TQC VF2247 levelling sag with calibrating certificate

SETQC sheen VF2247 Levelling sagSPEC

TQC sheen VF2247 Levelling sagDetails

TQC sheen VF2247 Levelling sagPacking list

- SKU

- NB004598

- groove depth

- 0.25/0.5/1.0/2.0/4.0mm

- Groove depth (sag)

- 475/450/425/400/375/350/325/300/275/250μm

- material

- stainless steel

- Dimensions

- 15*28*100mm

- Weight

- 72g

- standard

- ASTMD4400、ASTM D2801

Introduction

There are two models, VF2246 and VF2247, the TQC leveling sagger, which is used for a simple comparison of leveling and sagging during the period from the completion of paint application to the drying of the paint film, one side is used to test the leveling, and can coat 5 film thicknesses, and the other side tests the sagging, and can coat 10 film thicknesses (75-300 microns).

The leveling sagging is a special Film Applicator with dual functions, and the single-sided test of the depression paint thickness ranges from 75 to 300 microns (one unit per 10 microns). The addition of 5 slots on the other side is to determine the thickness of the paint film when sagging is about to occur. The combined stripes can be used to evaluate the level of measurement.

The leveling saggers are made of stainless steel and are not affected by acids and other chemical elements.

Parameters

| Model | Leveling | Sag |

| VF2246 | 0.25,0.5,1,2,4 | 300,275,250,225,200,175,150,125,100,75 |

| VF2247 | 0.25,0.5,1,2,4 | 475,450,425,400,375,350,325,300,275,250 |

| Unit: mm, μm | ||

| Other parameters | ||

| standard | ASTMD4400、 ASTM D2801 | |

| Material | stainless steel | |

| size | 15x28x100mm | |

| weight | 72g | |

Introduction to paint leveling

The so-called leveling of the coating refers to the smooth state of the coating film after the construction of the coating, and the surface with good leveling should not have irregular forms such as orange peel, brush marks, corrugations, and shrinkage holes. Usually the method of direct observation with the naked eye is to compare the sample with the standard sample in parallel to judge the quality of the leveling of the coating film, which varies from person to person and is highly subjective.

The use of Sag and Levelling Film Applicator can more accurately and effectively judge the quality of the leveling of the coating film.

Definition of leveling sag

In general, leveling is a performance requirement of quality personnel for paint, which is manifested in the surface of the dry film as smooth as possible, and as little surface brush marks, spray spots and other uneven phenomena as possible. Sagging, on the other hand, is considered a defect in the paint, which often occurs on the vertical surface, edges and corners of the workpiece.

