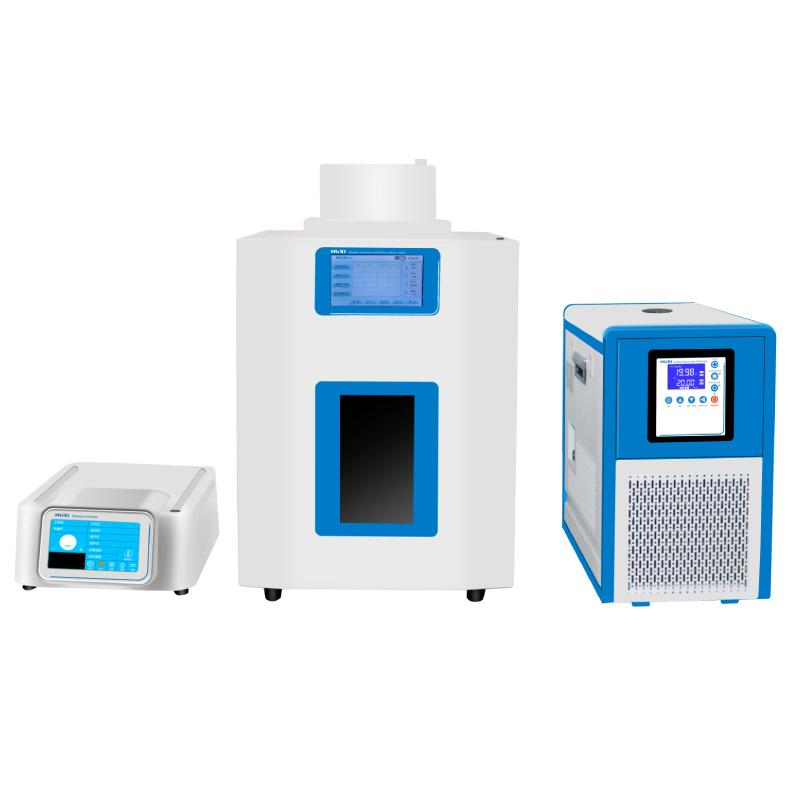

HUXI HX-CW2000H Ultrasonic and Microwave Combined Reaction System, Wireless Infrared 2000ml

SEHuXi HX-CW2000H Ultrasonic microwave combined reaction systemSPEC

HuXi HX-CW2000H Ultrasonic microwave combined reaction systemDetails

HuXi HX-CW2000H Ultrasonic microwave combined reaction systemPacking list

- SKU

- NB046923

- container Capacity

- 2000ml

- Ultrasonic Power

- 1800W can be fine-tuned

- Ultrasonic horn

- Random: φ 25

- Ultrasonic Frequency

- 20KHZ

- Ultrasonic Display mode

- True color 7-inch touch capacitive screen high-definition display

- Ultrasonic Control mode

- MCU + TFT touch

- Ultrasonic host material

- Aluminum alloy + ABS plastic mold one-time molding

- Power of microwave reaction system

- 2100W

- Maximum output power of microwave reaction system

- 1000W

- Microwave Frequency

- 2450MH, 0-100% Power automatic continuous adjustable

- Microwave temperature sensor

- Wireless Penetrable Infrared Temperature Sensors

- Microwave temperature Measurement Range

- 0~350℃

- Microwave maximum temperature

- 250℃

- Microwave temperature control Accuracy

- ≤±1℃

- Microwave pressure Measurement Range

- 0-15Mpa

- Microwave Voltage control Accuracy

- ±0.01Mpa

- Microwaveoven cavity material

- 316L industrial grade stainless steel integrated molding

- Microwaveoven door material

- Buffer floating design six-story steel structure furnace door

- Working time

- Continuous work, 0-9999s adjustable

- Rotation speed

- 0~2500rpm

- Circulation pump model

- HXS-0503

- Circulation pump item number

- 1039019001

- Temperature range

- -5~100℃

- Digital resolution

- 0.1℃

- Inner tank Volume (length * width * depth)

