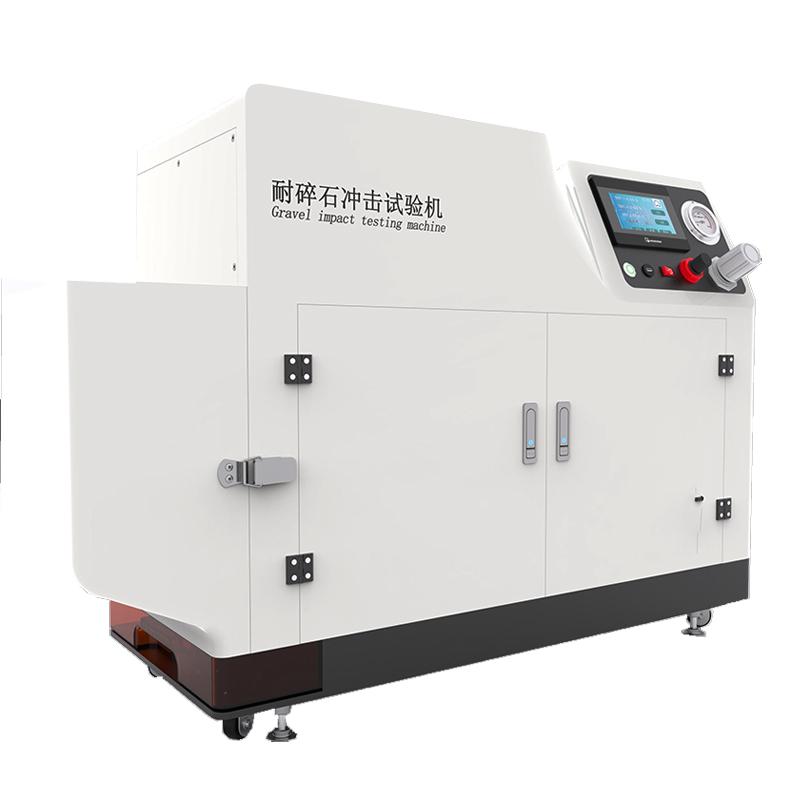

HUITAO HT-201 Crushed Stone Impact Tester Automotive coating anti-rock Tester, high-end version

SEhuitao HT-201 high-end version Gravel Impact TesterSPEC

huitao HT-201 high-end version Gravel Impact TesterDetails

huitao HT-201 high-end version Gravel Impact TesterPacking list

- SKU

- NB048307

- Control system

- PLC

- Operating interface

- Switch between Chinese and English;

- test software

- Free remote upgrade

- injection area

- All samples are set to the injection area.

- injection time

- Can be set for 0-999 seconds and set the time pause time during injection

- funnel

- Made of stainless steel, about 0-10 kg of spray medium can be installed

- 3D test chamber

- SAE 45 ° Impact Box and VDA 90 ° Impact Box 2-in-1, no need to replace, 90 °, 54 °, internal anti-collision soft material

- Vibration system

- Equipped with pneumatic vibration system

- jet medium

- Steel balls, pebbles, grit, etc

- Specimen size

- Width ≤ 195mm Thickness ≤ 35mm Length ≤ 240mm (can be equipped with different fixtures and sample sizes according to different products)

- Jet speed

- Adjustable 0-1MPA

- emission

- Adjustable, the opening can be adjusted arbitrarily

- crushed stone diameter

- 6mm

- Pressure adjustment range

- 0-1000kPa

use

Equipment for anti-grit and gravel crash tests of automotive materials and their surface coatingsThe gravel impact testing machine is especially designed for the anti-grit and crushing of automotive materials and their surface coatingsStone crash test and designed and manufactured.

Specimen and standard to be measured

Active grille, camera, glass, painted parts, headlights, etc

GMW 1407,JIS M0141,TL211-6,GME 60 268,ASTM/D3170,SAE J400,FORD,Chrysler 463PB-39-01,GMW14668-3.4.9,Chrysler 463PB-52-01,GM 9119P/9508P/9619P,Mazda MES MN 601C,Nissan,Volkswagen,Toyota,ISO 20567-1

peculiarity

PLC control system

The operation interface is switched between Chinese and English

The test software can be upgraded remotely and free of charge

The specimen is all set to the injection area

The spray time can be set from 0 to 999 seconds, and the time pause time can be set during the spray

The funnel is made of stainless steel, and can be installed with about 0-10 kg of injection medium

The control system and the specimen box are detachable, flexible, and can be moved at will

3D Test Chamber, SAE 45° impact chamber and VDA 90° impact chamber in one, no need to replace, 90°, 54°, internal anti-collision soft material

It is equipped with a pneumatic vibration system

Specimens can be equipped with different grips and specimen sizes according to different products

THE INJECTION SPEED IS ADJUSTABLE FROM 0-1MPA

The emission volume can be adjusted, and the opening can be adjusted arbitrarily

HT-201 high-end version

HT-201 high-end version