China Laboratory Perovskite Film Applicator with imported bar with air knife + air knife bracket

SE

-

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE -

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE -

HUINUO TM3300pro+ High-precision Rod & Drawdown Blade Coater with Heated Vacuum Table$ 6180.00SE

HUINUO TM3300pro+ High-precision Rod & Drawdown Blade Coater with Heated Vacuum Table$ 6180.00SE -

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE -

China Intelligent Program Control Film Applicator TBJ-X3-DJ19 bar + Drawdown blade + Heating + Vacuum chuck type$ 7276.00SE

China Intelligent Program Control Film Applicator TBJ-X3-DJ19 bar + Drawdown blade + Heating + Vacuum chuck type$ 7276.00SE

zy TBJ-X3-ABO3 Automatic Film ApplicatorSPEC

zy TBJ-X3-ABO3 Automatic Film ApplicatorDetails

zy TBJ-X3-ABO3 Automatic Film ApplicatorPacking list

- SKU

- NB044876

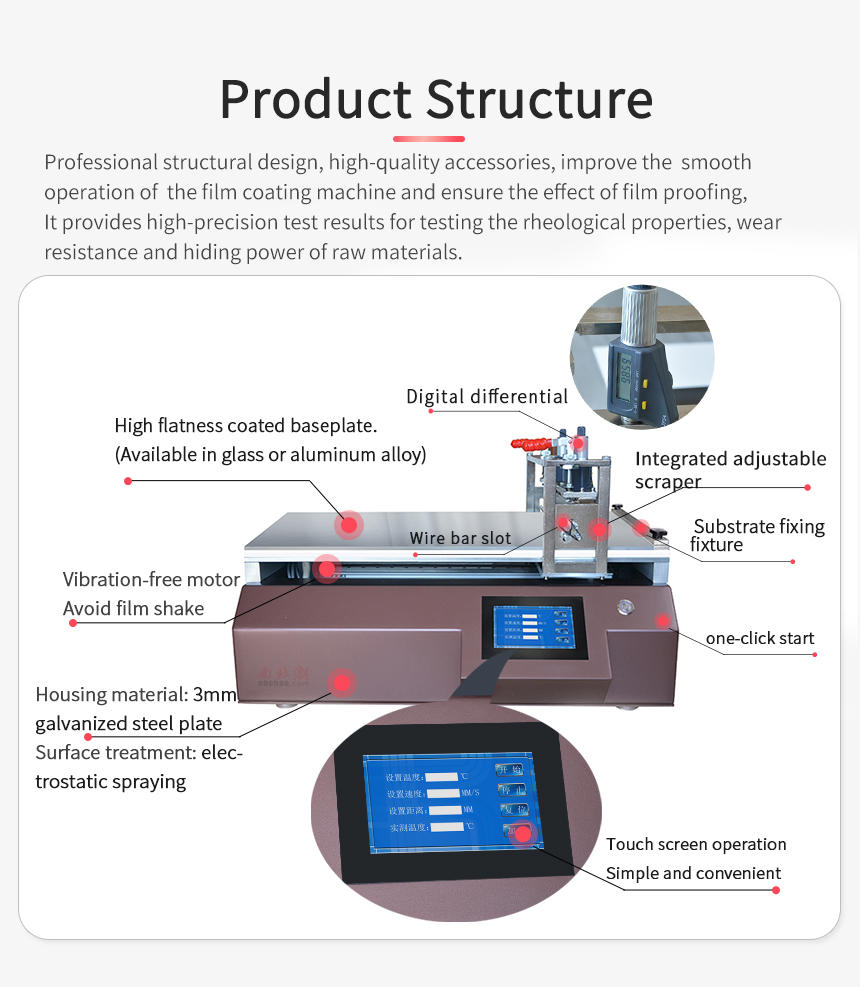

- Spreader Accuracy

- ±0.003mm

- Spreader Film thickness range

- 0~10Mm drawdown blade can be lifted

- Coating speed

- 0.1-40mm/s

- Coating size

- 350*600mm

- Rod Film thickness range

- 1~ 571.5 μm (Spreader Film thickness according to bar type)

- vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Vacuumpump size

- 380*180*280mm

- Mayer Rod Accuracy

- ±0.001mm

- Host Power Supply

- 220V 50Hz

- net Weight

- 65KG

- speed control

- Infinitely variable speed

- Coating table material

- aluminum alloy

- Spreader Accuracy

- 0.001mm

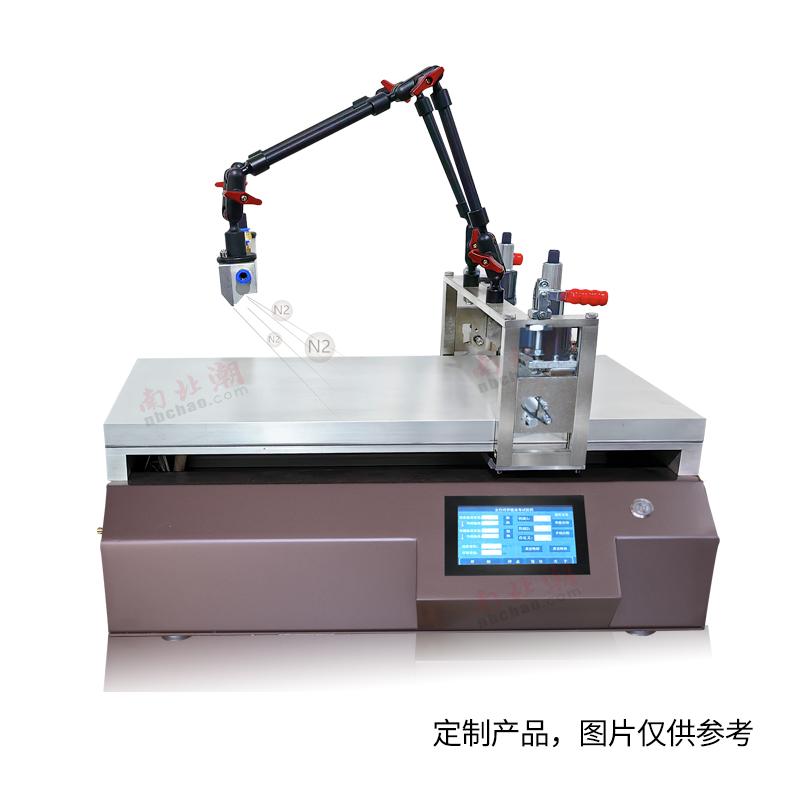

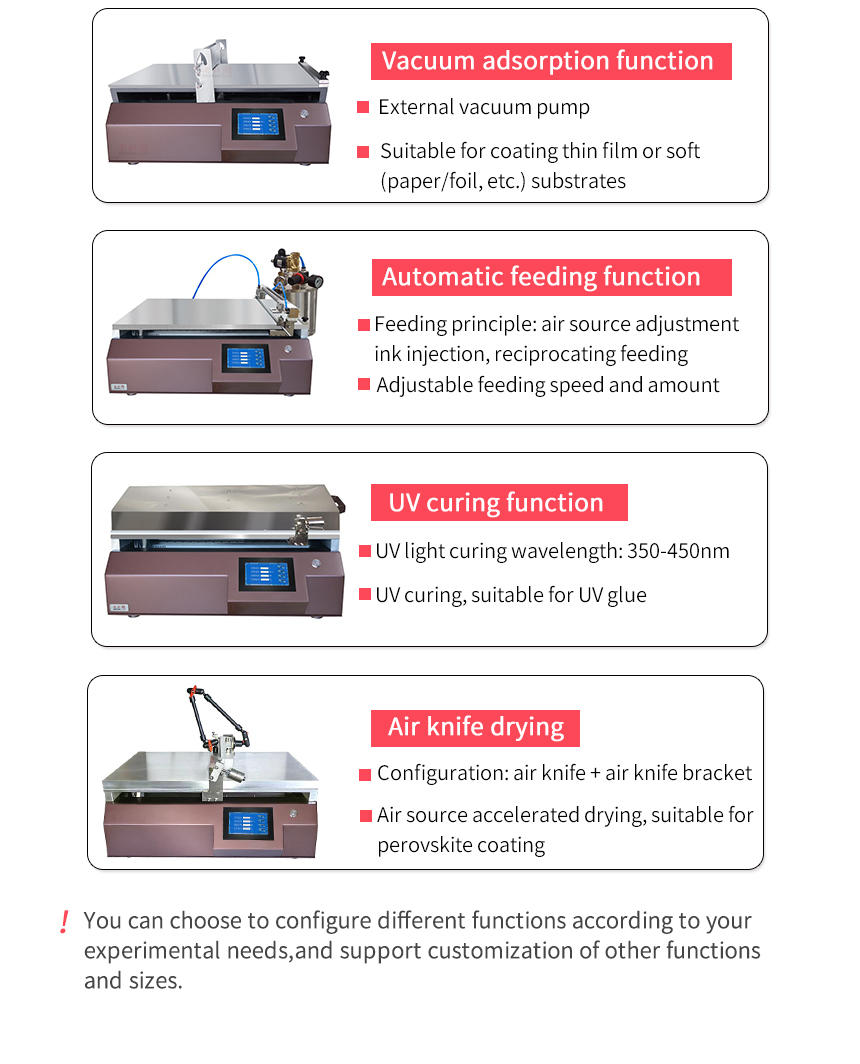

- configuration function

- Air knife + air knife bracket

- Dimensions

- 630*410*520mm

- Heating temperature range

- RT+~180℃

- Temperature Uniformity

- ±3℃

- Air knife gap

- 0.05mm

