Air-cooled curing coil Film Applicator Rgd-01/300cl Tape unwinding + scraping + air-cooled curing + overlay deviation correction + winding function

SE

Factory Rgd-01/300cl Air-cooled Curing Film ApplicatorSPEC

Factory Rgd-01/300cl Air-cooled Curing Film ApplicatorDetails

Factory Rgd-01/300cl Air-cooled Curing Film ApplicatorPacking list

- SKU

- NB047524

- Spreader head

- Drawdown blade

- compound speed

- 1-10M/min (slow compounding speed, step-by-step control, adjustable above 0.1m/min)

- composite width

- 100-300Mm adjustable

- WFT

- 0.005-3mm

- Device size

- About 1800X width 800X height 1600mm (customized products are for reference only)

- maximum discharge

- 300mm

- maximum charge

- 300mm

- Coating size

- Max.300mm

- Air-Cooled Curing Oven

- room temperature

- Curing Oven Length

- 1m

- Curing Oven Power

- 1KW

- Power/Power

- 220V/2.5KW

- motor

- Stepper motor

- Feed trough heating temperature

- Room temperature~ 200 ℃

Introduction

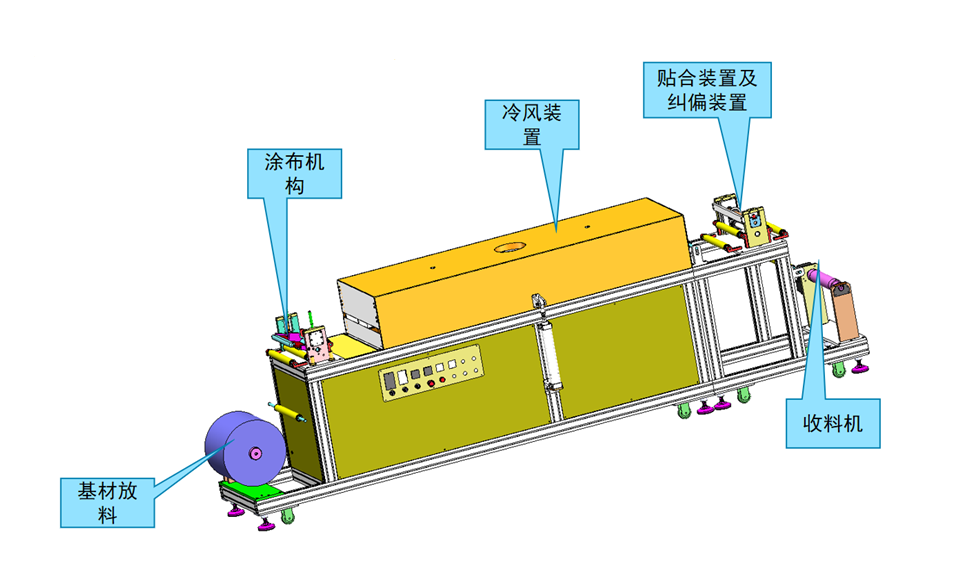

RGD-01/300CL air-cooled curing coil coating machine, with unwinding, scraping, air-cooled curing, film correction and winding functions, using anilox roller coating, coating width 300mm, feeding trough can be heated, 1 meter air-cooled curing box.

Product Structure

Oven coil composite coating machine is a multi-functional composite equipment, with the functions of unwinding, scraping, air-cooled curing, laminating and winding. The following is an introduction to the main structure of the device:

Unwinding device:The unwinding device is located at the beginning of the machine and is used to place the reels of the substrate to be compounded. It usually includes components such as reel holders, tensioning devices, and rollers to ensure stable conveying and tensioning of the substrate.

Scraping system:A key component of the coating process is the squeegee coating system, which uses anilox roller coating technology to evenly coat the molten polyethylene plastic on the surface of the substrate. The system consists of coating rollers, coating grooves, squeegee blades and rollers for precise coating control.

Air-cooled curing:The curing system is located after the squeegee coating system and is used to cure the material applied to the surface of the substrate, improving the quality and stability of the composite film. The curing system adopts the air-cooled curing method, which is a 1-meter air-cooled curing box.

Composite device:The laminating device is a key component that laminates the coating on the surface of the substrate with another layer of substrate. It usually consists of composite rubber rollers, compression rollers and heating devices to ensure the firmness and uniformity of the composite film. The heating temperature of the composite rubber roller can reach 200°C to ensure the good adhesion of the composite film.

Winding device:The winding device is located at the end of the machine and is used to collect the reels that have been compounded. It usually includes components such as a take-up device, a tensioning device, and a winding shaft, which can realize the stable collection and tensioning of the film reel, which is convenient for subsequent packaging and transportation.

Rgd-01/300cl

Rgd-01/300cl