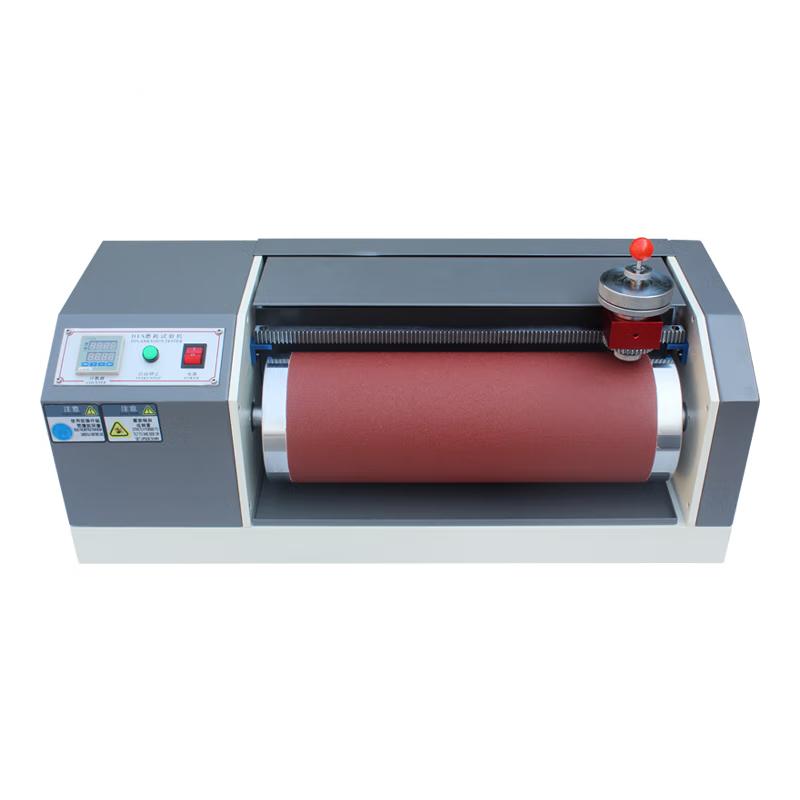

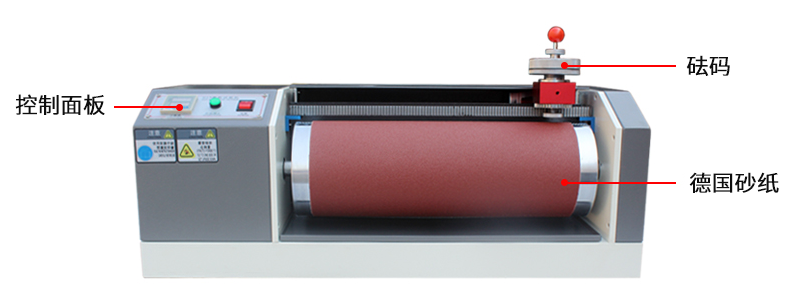

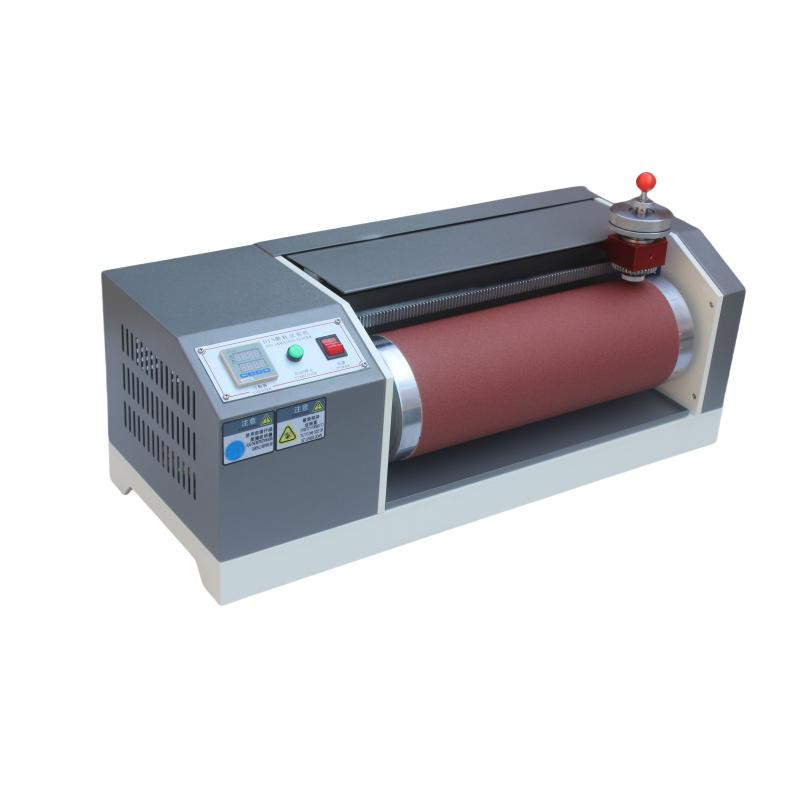

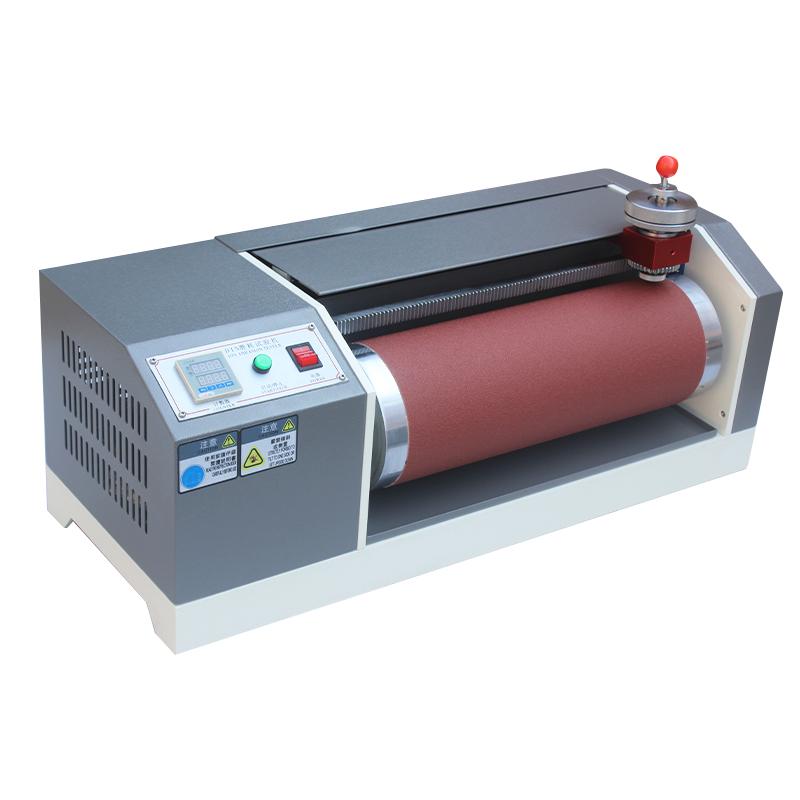

NBC-5611 DIN Wear testing machine

SEThe rolling diameter is 150mm, the lateral displacement of the fixture is 4.2mm/rolling lap, and the load is 2.5N, 5N, 10N. It is used for rubber, tires, conveyor belts, conveyor belts, soles, soft synthetic leather, leather, etc.

$1069.00/set

PromotionLoading...

Coupon

Model:

Factory

Factory NBC-5611 DIN Wear testing machineSPEC

Factory NBC-5611 DIN Wear testing machineDetails

Factory NBC-5611 DIN Wear testing machinePacking list

- SKU

- NB044667

- Rolling diameter

- 150mm

- Clamp lateral displacement

- 4.2Mm/roll per turn

- load

- 2.5N,5N,10N

- Rotation speed

- 40rpm

- Machine size

- 95*66*31cm

- Weight

- About 50kg

- Power supply Voltage

- 220V 50HZ

NBC-5611

DIN Wear testing machine

The rolling diameter is 150mm, the lateral displacement of the fixture is 4.2mm/rolling lap, and the load is 2.5N, 5N, 10N. It is used for rubber, tires, conveyor belts, conveyor belts, soles, soft synthetic leather, leather, etc.

Introduction

This machine complies with DIN-53516, ISO/DIS-4649, GB-9867. This machine is suitable for wear testing of elastic materials, rubber, tires, conveyor belts, shoe soles, soft synthetic leather, leather and other materials. It is effective and reproducible. performance and ease of operation. Roller diameter Ï150mm Roller length 460 mm Roller speed 40rpm Wear stroke 40 mm (20 mm) Wear speed 0.32 m/sec Inclination angle 3o Test piece diameter Ï16 mm Thickness 6~15 mm Test load 5N, 1N.

FAQ

QWe do sole wear test, which instrument is suitable?

A

