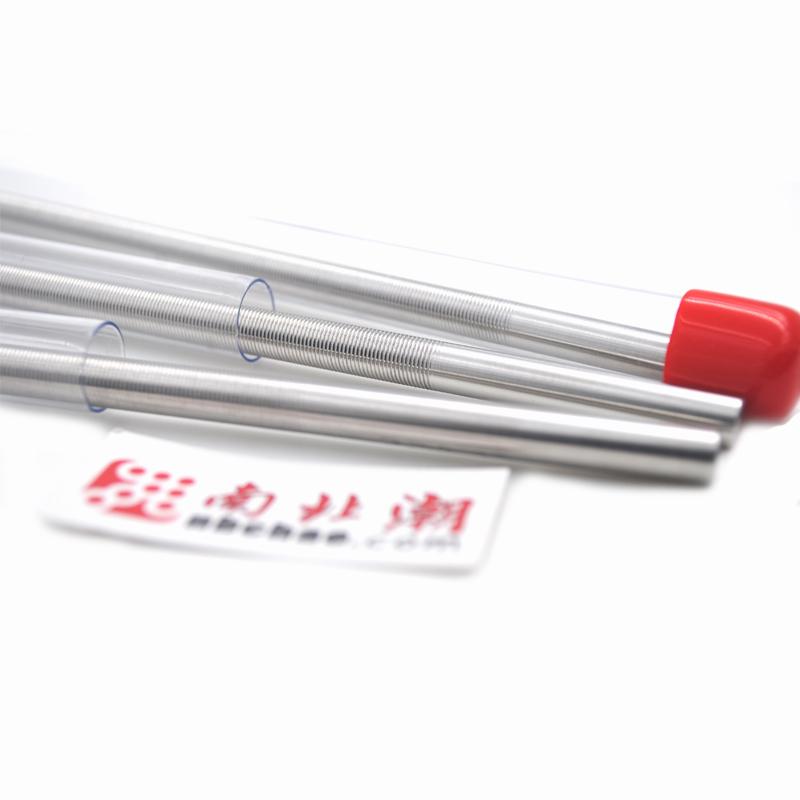

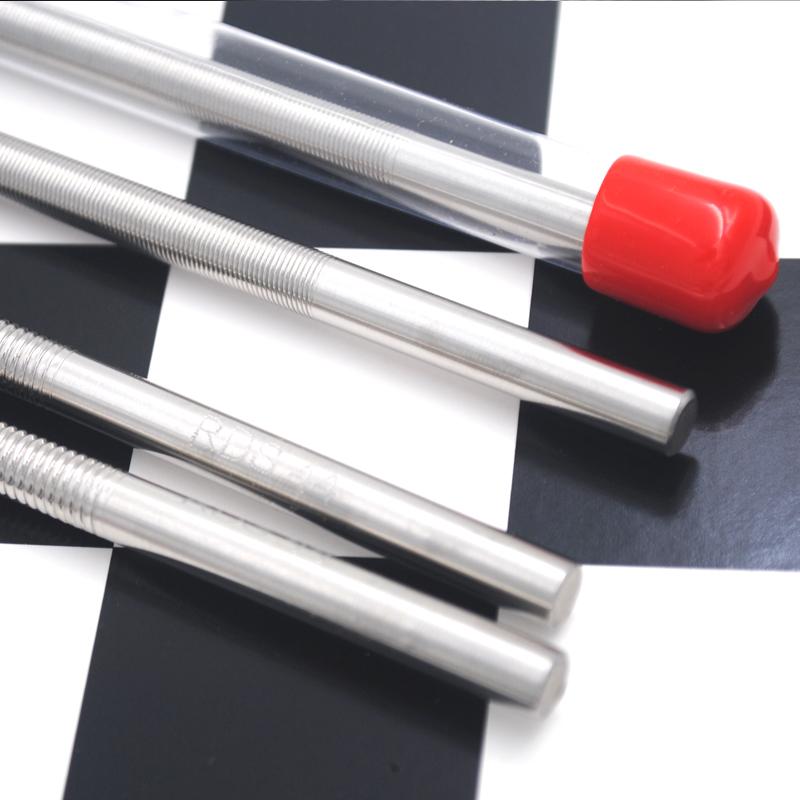

RDS 26 #1/4 "printing roll Wire-wound drawdown Bar film thickness 59.4μm rod diameter 6.35mm

SE-

RDS 26 #3/8 "Applicator rod WFT 59.4μm Length 400mm$ 162.00SE

RDS 26 #3/8 "Applicator rod WFT 59.4μm Length 400mm$ 162.00SE -

RDS 26 #1/2 "Steel Wire Drawdown Rod film thickness 54.9μm Wire diameter 0.66mm$ 181.00SE

RDS 26 #1/2 "Steel Wire Drawdown Rod film thickness 54.9μm Wire diameter 0.66mm$ 181.00SE -

