSiTe 202-3AB (with program mode) Electric thermostatic Drying OvenDetails

TaiSiTe 202-3AB (with program mode) Electric thermostatic Drying OvenPacking list

- SKU

- NB043098

- Convection mode

- Natural convection

- Temperature range

- RT+10~250°C

- Temperature Resolution

- 0.1℃

- Temperature Fluctuation

- ±1.0℃

- Temperature Uniformity

- ±3.5%

- Chamber material

- stainless steel plate

- Enclosure Material

- Cold rolled steel plate, surface resistance painting

- Thermal insulation material

- aluminum silicate fiber

- Heating mode

- Nickel-chromium alloy heating wire OCr27A17Mo2

- Input Power

- 4Kw

- Exhaust port

- Inner diameter 28mm * 2, rear; overhead test hole

- thermostat

- Digital tube dual row PID

- Temperature setting

- Tap the four-button settings

- Temperature representation

- Measuring temperature display: 4-digit digital upper display; setting temperature display: 4-digit digital lower display

- Timer

- 0~9999Min (with Timer waiting)

- Run function

- Fixed value operation, Timer operation, automatic stop

- Program Mode

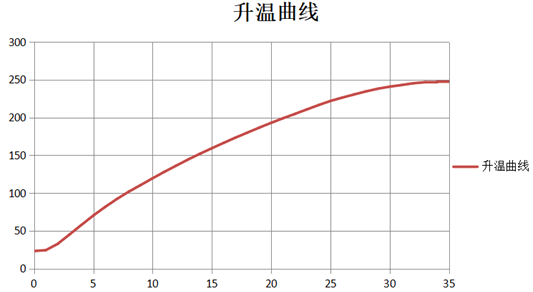

- Standard, single-stage temperature control and program temperature control can be converted to each other, 50 experimental programs can be stored, each program can be set to 50 steps, and each step can be set to 0-6000 minutes adjustable

- Additional features

- Deviation correction, menu button lock, power outage compensation, power outage memory

- Temperature sensor

- pt100

- Safety Devices

- Overrise alarm

- Interior size

- 600*500*750mm

- Dimensions

- 860*623*985mm

- Packing size

- 1020*804*1102mm

- Volume

- 225L

- Load per shelf

- 15kg

- Shelf (std.)

- 21pcs

- Shelf spacing

- 25mm

- Power

- AC220V/18.2A 50/60Hz rated current

- Net Weight

- 77kg

- Gross Weight

- 95Kg

- Shelf (std.)

- 2pcs

- Shelf (std.)

- 4pcs

Features

1. The shell is formed by good cold-rolled steel plateThe surface is treated by a spraying process and used in the studioStainless steel or cold-rolled steel plate is processed and formed, and it is guardedRotting process treatment

2. The intelligent thermostat adopts P|D control programDual digital display, with timing function, accurate temperature controlTrue.

3. The middle of the door is equipped with double-layer tempered glass for observationwindow, which allows you to observe the heated items in the studio at any timesituation

4. The door is sealed with silicone rubber strips, and the sealing effect is good.

Classic natural convection drying.

Convenient operation, fixed value operation, timed operation, automatic stop.

Dedicated function keys enable temperature setting.

Auxiliary menu, realize over-rise alarm, deviation correction, menu locking.

Security –Over-lift alarm, menu lock.

apply

For drying, baking, and heat treatment

Serial models

| Model | Rated power | Content volume | Number of partition layers |

| 202-0A/AB | 1.2KW | 43L | 9 floors |

| 202-1A/AB | 1.6KW | 71L | 13 floors |

| 202-2A/AB | 2.0KW | 136L | 17 floors |

| 202-3A/AB | 4KW | 225L | 21 floors |

| Other parameters | |||

| manner | Natural convection | ||

| Operating temperature range | RT+10~250℃ | ||

| Temperature resolution | 0.1℃ | ||

| Temperature fluctuations | ±1.0℃ | ||

| Temperature distribution accuracy | ±3.5% | ||

| Built-in | B: Stainless steel plate None B: High-strength carbon steel plate | ||

| Exterior | Cold-rolled steel plate, surface resistant coating | ||

| Insulating materials | Aluminum silicate fiber | ||

| heater | Nichrome heating wire OCr27A17Mo2 | ||

| Exhaust outlets | Inner diameter 28mm*2, rear, overhead test hole | ||

| Temperature control method | Digital tube double row PID | ||

| Temperature setting method | Tap the four buttons to set it | ||

| Temperature representation | Measured temperature display: 4-digit digital upper display, set temperature display: 4-digit digital lower display | ||

| timer | 0~9999 minutes (with timed waiting function) | ||

| Run the function | Fixed-value operation, timed operation, automatic stop | ||

| Program mode | Standard, single-stage temperature control and program temperature control can be converted to each other, 50 experimental programs can be stored, each program can be set to 50 steps, each step can be set 0-6000 minutes can be adjusted | ||

| Additional features | Deviation correction, menu key locking, power failure compensation, power failure memory | ||

| sensor | pt100 | ||

| Safety devices | Overlift alarm | ||

| power supply | AC 220V | ||

| clapboard | 2 pcs | ||

| Partition shelves | 4 pcs | ||

| Configurations can be added | Partition, RS485 interface, printer, Recorder, external communication, remote control, program thermometer, wireless SMS alarm, U disk data storage | ||

202-3AB (with program mode)

202-3AB (with program mode)