The NBC-5611 DIN Wear resistance tester is specially designed for sole materials and meets international standards. It can accurately simulate the actual abrasion of the sole, and the test results are reliable.

QRubber conveyor belts need to be tested for wear resistance. What equipment should I choose?

A

This DIN Wear resistance tester is suitable and uses standard roller testing principles to accurately evaluate the wear resistance performance of rubber conveyor belts and help you control product mass.

QDIN Wear resistance tester maintenance needs to pay attention to what problems?

A

Regularly check the working status of the roller and Rotation speed Control system to keep the equipment clean and running smoothly.

QIn which industries is DIN Wear resistance tester suitable for quality control?

A

It is widely used in rubber, tire, conveyor belt, sole and other industries to evaluate the wear resistance performance and life prediction of products.

QWhat are the differences between DIN Wear resistance testers and Miscellaneous equipments?

A

NBC-5611 adopts large diameter rollers and stable Rotation speed, which is suitable for wear resistance testing of various materials. It is easy to operate and has high test efficiency and accuracy.

Knowledge

- 1Paint film abrasion resistance and test method thereof

- 2Paint film adhesion and test method thereof

- 3Introduction of varnish detection method and application

- 4Introduction to the principle and application of low temperature wear resistance Tester

- 5Basic Principle and Application Analysis of Asphalt Wear testing machine

- 6Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 7Principle, Application and Selection of Adhesive Tape Wear testing machine

- 8Introduction to common wear resistance test methods

Standard

NBC-5611

NBC-5611