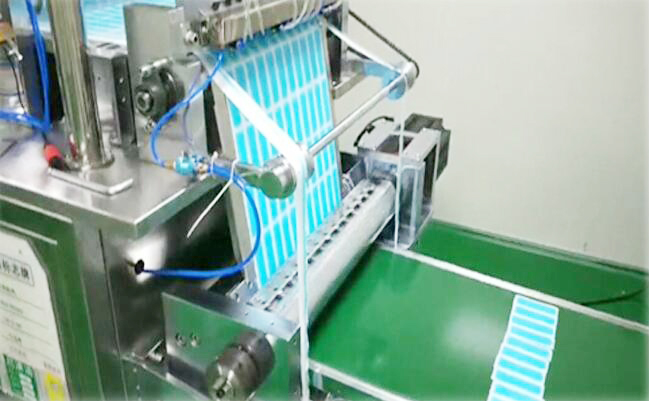

CHINA NBC-6026D hydrogel Coater application width 480mm

SE

Factory NBC-6026D Hydrogel coaterSPEC

Factory NBC-6026D Hydrogel coaterDetails

Factory NBC-6026D Hydrogel coaterPacking list

- SKU

- NB045141

- Effective Spreader Width

- ≤480mm

- Coil diameter

- 500-700mm

- power

- 1.4KW

- Power Supply

- Three-phase 220V

- Dimensions

- 2650 * 1100 * 1700mm (L * B * H), floor area: 2.3 m2 (including conveyor belt)

- Weight

- 1200kg

- Equipment power

- Servo Control system

- unroll

- With tension control

- Control system

- Touch screen (Kunlun Tongtai)

- Appearance material

- The equipment material is 304 stainless steel protection

- Vertical cutter installation

- 4

- Toolbox

- 1 (with: Thickness gauge, a set of hexagonal wrenches, a hob adjustment wrench, a hob separation crowbar, a spare screw batch, a screw driver, 3 trachea interfaces)

- inflated shaft

- 2

- maintenance

- The operating part of the equipment is cleaned with alcohol and anti-rust oil to ensure that the equipment does not rust.

Introduction

NBC-6026D hydrogel coating machine is a composite coating machine used to produce gel products. It can be used to produce spunlace non-woven fabrics, elastic fabrics and various gel products (such as: antipyretic patches, cold compress patches products, etc.). The main function of the hydrogel coater is to evenly coat the hydrogel on the surface of the substrate to ensure the uniformity and quality of the coating. The coating machine usually includes a coating head, a control system and a conveyor system. The coating head is responsible for evenly coating the hydrogel on the substrate. The control system is used to set and monitor coating parameters, while the conveying system is used to transport the substrate during the coating process to ensure continuous coating. sex and consistency.

Features

It has a high-precision coating system that can achieve uniform and precise coating.

The hydrogel coating machine adopts an automated control system that enables intelligent management of the coating process.

With efficient coating speed and production efficiency, the hydrogel coating machine is suitable for large-scale production.

The parameters of the coating machine, such as coating speed, thickness, temperature, etc., can be adjusted according to specific needs.

- 1Application of small coater in film casting solution

- 2Double-sided tape coater: Selection and Troubleshooting Guide

- 3Tape laboratory coater technology and film accuracy optimization elements analysis

- 4Review of laboratory film coater technology and selection method

- 5The working principle and application of inks heating coater

- 6Selection skills of laboratory small automatic coating machine

- 7Application and Technical Advantage Analysis of Coater in LR Film

- 8Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- 9Application of small coater in analgesics film

- 10Laboratory proofing coater technology comparison and application review

NBC-6026D

NBC-6026D