DUBAN DB25-204WPM 100KN Portable welding stress testing instrument Measurement range +/- 98000N

SEDuban DB25-204WPM 100KN Welding stress testing instrumentSPEC

Duban DB25-204WPM 100KN Welding stress testing instrumentDetails

Duban DB25-204WPM 100KN Welding stress testing instrumentPacking list

- SKU

- NB047461

- Display type

- digital display

- Measurement range

- ±10000kgf、±98000N、±22000Lbf

- Precision

- Level 0.2

- error of indication

- +/- 0.2% FS (range) +/- 1 digital peak

- Power Supply

- 2 AA batteries or 5V DC Power Supply

- Dimension

- Main body: 199mmx76mmx37mm, probe: 268mmx φ 44.6mm

- resolution

- 0.01kgf (<100kgf) 、0.1kgf (≥100kgf);0.1N (<1000N)、1N (≥1000N);0.1Lbf (<1000Lbf) 、1Lbf (≥1000Lbf)

- unit

- kgf, N, Lbf

- Measured value

- Peak, instantaneous value

- Display

- LCD screen

- Backlight

- Blue Backlight

- allowable load

- 150% FS (when it exceeds 110% FS, there will be a beep alarm)

- Operating temperature

- 0°C~40°C

- Operating humidity

- < 80%

- Operating Environment

- No source and corrosion medium around

Introduction

The welding pressure Tester adopts a microcomputer digital display instrument. It has input terminals for dynamometer (pressure) and load cell (weight) strain gauges. It has been used in new static and dynamic measurement systems such as materials testing machines, printing machines, test benches and automation equipment. With a measurement accuracy of ≤±0.02%, it can be used in quality inspection systems for the first or second batch of samples for general calibration. The measurement system consists of an analog section, in particular a long-term stable analog part, a frequency feeder that reduces the thermal drift of the system and a 16-bit A/D converter that guarantees an internal division of 65.000.

Features

High precision and high resolution.

Digital display, no parallax.

N (Newton), kg (kg), lb (pound), three units of measurement can be selected, and they are converted to each other.

Peak hold function. Hold the peak display until it is manually cleared.

Can be powered by alkaline batteries; It can also be connected to a 5V DC power supply.

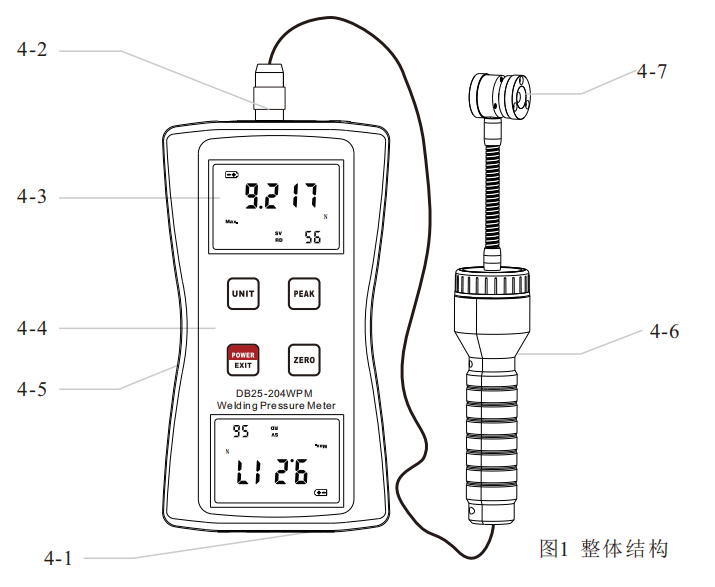

Product structure diagram

Structural function description

4-1 power interface: It can be connected to a 5V DC power supply to achieve DC power supply.

4-2 Sensor Plug: Used to connect the main unit to the sensor.

4-3 Display: Used to display measurement readings, units of measurement, prompts during operation, etc.

4-4 Operation button area: All the operation buttons are distributed, and the key operation of the entire instrument is completed here.

4-5 Battery box on the back: The place where the battery is installed to achieve battery power.

4-6 Handle: For hand grip and easy handling.

4-7 Measurement sensor: It can convert the received force information into an electrical signal and transmit it to the host computer.

DB25-204WPM 100KN

DB25-204WPM 100KN