- Air knife Accuracy

- ±0.002mm

- Coating method

- Bar + drawdown blade + air knife

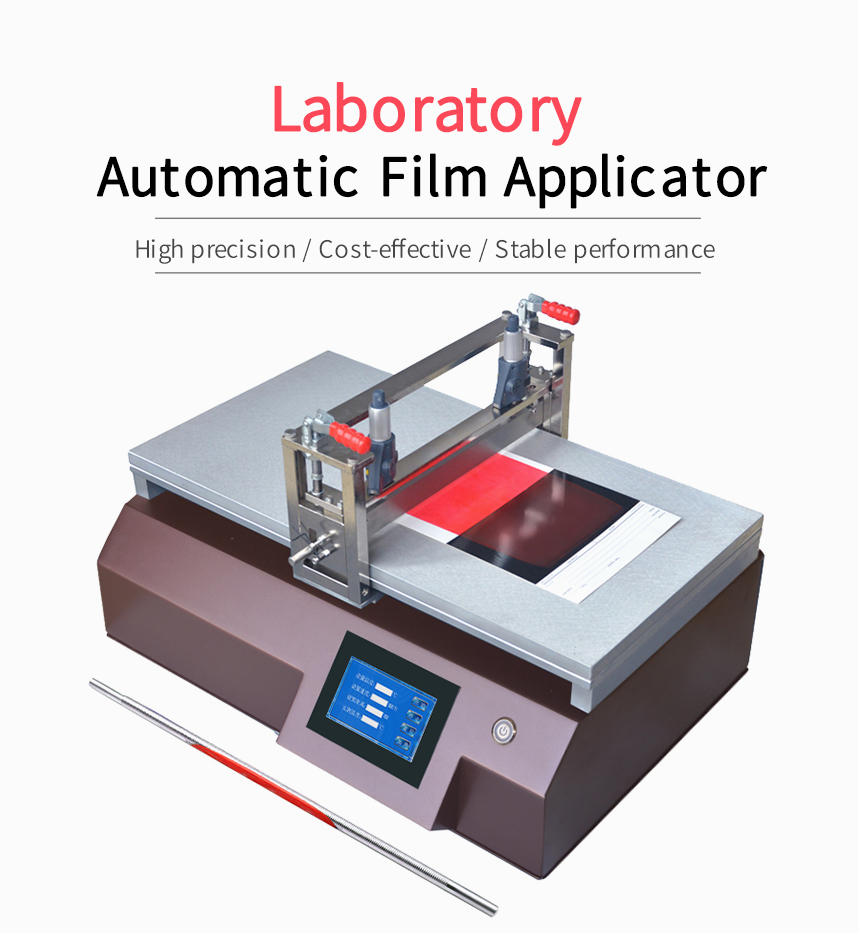

product description

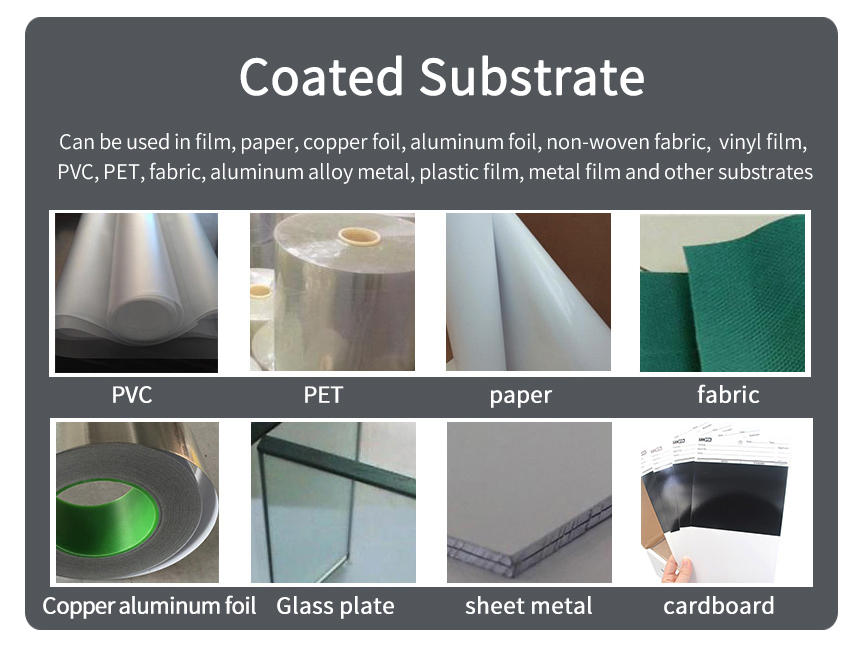

The perovskite-specific coating machine is equipped with an imported high-precision wire rod coater, which has heating and vacuum adsorption functions. It is equipped with an air knife and an air knife holder. It uses nitrogen as the gas source to accelerate drying of the perovskite solution and achieve 360-degree air knife Angle adjustment, the thinnest dry film can reach nanometer level.

