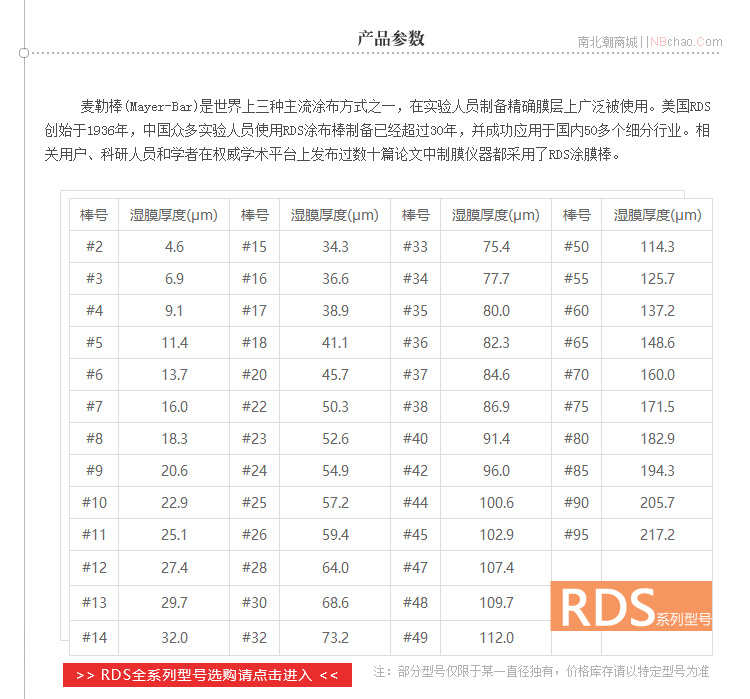

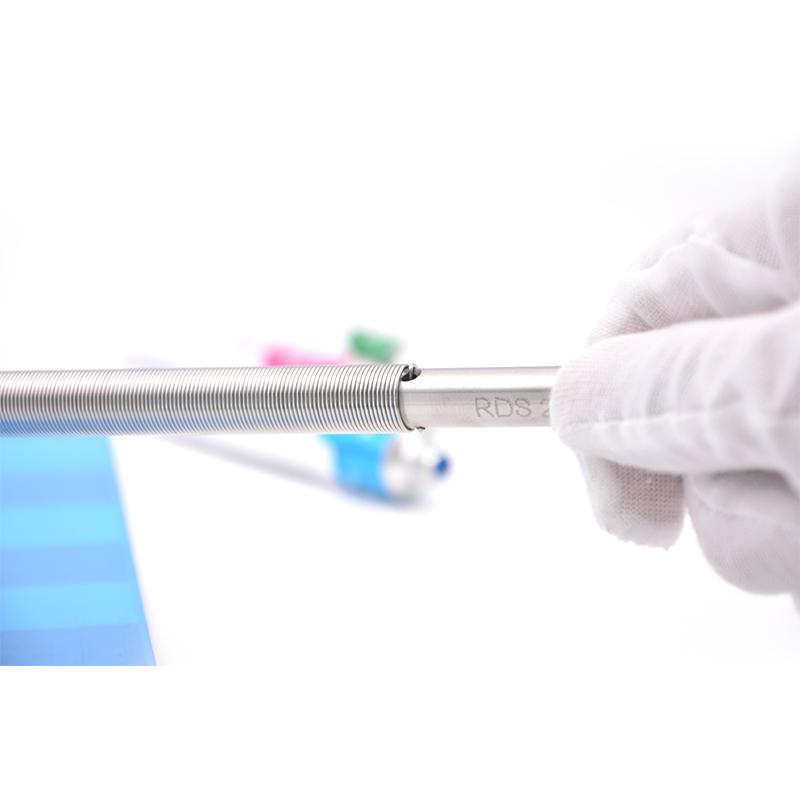

RDS 22 #1/4 "wire-wound Applicator rod film thickness 50.3μm Wire diameter 0.56mm

SEApplicator rod adopts winding process, Wire diameter 0.56mm, rod diameter 6.35mm, main rod and steel wire are stainless steel, can film 50.3μm.

