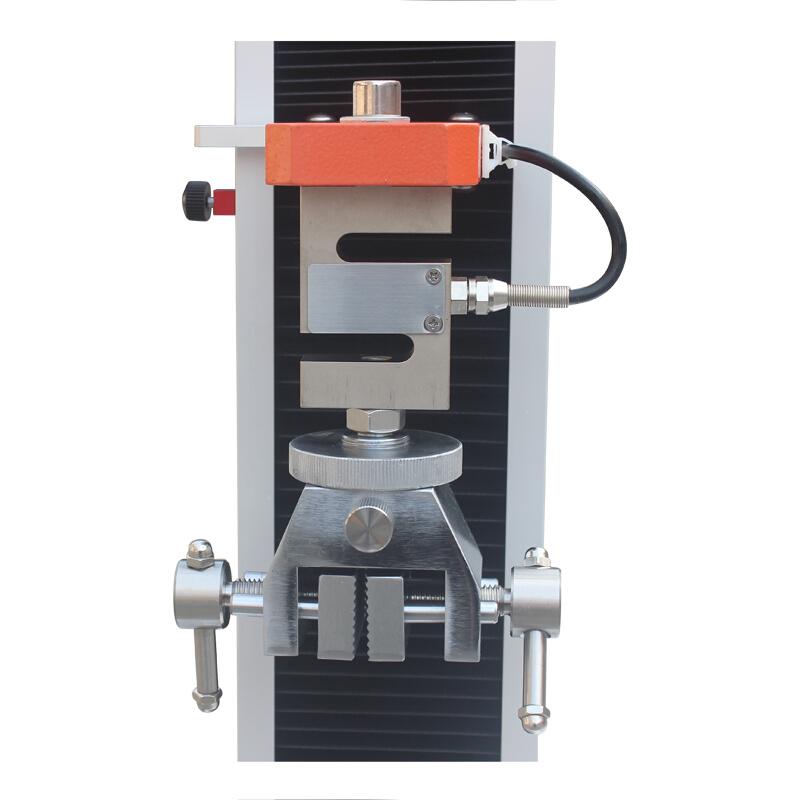

CHINA NBC-1021 (100KG) Tensile Tester Thin film disbonding Tester

SE

-

Lugong STX1000 Digital Display Single Arm Tensile Tester Single column tensile machine 1000N$ 1183.00

Lugong STX1000 Digital Display Single Arm Tensile Tester Single column tensile machine 1000N$ 1183.00 -

CHINA NBC-1021 Touch screen single column Tensile Strength Tester 100KG$ 1139.00SE

CHINA NBC-1021 Touch screen single column Tensile Strength Tester 100KG$ 1139.00SE -

Taichang TC-DLJ01 Microcomputer Tensile Tester 1000mm Stroke CHINA Sensors$ 1136.00SE

Taichang TC-DLJ01 Microcomputer Tensile Tester 1000mm Stroke CHINA Sensors$ 1136.00SE -

Taichang TC-DLJ01 Microcomputer Tensile Tester 1000mm stroke, imported Sensors$ 1293.00SE

Taichang TC-DLJ01 Microcomputer Tensile Tester 1000mm stroke, imported Sensors$ 1293.00SE -

Taichang TC-DLJ01 Tensile Tester stroke 600mm Chinese Sensors$ 1144.00SE

Taichang TC-DLJ01 Tensile Tester stroke 600mm Chinese Sensors$ 1144.00SE

Factory NBC-1021(100KG) Tensile TesterSPEC

Factory NBC-1021(100KG) Tensile TesterDetails

Factory NBC-1021(100KG) Tensile TesterPacking list

- SKU

- NB044690

- Capacity selection

- 100KG

- Measurement Accuracy

- ±1 %

- resolution

- 1/200000

- Test speed range

- 0~300mm/min

- effective travel

- 600mm

- Test space

- 120 mm

- Force unit

- kgf、gf、N、kN、lbf

- stress unit

- MPa、kPa、kgf/cm2、lbf/in2

- shutdown mode

- Upper and lower limit safety setting, specimen breakpoint sensing

- result output

- Micro printer with computer, including software

- Power system

- speed regulating motor

- optional

- Tension clamp (conventional)

- Machine Weight

- Approx. 40 kg

- Power

- 1PH、AC220V、50/60Hz

Introduction

A Tensile Testing Machine, also known as a Tensile Testing Machine, is an instrument used to measure the mechanical properties of materials such as tension, peeling, compression, yielding, bending and fracture. It is widely used in the fields of materials science and engineering, as well as in quality control and quality assurance processes. The Tensile Testing Machine consists of a load unit, sample fixture, displacement measurement equipment, control system and data acquisition system. The control system can precisely control the load applied to the sample and record mechanical property data during the test.

The following tests can be done:

Tensile test: used to measure the strength, elongation, breaking point and other properties of materials under tensile load.

Compression Test: Used to measure the strength and compressive modulus of a material under compressive load.

Bending test: used to measure the flexural strength and elastic modulus of a material under bending load.

Peel test: used to measure the peel strength of adhesives, coatings and other materials.

Fatigue testing: used to measure the fatigue life of materials under alternating loads.

Impact test: used to measure the toughness and impact resistance of materials under impact loads.

Applications

Suitable for tensile strength, peel strength, deformation rate, breakage force, peel force of plastic films, composite films, adhesives, adhesive tapes, medical patches, protective films, release papers, rubber, artificial leather, paper fibers and other products , opening force and other performance tests.

Application

Tapes, automobiles, ceramics, composite materials, construction, food and medical equipment, metal, paper, packaging, rubber, textiles, wood, communications and various special-shaped materials

- 1GB/T 44824-2024《Biaxial stretching polylactic acid film》

- 2JC/T 483-2022《Polysulfide sealant for building》

- 3YB/T 4634-2017《Continuously hot-dip aluminum-zinc-magnesium alloy coated steel sheet and strip》

- 4SL/T 807-2021《Guidelines for applications of epoxy resin grouts in hydraulic structures》

- 5FZ/T 75004-2014《Coated fabrics.Determination of elongation and tensile permanent deformation》

- 6HG/T 2580-2022《Rubber-or plastics-coated fabrics-Determination of tensile strength and elongation at break》

- 7JG/T 512-2017《General technical requirements for building exterior wall coating system》

- 8HG/T 4372-2012《Composite pipes and fittings for chemical industry》

- 9HG/T 6102-2022《Pressure sensitive adhesive tapes of BOPP for general purpose》

- 10JB/T 9375-2014《Mechanical Tensile Testing Machines.Specification》

NBC-1021(100KG)

NBC-1021(100KG)