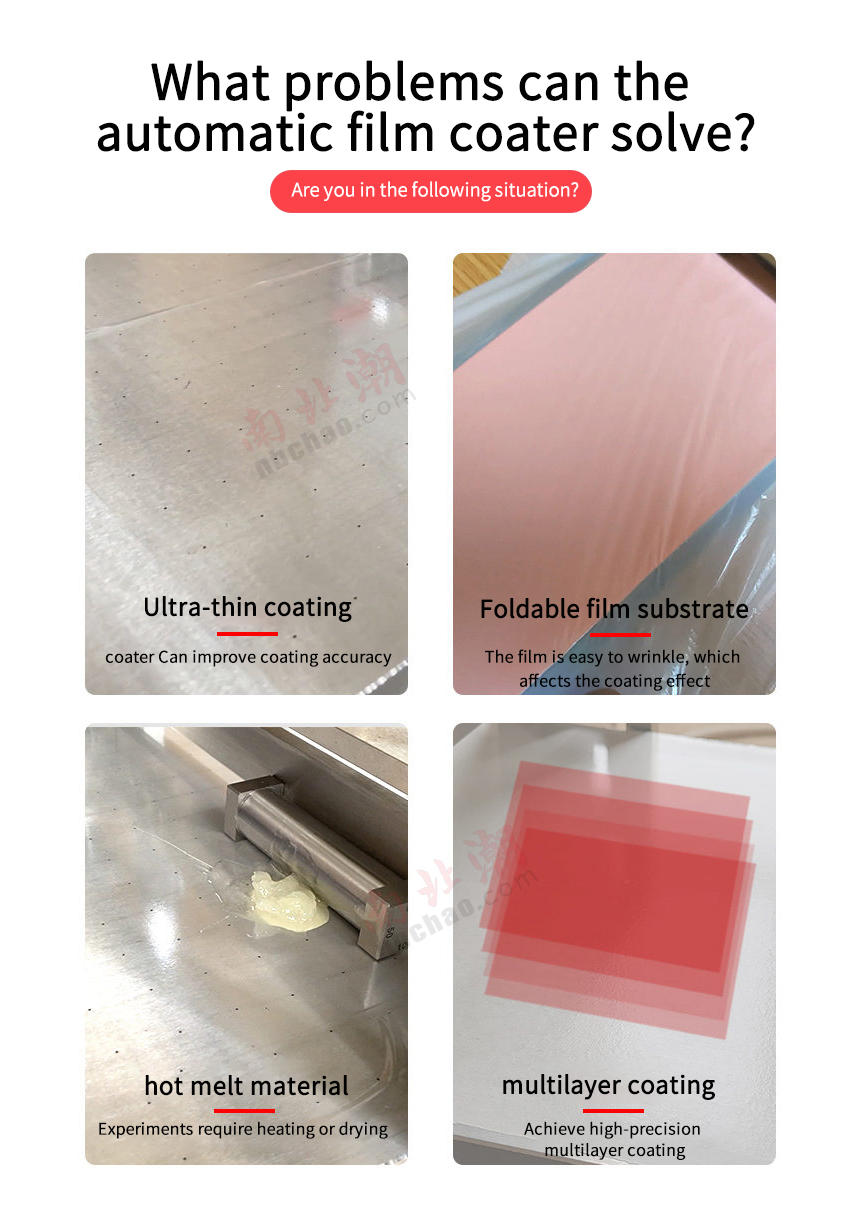

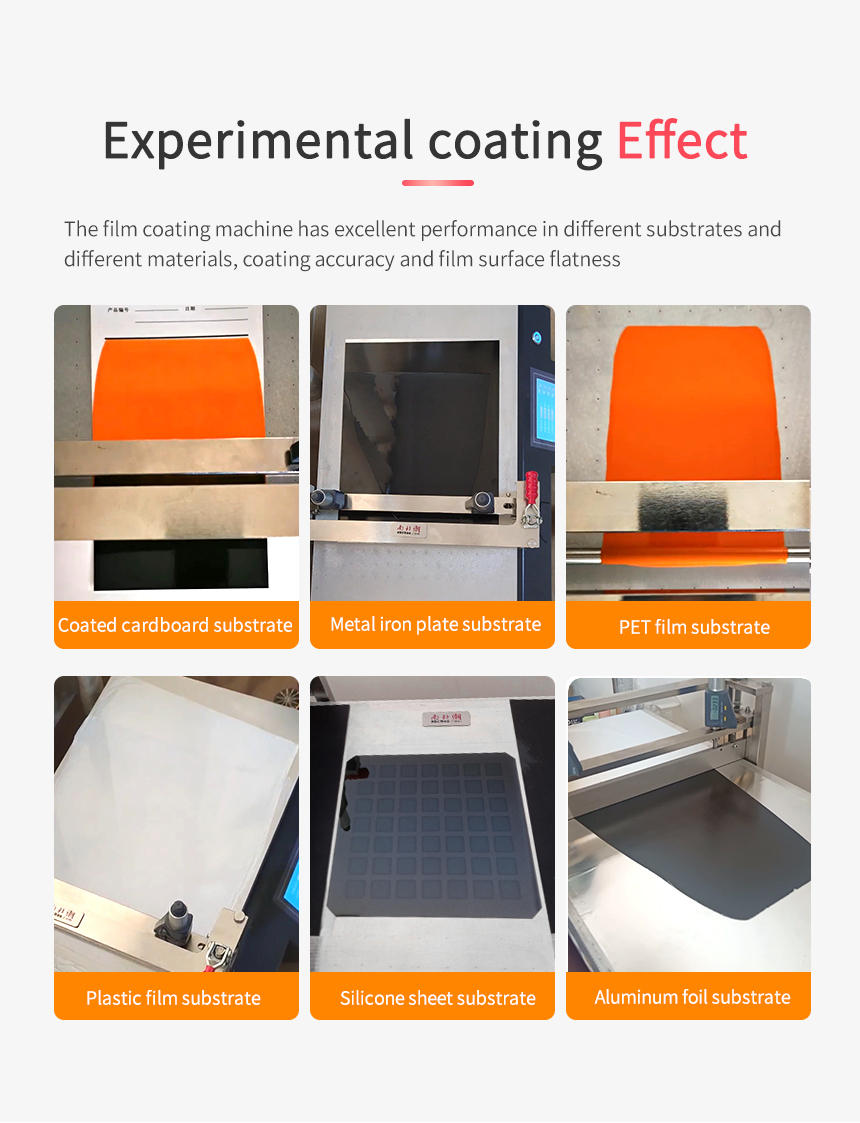

With the emergence of the film coating machine, the main factors that affect the coating film are the coating speed and the pressure exerted on the Film Applicator. Therefore, the coatings applied manually are often inconsistent, especially the differences between different people. This makes it difficult to compare test results between samples. The automatic film coating machine is carefully designed to allow operators to easily apply precise wet films on different substrates, greatly improving the reproducibility of coating films.

Optional

- 1Types of Amino resins and Their Applications in Coatings

- 2Technical explanation and operation guide of heating ginger sticker coater

- 3Application and Experimental Study of Film Coating Adhesive Technology

- 4Lab Film Applicators for prepative polypropylene (PP) nitrile films

- 5Technical Principle and Operation of Anode Film Applicator

- 6Comparison of Different Spreader Methods of Small Coating coater

- 7Perovskites could change the future of solar energy

Karen Frances Eng

- 8Application and Advantages of Coater in Antipyretic Sticker prepative

- 9Advantages of drawdown blade method in preparation of perovskite solar cells

- 10Laboratory proofing coater technology comparison and application review

TBJ-X3-ABO3

TBJ-X3-ABO3