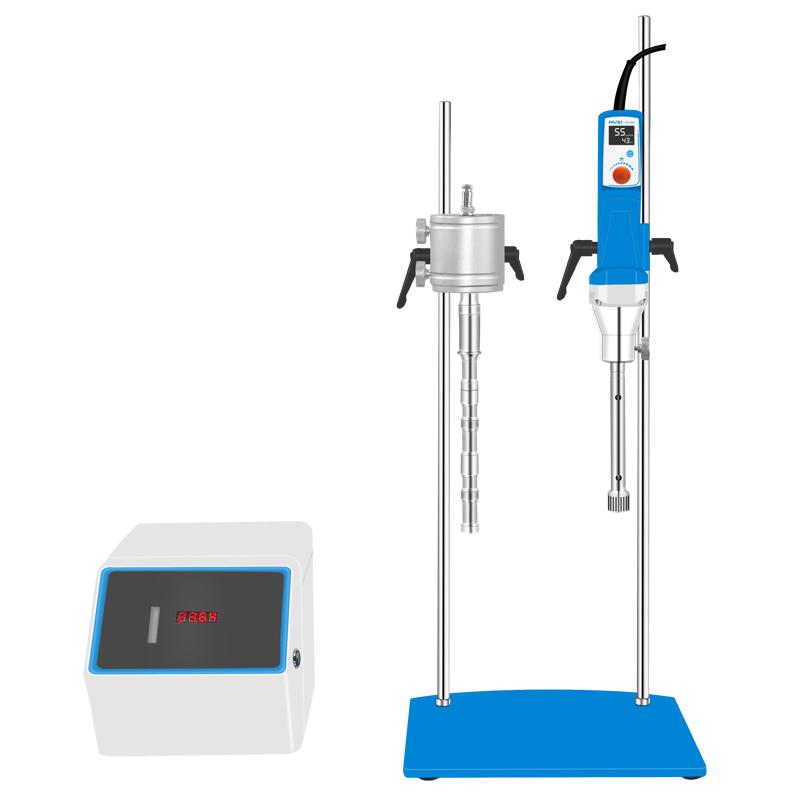

HUXI HXR-2000 High Speed Ultrasonic Mulser 10L/2000W

SEHuXi HXR-2000 High Speed Ultrasonic MulserSPEC

HuXi HXR-2000 High Speed Ultrasonic MulserDetails

HuXi HXR-2000 High Speed Ultrasonic MulserPacking list

- SKU

- NB046591

- Power Supply

- 220V/50-60Hz

- Power

- 2000W

- Drive mode

- piezoelectric ceramics

- show

- Touch screen display

- Temperature display

- -10~199℃

- adjust

- Power 30~100% adjustable

- Work head material

- Titanium alloy T1-6AL-4V, amplitude ratio: 1:1.5 Category: Exponential

- Specifications

- Diameter 25-35mm

- Work head type

- exponential

- Minimum immersion depth

- 150-300mm

- Emulsification display

- LCD display

- Emulsification Input Power

- 1050W

- Emulsification output power

- 750W

- Drive motor

- Brushless DC motor, can work continuously

- Emulsification speed

- Rotation speed 4000-26000rpm adjustable

- Emulsification head material

- 304/316L optional

- Maximum shear speed

- 47m/s

- Diameter of emulsification head

- Stator outer diameter 30mm

- Processing samples

- Suitable for Paste, Fiber, Liquid, Resin

- Cable length

- 150cm

- Fuse Specifications

- 20A

- Processing Capacity

- 2L-10L

Introduction

HXR-2000 high-speed phacoemulsifier is a professional processing equipment that combines ultrasonic vibrator and high-speed emulsifier integration, which is used for large dispersed sample capacity, pilot test and high sample concentration; Its energy output is superior to that of an ultrasonic disperser and an emulsifier, so the direction of use is more flexible, and the integrated equipment can effectively process large volumes, high concentrations, high viscosity and poor fluidity samples. It is widely used in graphene, silicon oxide, carbon nanotubes, gels, resins and other fields.

Features

The ultrasonic controller adopts self-developed circuits, the working Voltage of the ultrasonic generator device is 220V/AC, and the ultrasonic circuit appliances have overVoltage, overcurrent, output short circuit and other protection measures;

The ultrasonic circuit has automatic frequency tracking, and the frequency is automatically tracked at the resonant point suitable for the output, so that the transducer always works in a good state, the energy conversion efficiency reaches the maximum, and good results can be achieved under different Operating Conditions;

The ultrasonic controller has the function of power adjustment, and the output power can be continuously adjusted to meet the requirements of various sample objects;

It is equipped with a display of working status, which is convenient for observing the working status of the ultrasonic controller;

30JX special high-shear working head, which can meet the processing capacity of 2L-10L, and is suitable for different sample processing requirements;

The whole machine has a compact structure and exquisite shape, providing a linear speed of 47m/s for sample homogenization;

The two-way support rod design combined with the double-hole position clamp forms an integrated lifting adjustment system, making your experiments reliable and safer;

It can be equipped with a temperature sensor to measure the sample temperature in real time, reach the set value, and automatically stop the operation, so as to better protect the sample and make the experiment safe and secure

HXR-2000

HXR-2000