- 170*180*130mm

- Flow rate of circulating pump

- 8L/min

- Filling port

- Φ35mm

- Tank Capacity

- 3.5L

- Circulation pump instrument size (depth * width * height)

- 440*300*510mm

- Microwave instrument size (L * W * H)

- 500*480*550mm

- Ultrasonic host instrument size (depth * width * height)

- 427*340*168mm

- Net Weight of circulating pump instrument

- 27.5kg

Introduction

The HX-CW2000H Ultrasonic and Microwave Combined Reaction System has microwave, ultrasonic, microwave ultrasonic independent control and synergistic functions. At the same time, the system realizes 7-inch touch interface control, data storage, and high-definition visualization real-time display of reaction status.

Microwave chemical synthesizers are widely used in chemical synthesis in universities, scientific research institutes, biopharmaceuticals, materials and mining and many other fields. The microwave chemical synthesizer uses the basic principles of microwave, ultrasonic, ultraviolet light and other basic principles to have an effective catalytic effect on the reactants, which can create a variety of synthesis conditions and accelerate the chemical synthesis reaction.

Features

1. Technical characteristics

1.1 Temperature control system: infrared temperature sensor.

1.2 Container capacity: 2000ml.

1.3 Operating system: microcomputer control technology, multi-segment program control mode.

1.4 Ultrasonic power: 1800W can be fine-tuned; Ultrasonic frequency: 20KHz, the ultrasonic probe can be used for interventional or non-interventional samples, acting on the sample function through cavitation effect or air transmission.

1.5 Standard ultrasonic probe diameter: Φ25 is suitable for different caliber reaction vessels

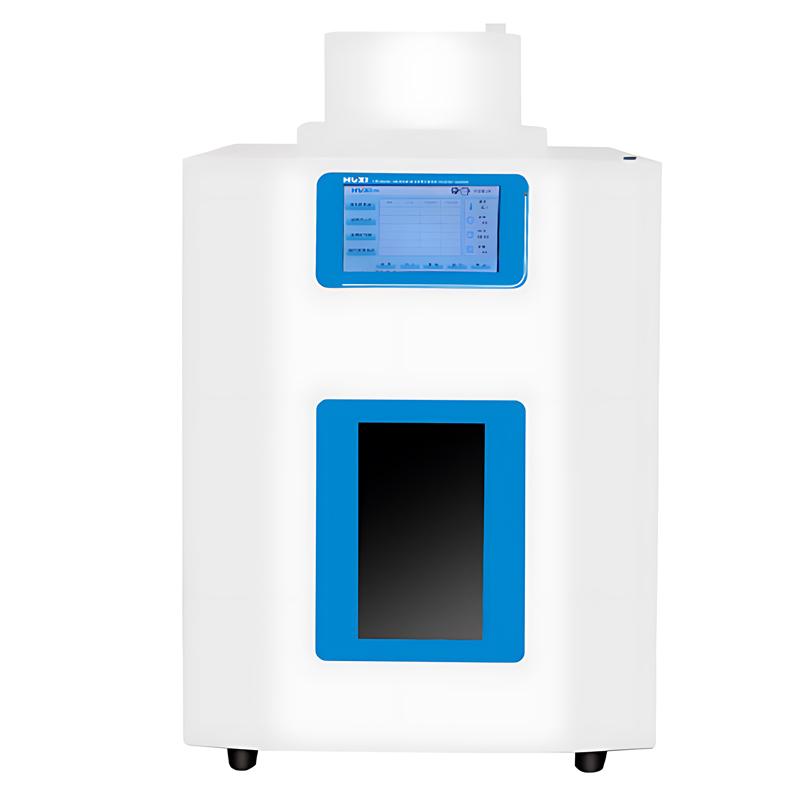

2. Control system

2.1 Microwave frequency: 2450MHz, non-pulse continuous automatic frequency conversion control, 0-100% power automatic and continuous adjustable.

