CHINA immersion coil drying air-cooled slitting machine Rdc-01/500cs dipping coating machine

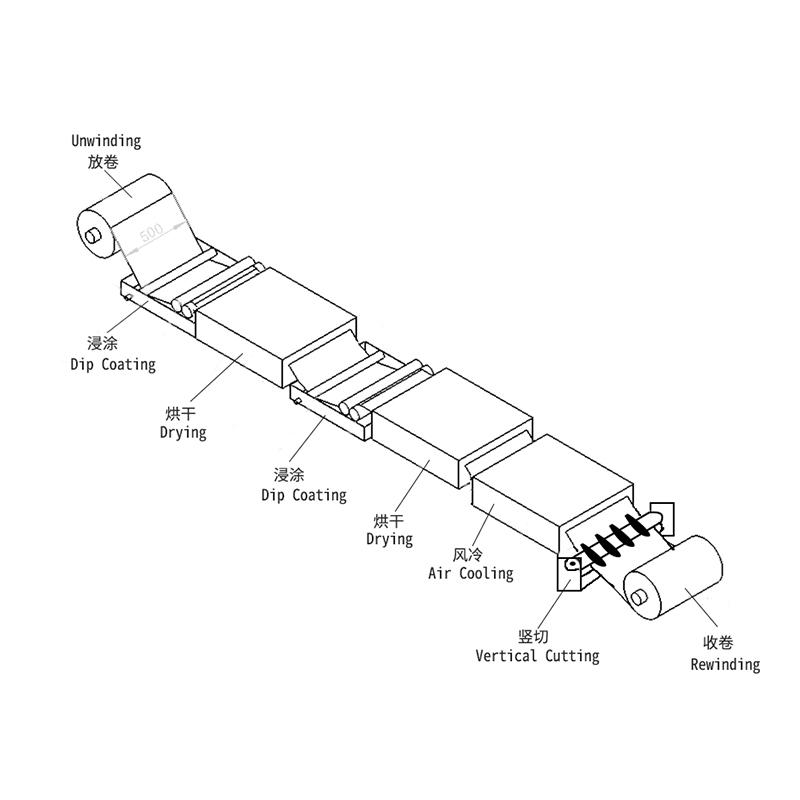

SEDip coating, unwinding → first dip coating → drying → second dip coating → drying → air-cooled → vertical cutting → winding, effective application width 500mm, special for melamine dipped paper experiment.

$34529.00/set

PromotionLoading...

Coupon

Model:

Factory

Factory Rdc-01/500cs Soaking coil drying air-cooled slitting machineSPEC

Factory Rdc-01/500cs Soaking coil drying air-cooled slitting machineDetails

Factory Rdc-01/500cs Soaking coil drying air-cooled slitting machinePacking list

- SKU

- NB047316

- main substrate

- Plain base paper or printing decorative paper

- glue

- Mixture of melamine formaldehyde Resin and urea formaldehyde Resin

- Spreader moisture

- Adjustable (formed) according to the process

- Coating method

- soak

- Coating size

- Max.500mm

- substrate

- Less than 500mm

- Roll surface width

- 500mm

- mechanical speed

- 1.2M/min (0.1~ 1m/min production speed, depending on the process) The speed can be adjusted slowly

- unwinding diameter

- ≤ φ 400mm (paper core 3 ")

- winding diameter

- ≤ 500mm (paper core 3 ")

- Heating drying method

- External infrared heating, centrifugal fan hot air circulation

- temperature control

- 50~150 ℃ +/- 3 ℃ (maximum 160 ℃ in the intermediate temperature zone)

- Curl the edges neatly

- ±3.0mm

- Total Installed Power

- About 40kW (Power required for electric heating is about 35kW)

- Equipment external Dimensions

- (L x W x H) According to process changes and final design drawings

- Teflon roller

- 4 pieces (installed in front of the Spreader head respectively)

- Power Supply

- Three-phase five-wire 380V 50Hz

- Unwinding Unit - Type

- Single station

- Unwind Unit - Effective Unwind Width

- 500mm

- Unwinding Unit - Effective Unwinding Diameter

- ≤Φ400mm

- Unwinding Unit - Unwinding Scroll

- 3 " (φ 76mm) 1 piece of inflatable shaft (suspended structure)

- Unwinding Unit - Unwinding Tension Control

- Tension automatic control, magnetic particle brake, tension Controller

- Front Traction Unit - Steel Roller

- Φ42x500mm

- Front Traction Unit - Motor

- SEND/0.75KW (servo control)

- Chilling down device

- air-cooled

- Cutting device

- 3 air knives, you can freely control the cutting spacing

Rdc-01/500cs

Soaking coil drying air-cooled slitting machine

Dip coating, unwinding → first dip coating → drying → second dip coating → drying → air-cooled → vertical cutting → winding, effective application width 500mm, special for melamine dipped paper experiment.

This machine is mainly suitable for the process of melamine dipped paper.

Equipment process

Unwinding → first dip coating → drying → second dip coating → drying → air cooling → vertical cutting → winding (effective coating width 500mm)

Main part configuration

(1) Unwinding unit (1 group in total)

Structural features:

Type: single station

Effective unwinding width: 500mm

Effective unwinding diameter: ≤ φ 400mm

Put the reel: 3 " (0019 76mm) 1 piece of inflatable shaft (suspended structure)

Unwinding tension control: tension automatic control, magnetic powder brake, tension controller

Specifications:

Unroll main configuration:

Magnetic powder brake:

Tension controller:

Inflatable shaft: 3 "/cantilever type (winding part)

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

Knowledge

- 1List of experimental testing instruments for research and development of nano-composite water-based barrier coatings

- 2Some theory you need to know about the dip coating process

- 3What are the requirements for preparing test samples for aqueous dip paint?

- 4Dip coating process and dip coating machine

- 5This article takes you into the technical field of immersion coil coater

- 6What is leveling? What parameters affect leveling?

- 7Advantages and disadvantages of dip coating process and ideal use

- 8Operation Flow of Polymer Electrodeposition

- 9Diversity and applicability of Coating painting methods

- 10How to troubleshoot dip coating defects?

Standard

Rdc-01/500cs

Rdc-01/500cs