LEEB BTQGS600 Wire Rope Flaw Detector Diameter range φ 1.5~ 300mm Measurement report

Leeb BTQGS600 Wire rope Flaw DetectorSPEC

Leeb BTQGS600 Wire rope Flaw DetectorDetails

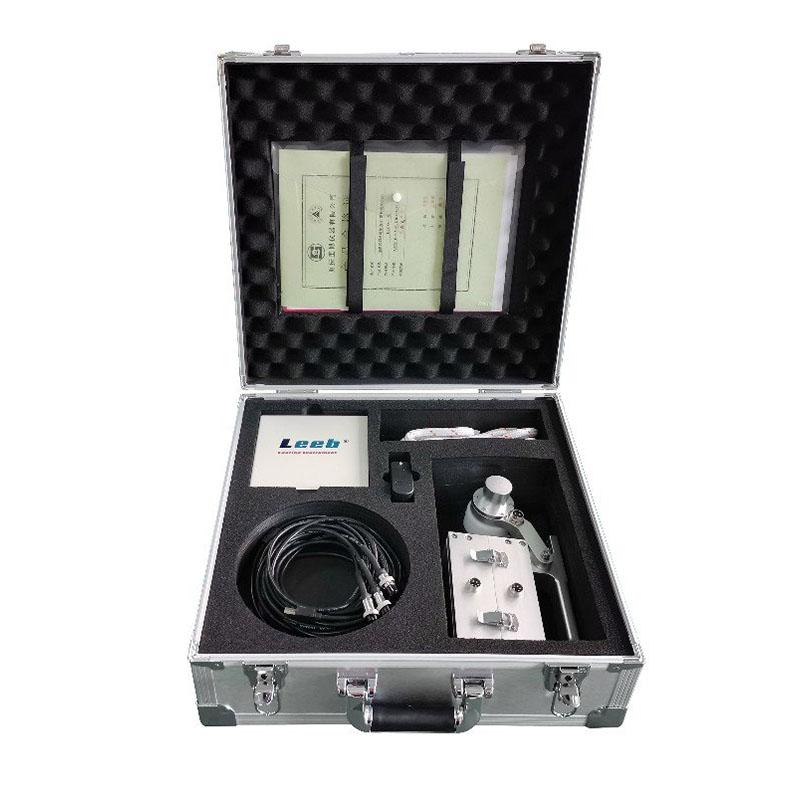

Leeb BTQGS600 Wire rope Flaw DetectorPacking list

- SKU

- NB043829

- Detection wire rope diameter range

- Φ1.5~ 300mm (Sensors of different series specifications need to be configured)

- Sensors relative speed to wire rope

- 0.0~6.0 m/s;建议:0.3~1.5m/s

- Sensors guide sleeve and wire rope clearance

- Recommended 2~ 6mm, allowable clearance: 0~15mm

- Qualitative detection capability of broken wire defect (LF)

- The Accuracy rate of qualitative detection of single centralized broken wire is 99.99%

- Quantitative detection capability of broken wire defect (LF)

- The number of broken wires in a single place allows one or one equivalent root to be misjudged

- The Accuracy of quantitative detection of more than 100 times without error in the number of broken wires in a single place

- Accuracy ≥ 95%

- Detection sensitivity Repeatability allowable error

- ±0.055%

- Detection Accuracy indication allowable error

- ±0.2%

- Position (L) detection capability

- Detection length indication percentage error: +/- 0.2%

- Power

- Computer battery powered 5V

- Sensors Weight

- Common specification < 10kg

- Ambient Temperature

- -10℃~40℃

- Atmospheric pressure

- 86~106Kpa

- Relative Humidity

- ≤85%

- Accessories

- Diameter above 58mm is optional for customized Sensors; computer

Overview

It can detect various defects such as broken wire, wear, rust, deformation, loose strands, skipping wire, material change and other defects in the wire rope online.

The test result report can meet the standards of different industries, and at the same time has the number of broken wires and the ratio of broken wire area to the total cross-sectional area of steel wire.

The computer USB interface is used to directly sample, process and analyze, and has the functions of online sound and light alarm and real-time display of results.

The circular structure of the sensor, circumferential surrounding, and axial magnetization instantly magnetize the wire rope to a saturated state.

The sensor is made of alloy aluminum shell, which has the functions of waterproof, dustproof, shockproof and moisture-proof.

Stable work, reliable performance, high detection accuracy, strong anti-interference performance, accurate data.

The software adapts to various computer operating systems such as Windows 98/2000/XP/Vista/Windows 7

According to the provisions of the National Metrology Law and the National Safety Production Law, each instrument is inspected by the national metrology agency as a third party according to the United States ASTM1571 American standards, and a test report is issued to obtain legal qualifications.

It is widely used in mines, ropeways, lifting equipment, elevators, port machinery, cable bridges and other fields.

Technical core and legal qualifications

1. Virtual Instruments: Wire ropes are infinitely uncertain. Only by applying virtual instrument technology, replacing traditional instruments with software, and directly sampling and processing by the computer, can we ensure that there is no missed detection and no misjudgment, just like watching a movie, the wire rope is scanned throughout the process, and the results are accurate and repeatable.

2. Sanding Instrument: According to the national standards for the scrapping of wire ropes in different industries, this product applies electromagnetic qualitative, quantitative and positioning, and online non-destructive detection of internal and external wire rope breakage, rust, wear, metal cross-sectional area change, loose strands, wire jumping, deformation, material abnormalities and other defects.

3. This instrument meets the following standards:

GB/T 26832-2011 Technical conditions for non-destructive testing instruments and wire rope electromagnetic Detectors

American Standard ASTM1571-2006

- 1The working principle and application of eddy current Flaw Detector

- 2Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

BTQGS600

BTQGS600