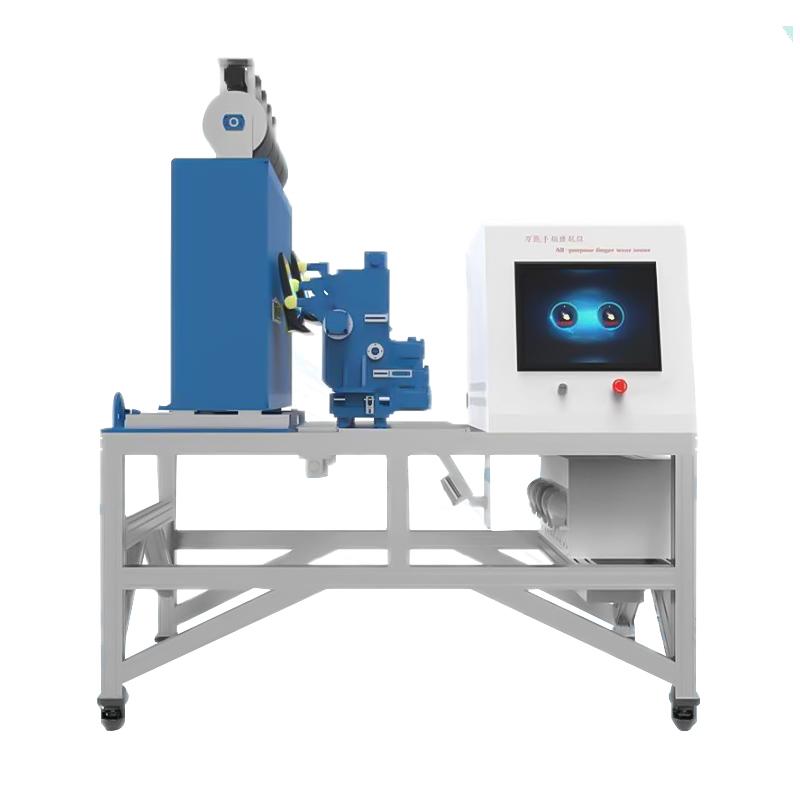

HUITAO HT-555 Five-station Finger Abrasion Tester Load 1N/5N/10N

SEhuitao HT-555 Five-station Finger Abrasion TesterSPEC

huitao HT-555 Five-station Finger Abrasion TesterDetails

huitao HT-555 Five-station Finger Abrasion TesterPacking list

- SKU

- NB048291

- Friction method

- vibration

- Frictional contact form

- point

- Test Travel

- 1-40Mm, friction angle is 45 degrees

- Power Supply

- 110V/230V

- Machine size

- 1650*1000*1850mm

- station number

- Five stations

- number of trials

- 1- 1 million times

- Test solution supply

- Fully automatic cycle

- Test woven fabric supply

- Automatic cycle

- fully automatic

- Fully automatic wear-resistant movement; X and Y axes are fully automatic feeding, using high-precision motors, which can be debugged

- Control system

- PLC

- Operating interface

- Color 7-inch touch screen, switch between Chinese and English

- conveyor function

- Added test automatic conveying function, can be debugged

- Liquid addition function

- Added automatic liquid filling function, using high-precision peristaltic pump to add liquid

- Level

- Configure level

- Friction Head Hardness

- 47 +/- 5 (Shore A Hardness)

- Friction head diameter

- 20Mm and 10mm

- Friction head contact surface diameter

- 20Mm and 10mm spherical surfaces

- Friction fabric

- Wool (supplies provided by customers)

Main uses:

The five-station finger abrasion testing machine can simulate the process of abrasion of most products and fingers and skin (finger abrasion, nail scratches, tooth abrasion, shoe sole abrasion and industrial scratches, etc.), and can realistically simulate the liquid environment, such as human sweat, hand cream, sunscreen, detergent, toothpaste and other liquid media.

Test principle

Automatic cyclic friction is performed at the angle specified by the standard by means of a test head, a certain amount of pressure, and a standard test cloth is carried out on the surface/coating of various materials, and the test conditions can be customized, including testing in dry and liquid conditions (sweat, emulsion).

Applicable Standards

IEC 68-2-70、DIN EN 60068-2-70、BMW GS 97034/GS 97045、Daimler DBL 7384、Ford WSS-M2P188-A1、EWIMA Specification、Sony Ericsson 45/152 41-FEA 202 8139 Uen、VW TL 226、DIN 53160-2:2001

Test items

1. Nail scratch resistance test: simulates the friction and scratches between human nails and the surface of materials (such as printing and painting);

2. Nail scratch test "for the automotive industry": simulates industrial scratches according to various test standards to evaluate the quality of coatings;

3. Sole abrasion test: test the abrasion resistance of the material against the sole according to various inspection standards;

4. Tooth simulation test: simulate the wear resistance of tooth materials according to test standards;

5. Fingerprint test: an affinity test of fingerprints and their cleaning characteristics.

HT-555

HT-555