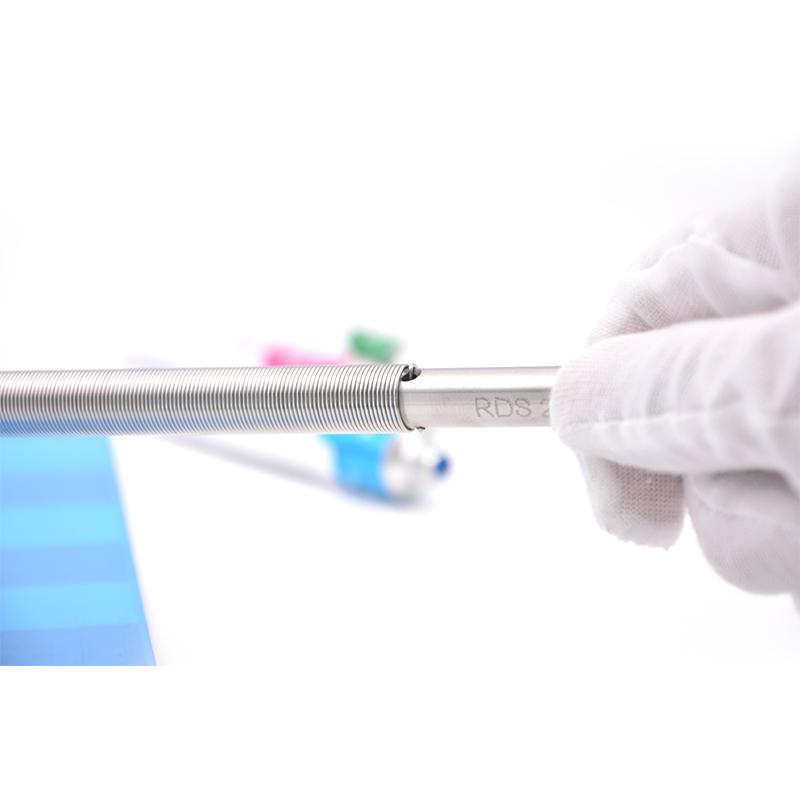

Can film 13.7 μ m, using winding process, Wire diameter 0.15mm, rod diameter 6.35mm, the main rod and steel wire are stainless steel.

$156.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 6 #3/8 "Mayer Rods WFT 13.7μm Length 400mm$ 162.00SE

RDS 6 #3/8 "Mayer Rods WFT 13.7μm Length 400mm$ 162.00SE -

RDS 6 #1/4 "roller painting rod film thickness 13.7μm rod diameter 6.35mm$ 156.00SE

RDS 6 #1/4 "roller painting rod film thickness 13.7μm rod diameter 6.35mm$ 156.00SE -

RDS 6 #1/2 "steel wire scraping rod, rod Applicator film thickness 13.7μm Wire diameter 0.15mm$ 181.00SE

RDS 6 #1/2 "steel wire scraping rod, rod Applicator film thickness 13.7μm Wire diameter 0.15mm$ 181.00SE -