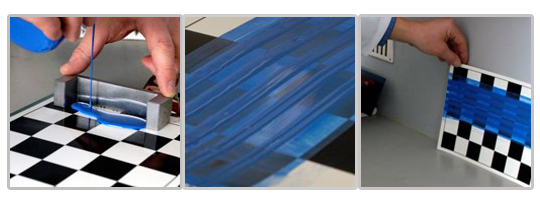

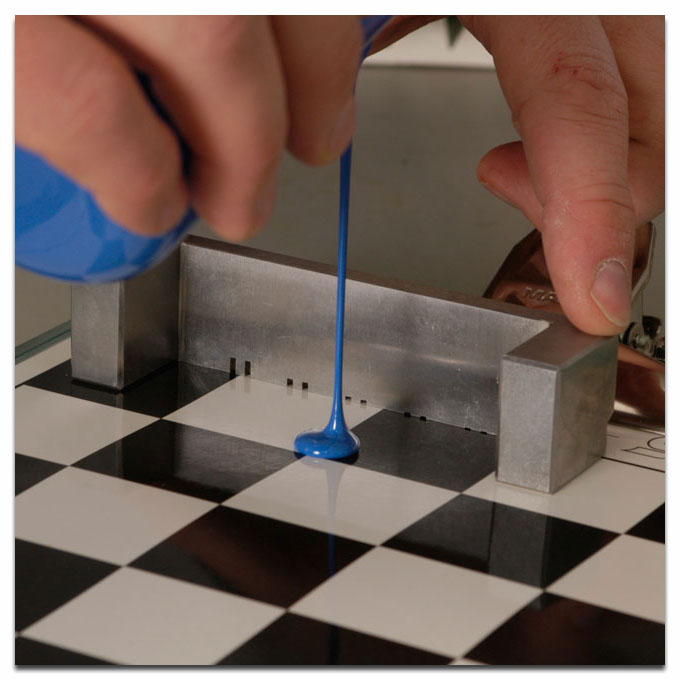

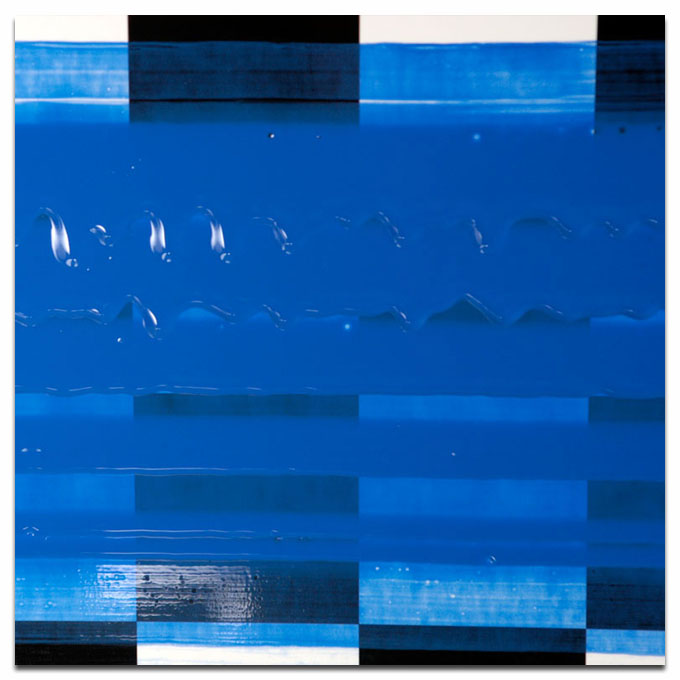

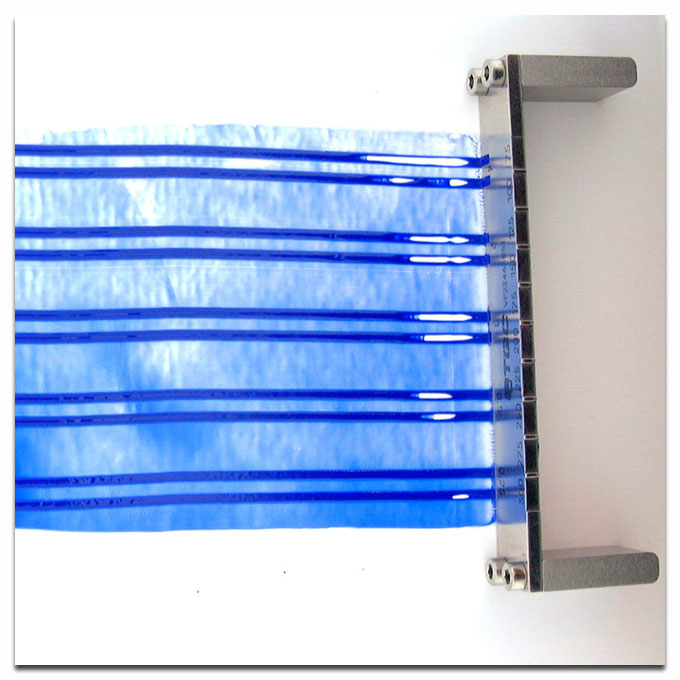

Practical diagram of leveling sag

Leveling and Sag Applicator on display

Actual picture of the product

Take you to the Dutch TQC

- 1what is the coating Leveling and Sag resistance

- 2Coating leveling and sagging

- 3Rheological performance of Coating industrial antisagging agent

VF2247

VF2247