$155.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 22 #3/8 "Applicator rod WFT 50μm Length 400mm$ 161.00SE

RDS 22 #3/8 "Applicator rod WFT 50μm Length 400mm$ 161.00SE -

RDS 22 #1/2 "Steel Wire Drawdown Rod film thickness 50.3μm Wire diameter 0.56mm$ 179.00SE

RDS 22 #1/2 "Steel Wire Drawdown Rod film thickness 50.3μm Wire diameter 0.56mm$ 179.00SE -

Japan OSP-50/400 scraping reticulated stick WFT 50μm length 400mm$ 172.00SE

Japan OSP-50/400 scraping reticulated stick WFT 50μm length 400mm$ 172.00SE -

RDS 22 #1/4 "Coating Metering rod film thickness 50.3μm rod diameter 6.35mm$ 155.00SE

RDS 22 #1/4 "Coating Metering rod film thickness 50.3μm rod diameter 6.35mm$ 155.00SE -

RDS 22 #3/8 "Molded wet-Film Applicator 50.3μm Spreader$ 161.00SE

RDS 22 #3/8 "Molded wet-Film Applicator 50.3μm Spreader$ 161.00SE

RDS 22# 1/4" Applicator rod 1/4 "SPEC

RDS 22# 1/4" Applicator rod 1/4 "Details

RDS 22# 1/4" Applicator rod 1/4 "Packing list

- SKU

- NB004482

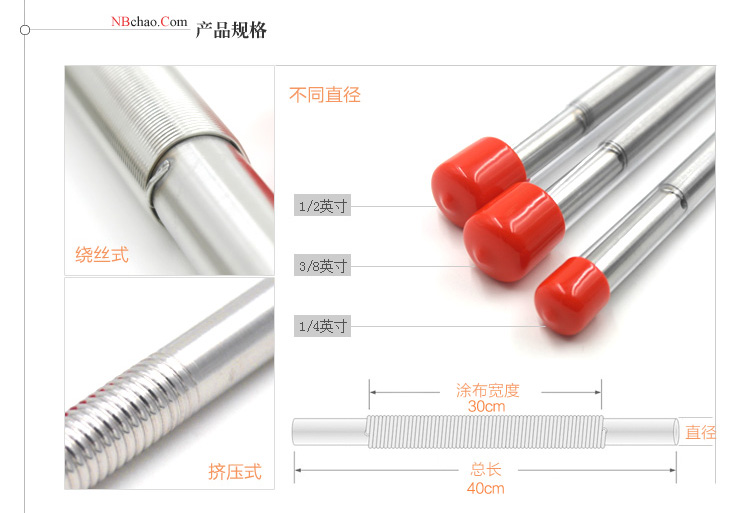

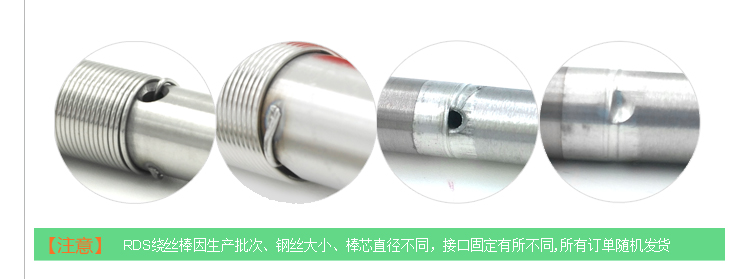

- Production process

- wire-wound

- WFT

- 50.3μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.56mm

- principle

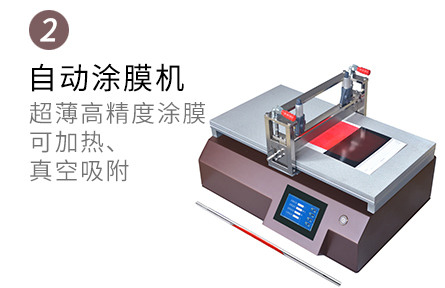

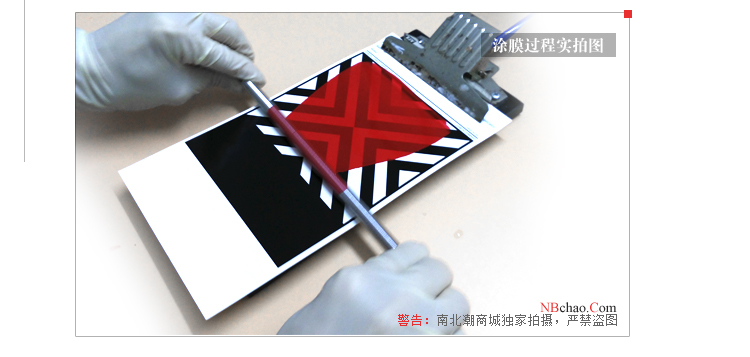

- Through different grooves, ink control is applied to film, paper and other substrates by roller painting and scratch coating. Universal for high-precision wire-rod film applicators.