RDS 6 #3/8 "coating bar No. 6 molded RDS coating bar 13.7 μm$ 162.00SE

RDS 6 #3/8 "coating bar No. 6 molded RDS coating bar 13.7 μm$ 162.00SE -

RDS 6 #1/2 "inks Applicator rod Molded rds Spreader rod 13.7 μm$ 181.00SE

RDS 6 #1/2 "inks Applicator rod Molded rds Spreader rod 13.7 μm$ 181.00SE

RDS 6# 1/4" Applicator rod 1/4 "SPEC

RDS 6# 1/4" Applicator rod 1/4 "Details

RDS 6# 1/4" Applicator rod 1/4 "Packing list

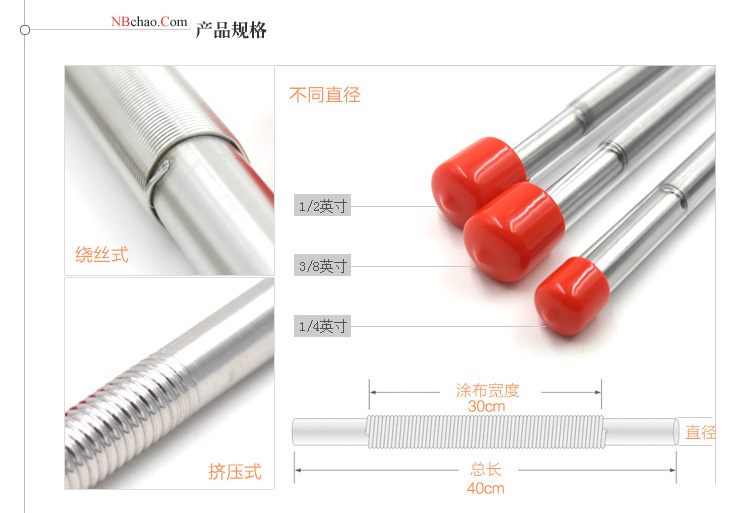

- SKU

- NB004515

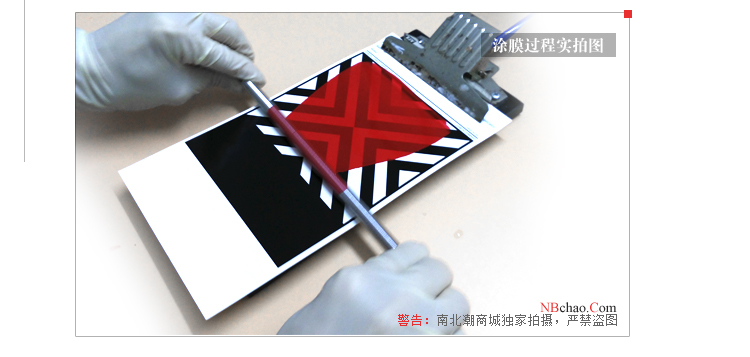

- Production process

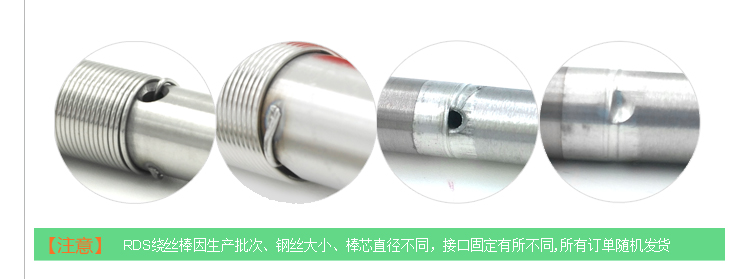

- wire-wound

- WFT

- 13.7μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.15mm

- principle

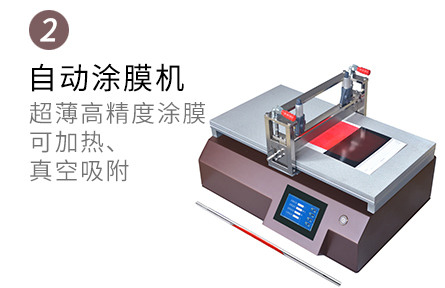

- Through different grooves, ink control is applied to film, paper and other substrates by roller painting and scratch coating. Universal for high-precision wire-rod film applicators.

- function

- Coating is used to uniformly coat the surface of the substrate to form a flat, uniform thickness coating.

6# 1/4"

Applicator rod 1/4 "

Can film 13.7 μ m, using winding process, Wire diameter 0.15mm, rod diameter 6.35mm, the main rod and steel wire are stainless steel.

