KOSON KS-71G Integrated Rebar Scanner (English version) Range 1~ 185mm

SEKOSON KS-71G Integrated steel bar scannerSPEC

KOSON KS-71G Integrated steel bar scannerDetails

KOSON KS-71G Integrated steel bar scannerPacking list

- SKU

- NB045994

- Application range of protective layer thickness (mm)

- ϕ 6~Ф50

- Test range (mm)

- The first range: 1~ 90; the second range: 5~ 185

- Protective layer thickness MPE (mm)

- ±1(1~70);±2(60~100);±4(80~180)

- Diameter measurement application range (mm)

- ϕ 6~Ф50

- Maximum error of diameter measurement (specification)

- ±1

- scan mode

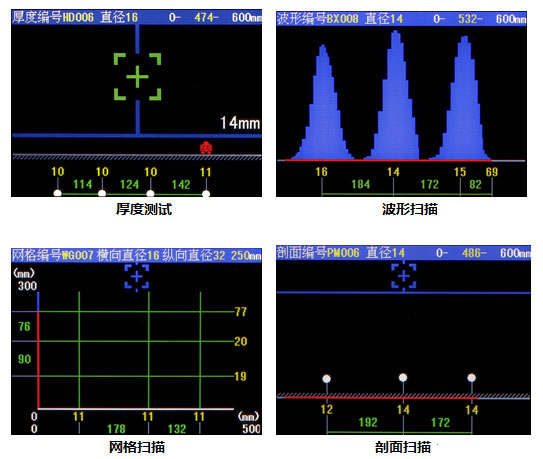

- Thickness mode, grid view, profile mode, waveform mode, JGJ detection

- Scanning range

- borderless

- data transmission mode

- USB

- Display

- 2.8-Inch high-resolution color LCD screen (320 × 240 pixels)

- Power Supply

- Built-in high-Capacity lithium battery

- Set the shutdown time

- 5m、10m、15m、30m、60m、90m

- With error correction

- Error correction range: -3.0~ + 3.0 (i.e. +/- 0.5, +/- 1.0, +/- 1.5, +/- 2.0, +/- 2.5, +/- 3.0)

- Key mode

- Silicone keyboard

- Operating temperature

- -10℃~+42℃

- Volume (mm)

- 219×92×106

- Weight

- 0.6kg

Overview

KS-71G is mainly used for testing the position of reinforcement inside, the thickness of the protective layer, the spacing of reinforcement and the diameter of reinforcement in concrete structure, and can accurately draw the distribution map of the overall reinforcement and quickly provide high-precision detection data.

Scope of application

◆ Detection of the position of reinforcement, distribution and direction of reinforcement, thickness of protective layer and diameter of reinforcement in concrete structure engineering;

◆ Acceptance and inspection of the construction quality of concrete structures of buildings;

◆ Detection and detection of steel bars in bridges, tunnels and other structures;

◆ Evaluate the safety and durability of the structure under construction;

◆ Evaluate the old structure and detect the amount of reinforcement during the transformation.

According to the standard

◆Code for Acceptance of Construction Quality of Concrete Structure Engineering GB 50204-2015

◆Technical Standard for On-site Testing of Concrete Structures GBT50784-2013

◆ Technical Regulations for Detection of Steel Bars in Concrete JGJ/T152-2008

◆ Technical Standard for Building Structure Detection GB/T50344-2004

◆ Technical specification for detecting the thickness of the protective layer and the diameter of the reinforcement by electromagnetic induction method DB11/T365-2006

◆ "Specification for Measurement and Calibration of Thickness Measuring Instrument of Reinforcement Protective Layer and Thickness Measuring Instrument of Floor Slab" JJF1224-2009

Featured Functions:

Each detection mode is intuitive and accurate, and accurately displays the position, spacing, and thickness of the protective layer on the same display screen.

Single-point measurement, grid scanning, waveform scanning, and profile scanning are all fully realized, and the data and graphics can be viewed after turning the page back and forth at will during the measurement process, and the test data with incorrect operation can be deleted at any time, which is convenient for on-site testing;

The JGJ detection mode realizes 1-6 repeated tests of a single steel bar, and automatically calculates the average value;

During the test process, the grid scanning completely realizes the arbitrary staggered switching of the X axis and the Y axis (i.e., the direction of the vertical and horizontal axis axis) test, which does not affect the test data;

After switching at will, the data and reinforcement distribution diagram will automatically continue the previous information for testing, so as to improve the flexibility of on-site testing.

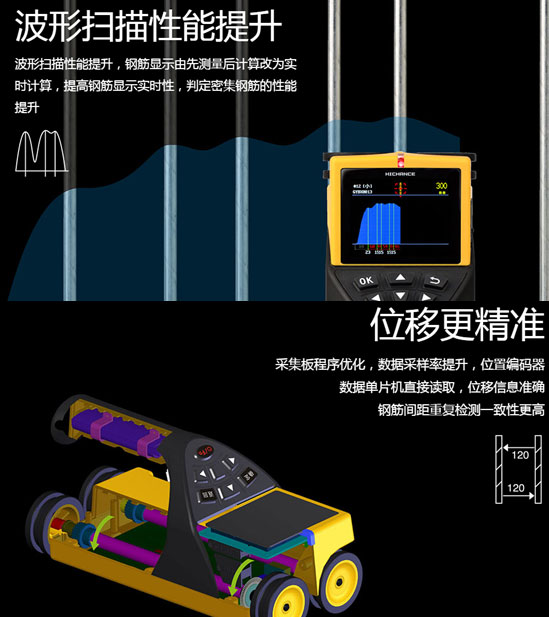

It adopts one-hand grip machine, operation design and four-wheel alignment, and is equipped with high-strength wear-resistant tires to protect the wear of the instrument

The automatic storage of calibration values enables fast measurements and eliminates the need for troublesome procedures for each calibration work before inspection.

Features

2.8-inch high-resolution color LCD screen (320×240 pixels), detection data can be clearly seen in any situation indoors and outdoors;

Multi-coil structure design, faster speed, higher precision, stronger resolution;

Using USB mode data transmission and charging, the stored data can be quickly uploaded to the computer through the USB cable;

It adopts a built-in large-capacity lithium battery, which is designed to have low power consumption, and can be used for about 16 hours when the battery is fully charged.

In the data management mode, the functions of data storage, viewing, and deletion can store about 200,000 steel bar measurement point data;

It has the ability to distinguish super-dense reinforcement to solve the problem of missing steel bar;

It can be equipped with a standard calibration test block with a professional and unique design;

It adopts the integrated design of the host and the sensor coil, which is small in size, light in weight and easy to carry;

The middle position of adjacent steel bars is judged in real time, and the indicator light prompts that it can avoid the surrounding steel bars and facilitate drilling and coring;

The protective lining of the instrument box adopts a unique and novel ladder and cylindrical diversion groove, which is convenient for the instrument to be put in.

Equipped with steel bar detection software, it is convenient to conduct professional data analysis, data processing and generate complete reports on the PC.

Instrument interface

Benefit Assessment:

KS-71G

KS-71G