2.2 Industrial-grade magnetron: microwave maximum output power 1000W.

2.3 Temperature control system: Platinum resistance temperature sensor with wired connection.

2.4 Ultraviolet catalytic system: wavelength 253.7nm, power 100W.

2.5 Stirring device: magnetic stirring, stirring speed 0~2500rpm adjustable.

2.6 Multi-function operation mode, which can be extended to microwave extraction, microwave synthesis, ultrasonic wall breaking, etc.

3. Safety of furnace door and furnace cavity

3.1 The six-layer steel structure safety furnace door adopts buffer floating design to ensure the safety during the experiment.

3.2 The mechanical lock and electronic lock are used to coordinate and cooperate to ensure that the furnace door cannot be opened during operation, and the instrument will automatically cut off the microwave and stop working when the furnace door is opened abnormally.

3.3 The furnace cavity is made of 316L industrial-grade stainless steel, and the furnace cavity is sprayed with up to 6 layers of PFA anti-corrosion coating.

4. Operating system

4.1 Microcomputer control technology, which can realize historical data viewing, data export and import.

4.2 Capacitive LCD touch screen, real-time display includes: temperature, heating time, constant temperature time, microwave power, reaction process.

4.3 The instrument has a built-in method library, which can directly select and call schemes, and can store 200 methods.

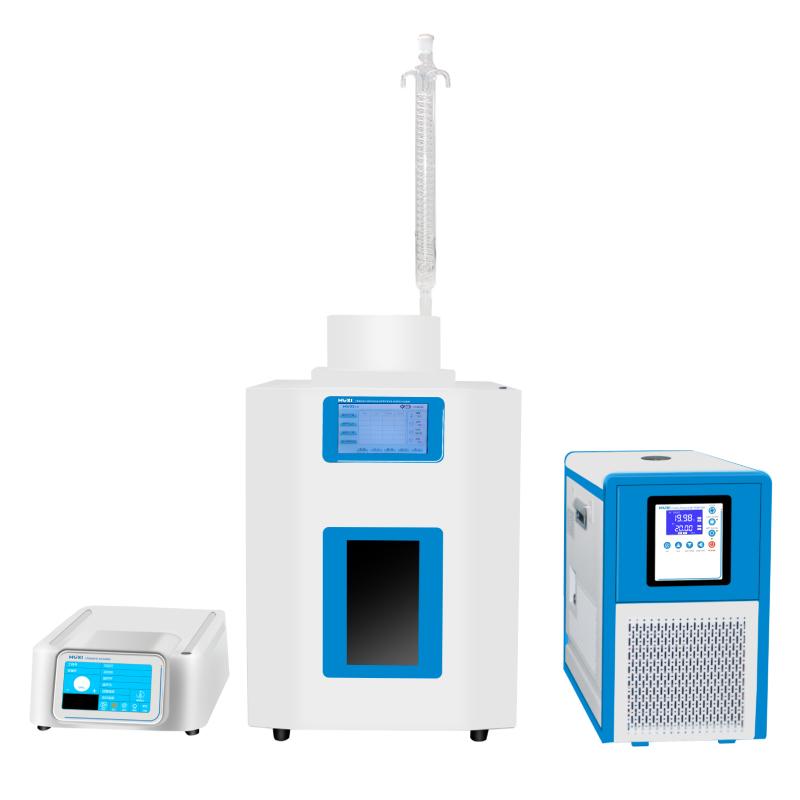

5. Reaction components

5.1 The reactor can be equipped with PTFE or high-temperature and corrosion-resistant glass materials, and the reactor volume is 2000ml.

5.2 The reactor can be connected to a glass conduit, and an open reaction system is adopted, and a drip funnel and condenser tube can be installed for reflux reaction.

HX-CW2000H

HX-CW2000H