UK RK KHC.11.6 Wire-wound drawdown Bar Coating Applicator WFT 60μm orange glue head No. 6 rod$ 168.00SE

UK RK KHC.11.6 Wire-wound drawdown Bar Coating Applicator WFT 60μm orange glue head No. 6 rod$ 168.00SE -

Japan OSP-60/60 Coating bar WFT 60μm length 60mm$ 116.00SE

Japan OSP-60/60 Coating bar WFT 60μm length 60mm$ 116.00SE -

RDS 26 #1/4 "wire-wound Applicator rod film thickness 59.4μm Wire diameter 0.66mm$ 156.00SE

RDS 26 #1/4 "wire-wound Applicator rod film thickness 59.4μm Wire diameter 0.66mm$ 156.00SE

RDS 26# 1/4“ Applicator rod 1/4 "SPEC

RDS 26# 1/4“ Applicator rod 1/4 "Details

RDS 26# 1/4“ Applicator rod 1/4 "Packing list

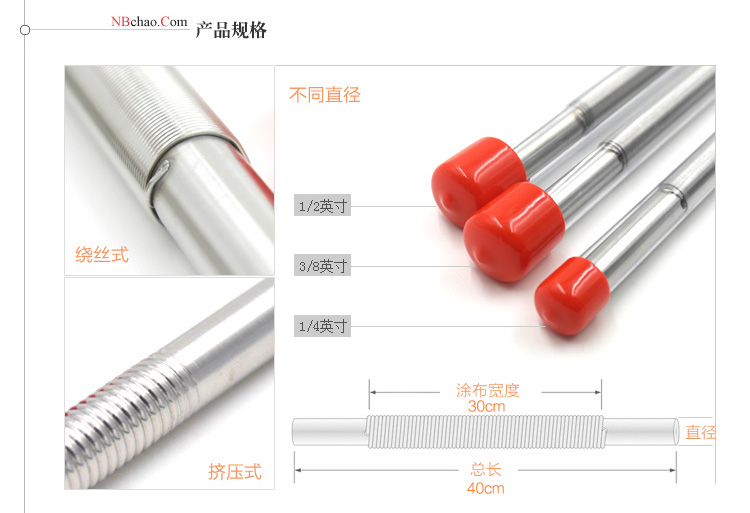

- SKU

- NB004556

- Production process

- formed

- WFT

- 59.4μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

|  |  |

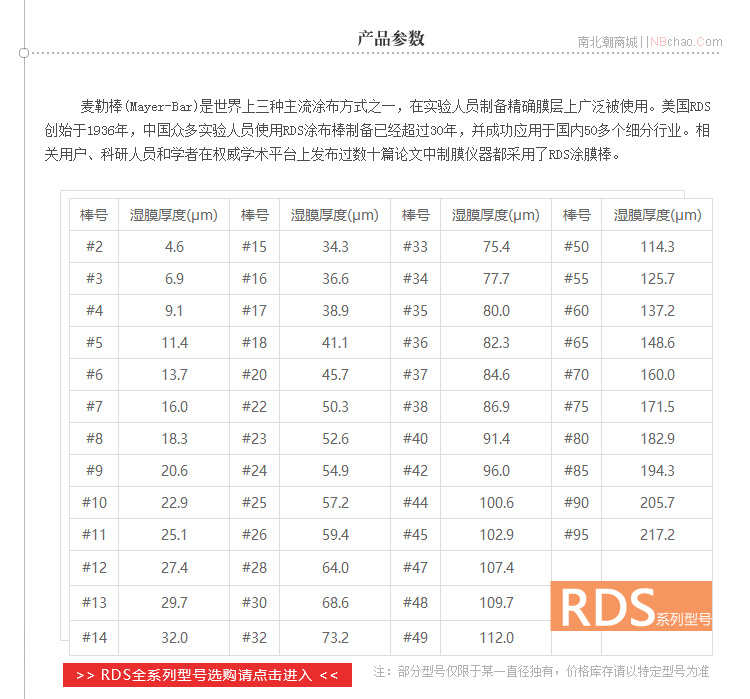

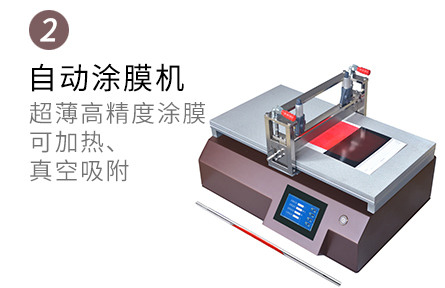

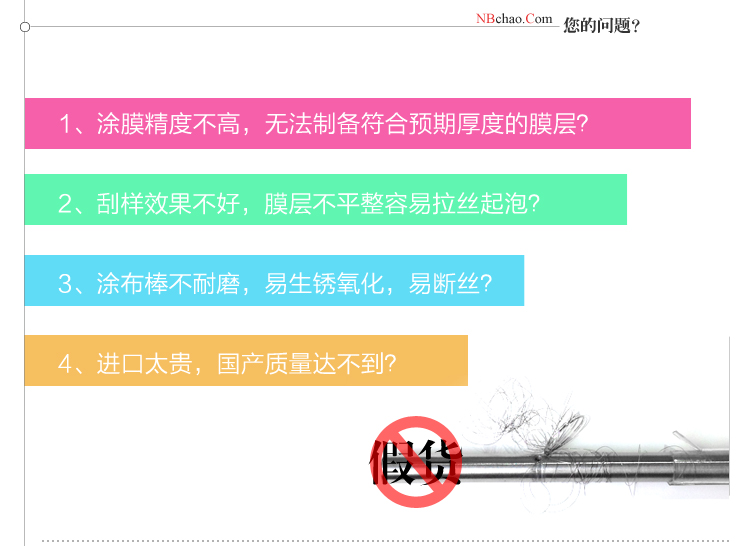

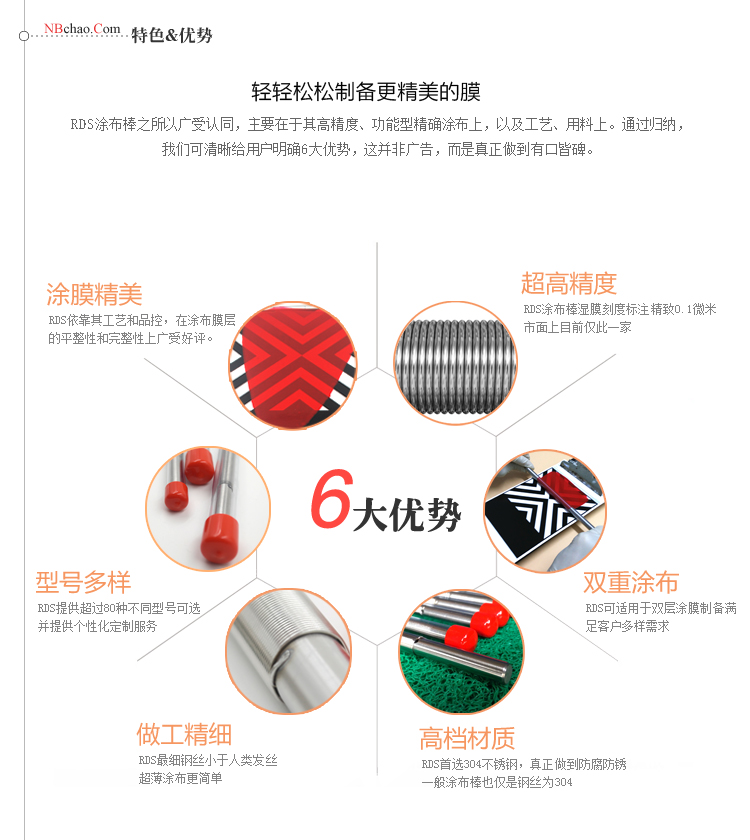

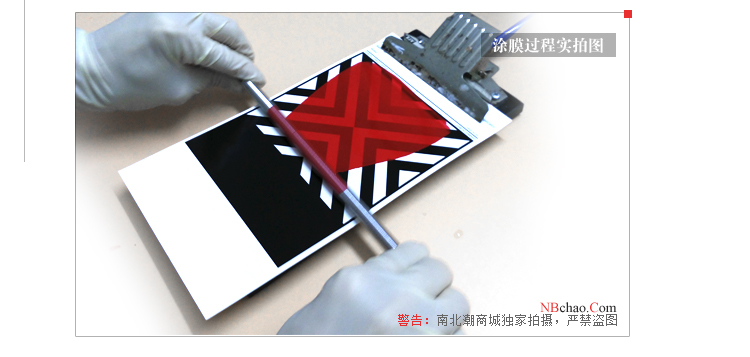

The RDS wire rod coater has 80 years of experience in the coating industry, and it has been more than 30 years since it was introduced into CHINA. The brand status in the coating rod industry is self-evident. It has always been recognized by the industry as a very good coating rod. It has mature experience and technology, the widest range of coating films, and the accuracy of the coating rod is as high as 0.1μm. No other company has achieved such high precision. The coating bar developed by RDS is easy to operate, and the high-grade stainless steel material makes it more durable. RDS Rod Coater - Undoubtedly a good coating rod, worthy of the user's favor. RDS #26 wire Bar Coater film thickness was 59.4 microns.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2HG/T 2006-2006《Thermosetting powder coatings》

- 3GB/T 1727-2021《General methods for preparation of coating films》

- 4GB/T 7044-2022《Colour carbon black》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 3355-2003《Various colour nitrocellulose primer》

- 8HG/T 3951-2007《Water based colorants for architectural coatings》

- 9HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 10GB/T 13217.1-2009《Test method for colour of liquid ink》

26# 1/4“

26# 1/4“