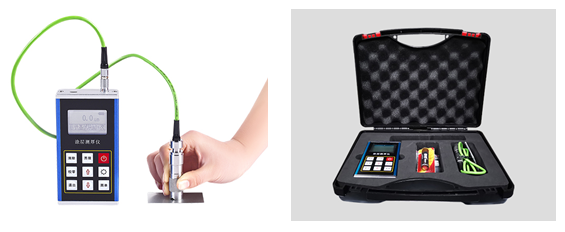

LEEB Leeb231 eddy Current Coating Thickness Gauge Measurement range 0~1250μm

-

LEEB261 high-precision Coating Thickness Gauge eddy Current

LEEB261 high-precision Coating Thickness Gauge eddy Current -

KAIRDA NDT530 (N1) Zinc Coating Thickness Gauge with eddy Current Probe$ 287.00SE

KAIRDA NDT530 (N1) Zinc Coating Thickness Gauge with eddy Current Probe$ 287.00SE -

Leeb242 (N1) Coating Thickness Gauge can print measurement data

Leeb242 (N1) Coating Thickness Gauge can print measurement data -

LEEB211 coating Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields

LEEB211 coating Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields -

Leeb221 Coating Thickness Gauge to detect the thickness of non-conductive coated Films on non-metallic substrates

Leeb221 Coating Thickness Gauge to detect the thickness of non-conductive coated Films on non-metallic substrates

Leeb Leeb231 Coating Thickness GaugeSPEC

Leeb Leeb231 Coating Thickness GaugeDetails

Leeb Leeb231 Coating Thickness GaugePacking list

- SKU

- NB043852

- Probe type

- N1

- Measurement principle

- Eddy Current

- Measurement range

- 0~1250μm

- Low resolution

- 0.1μm

- An indication of calibrating error

- ±(3%H+1)

- An indication of two-point calibrating error

- ±[(1~3%)H+1]

- Minimum radius of curvature

- Convex 1.5mm, Concave 9mm

- minimum area diameter

- Φ7mm

- Basic critical thickness

- 0.5mm

- temperature

- 0~40℃

- Humidity

- 20%~90%

- Power Supply

- AA type alkaline battery 1.5V two

- Dimensions

- 130 * 70 * 25Mm (host)

- Weight

- 350g

- Shell material

- Metal shell

- optional

- Standard test piece, probe, pc communication

Overview

The eddy current measurement method enables non-destructive detection of the thickness of non-conductive insulating overlays on non-magnetic metal substrates (e.g. rubber, plastics, paints, oxide films, etc.) on non-magnetic metal substrates.

This instrument can be used in electroplating, anti-corrosion, chemical industry, automobile, shipbuilding, light industry, commodity inspection and other testing fields. It can be used both in the laboratory and in the engineering field. It is an important instrument in the inspection industry.

Features

● There are two measurement methods: continuous measurement and single measurement;

● It has two Operating Modes: direct and group;

● It has automatic statistical functions: average value (MEAN), maximum value (MAX), minimum value (MIN), number of tests (NO.), standard deviation (S.DEV);

● The instrument can be calibrated by using two methods: single-point calibration and two-point calibration, and the systematic error of the probe can be corrected by the basic calibration method;

● Storage function: 4 calibration workpieces can be saved. 26 groups of each category, 15 in each group, a total of 1560 measured values;

● Delete function: delete a single suspicious data that appears in the measurement, and also delete the data in the storage area to make a new measurement;

● Set the limit: the measured value outside the limit can be automatically alarmed;

● It has the function of power supply under-Voltage indication, and there is a beep prompt during operation, and the automatic shutdown mode.

● Metal shell: The fuselage is made of aviation aluminum metal shell, which has low anti-interference wear.

Meets standards

1. GB/T 4956-1985 Magnetic method for measuring the thickness of non-magnetic cladding on magnetic metal matrix

2. GB/T 4957-1985 Eddy current method for thickness measurement of non-conductive cladding on non-magnetic metal substrates

3. JB/T 8393-1996 Magnetic and eddy current cladding thickness measuring instrument

4. JJG 889-95 "Magnetoresistive Thickness Gauge"

5. JJG 818-93 "Eddy Current Thickness Gauge"

Principle

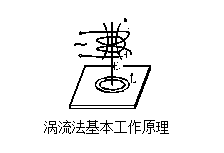

● This instrument adopts the measurement principle of eddy current, which can measure the thickness of non-conductive covering layer (such as enamel, rubber, paint, plastic, etc.) on non-magnetic metal substrates (such as copper, aluminum, zinc, tin, etc.).

A. Eddy current method (N-type probe): the use of high-frequency alternating current in the coil to generate an electromagnetic field, when the probe and the overlay contact, the metal matrix produces eddy current, and the coil in the probe has a feedback effect, and the thickness of the covering layer can be derived by measuring the size of the feedback effect.

- 1Application, Principle Introduction and Precautions for Selection of Pipeline Thickness Gauges

- 2Principle and Application Analysis of Silver Plating Thickness Gauge

- 3Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 4Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 5Principle, application and selection of stainless steel paints Coating Thickness Gauge

- 6Principle, application and selection of traffic coatings Coating Thickness Gauge

- 1ISO 《Non-magnetic metallic coatings on metallic and non-metallic basis materials — Measurement of coating thickness — Phase-sensitive eddycurrent method》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 4HG/T 3241-1989《Specifications for inner hole coating thickness gauge》

- 5GB/T 13448-2006《Test methods for Prepainted Steel Sheet》

Leeb231

Leeb231