- function

- Coating is used to uniformly coat the surface of the substrate to form a flat, uniform thickness coating.

22# 1/4"

Applicator rod 1/4 "

Applicator rod adopts winding process, Wire diameter 0.56mm, rod diameter 6.35mm, main rod and steel wire are stainless steel, can film 50.3μm.

|  |  |

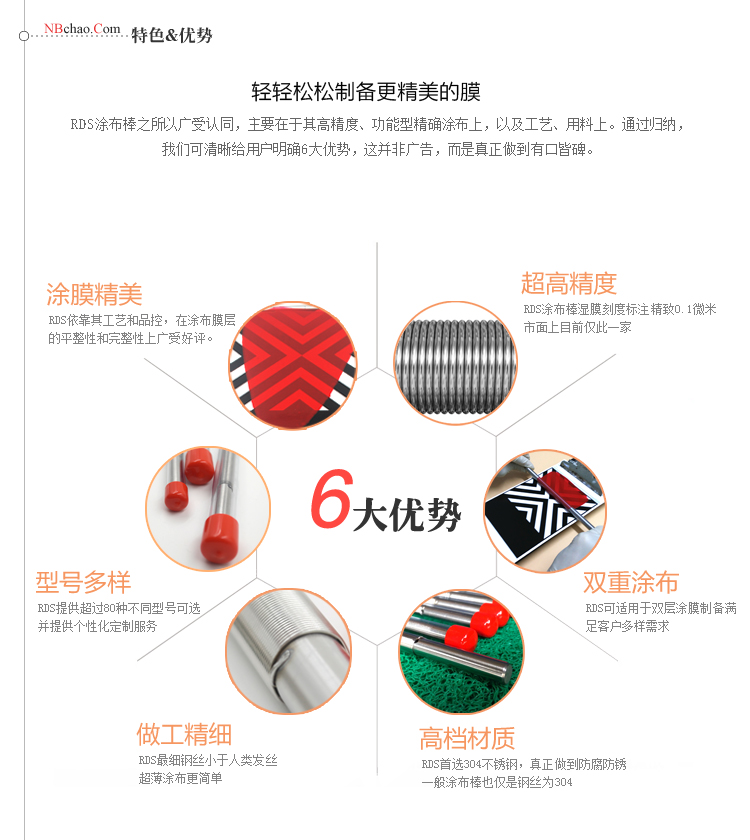

The RDS wire rod coater enjoys a high reputation in the coating rod industry. Its wire-wound wire rod coater inherits the principle of the traditional Meyer rod, and is recognized for its unique 0.1 micron high precision and high quality. It is favored by most users in the industry, and the formed coating rod is processed by cold extrusion process, without winding steel wire, and it solves the trouble of cleaning and easy clogging of impurities for users. Both have their own advantages. According to users free choice of usage habits. Among them, the RDS#22 wire Bar Coater can prepare a wet film thickness of 50.3 microns.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QColor coating bar is universal, right?

A

This one can be used for inks scraping color matching, wet film thickness is 50.3μm.

QDo you have any shorter RDS?

A

RDS are all 400mm long.

QIs there a 22 #Spreader Applicator rod? wide-wounded.

A

Hello, yes, RDS22 #.

QIs this kind of wire rod used for the preparation of hot melt adhesive backing layer?

A

Yes, this model can prepare wet film 50um, which can be scraped by hand or matched with motorized film on the film machine.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QI want to do a test about the GB/T13217.1 standard, is this film scraper okay?

A

Sure

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

Standard

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2HG/T 2006-2006《Thermosetting powder coatings》

- 3GB/T 1727-2021《General methods for preparation of coating films》

- 4GB/T 7044-2022《Colour carbon black》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 3355-2003《Various colour nitrocellulose primer》

- 8HG/T 3951-2007《Water based colorants for architectural coatings》

- 9HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 10ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

22# 1/4"

22# 1/4"