|  |  |

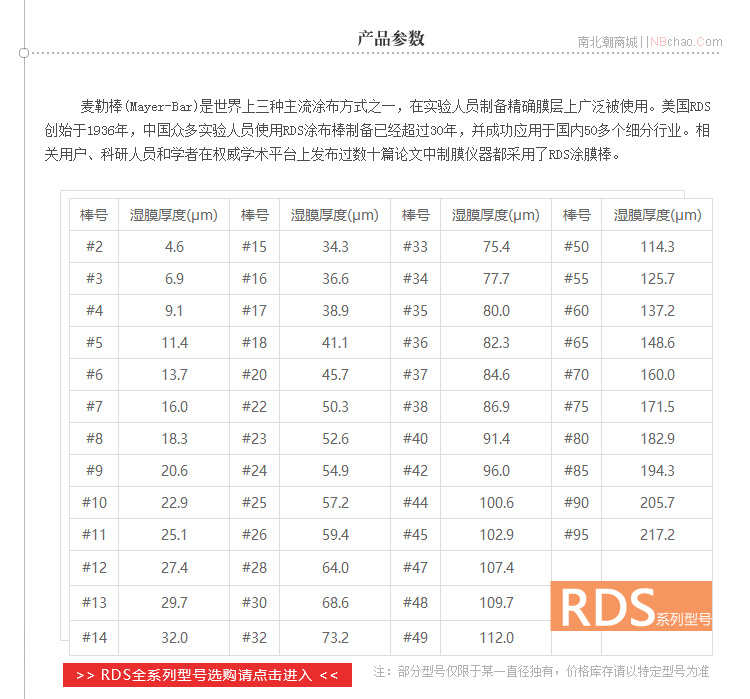

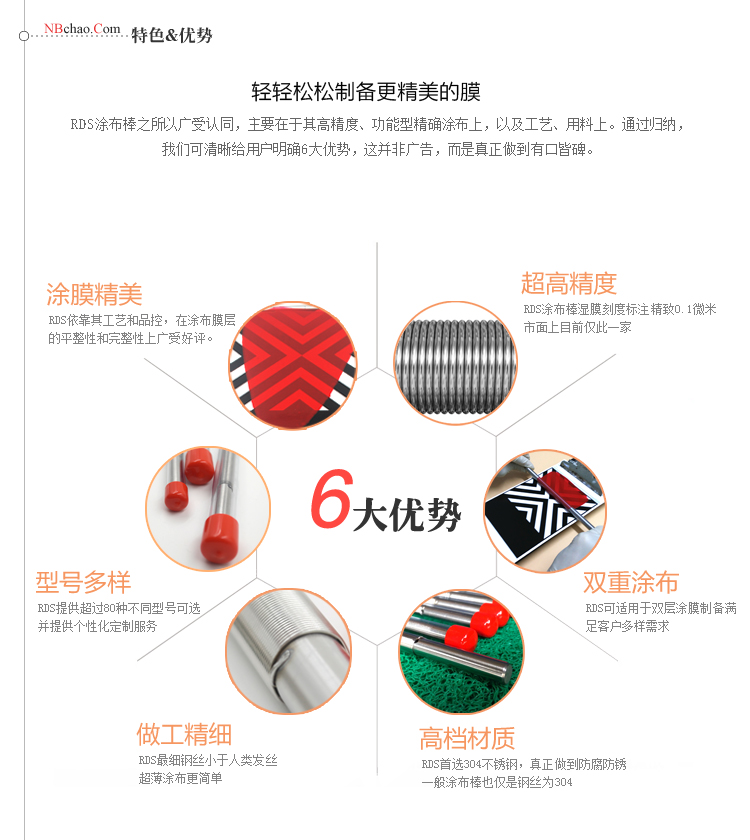

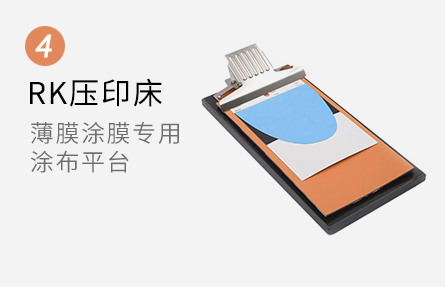

RDS No. 6 wire rod coater is a coating rod with a wet film thickness of 13.7 microns. The length of the RDS wire rod coater is 40mm. According to different user needs, RDS has developed two types: wire winding type and forming type. For wire Bar Coaters, the wet film thickness prepared by the same type of coating bar is the same, but there will be differences in the amount of coating applied. The forming type wire rod coater currently only has a diameter of 6.35mm, while the wire-wound type has three diameters of 9.5mm, 6.35mm, and 12.7mm, and the diameter of 9.35mm is more widely used.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QIt's all size 6, what's the difference between 3/8 and 1/4?

A

3/8 and 1/4 are the diameter of the rod, in inches. That is, the diameter of one rod is 9.5mm and the diameter of the other is 6.35mm. Miscellaneous is the same.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QI am a plastic color printing Encasement factory. What stick number do you generally use? The previous company used imported ones, and the stick said 6.

A

Hello, according to your picture, it is the No. 6 stick of RDS.

QDoes this film scraper conform to ASTMD4147 standard?

A

This film scraper is suitable for ASTMD4147. Please consult customer service for detailed application definition.

Q6 #What is the thickness of the Spreader Film?

A

Hello, different brands of 6 #Spreader sticks correspond to different Spreader Film thicknesses. The No. 6 wire rod of RDS is 13.7 μm; the No. 6 wire rod of RK is 60 μm; the No. 6 wire rod of OSP and Spreader, modern is 6 μm.

QOur company is a solar backplane, the laboratory needs to use a scraper, want to consult, want to achieve the film thickness in our mind, how to choose the rod number, no thickness of dry film can not refer to ah, before using the rds6 scraper, coated with a thickness of dry film is 4 microns, if I want to reach 6 to 8 microns, can you suggest?

A

It can be roughly calculated according to dry film = wet film × solid parts. The wet film of RDS No. 6 rod is 13.7 μm, and the solid content is about 29% by calculation. If you want to make 6 μm and 8 μm dry films, you need to scrape the wet film 20.5 microns and 27.4 microns, which corresponds to RDS rod, which can be close to RDS 9 #and RDS 12. Thank you for your consultation.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

6# 1/4"

6# 1/4"