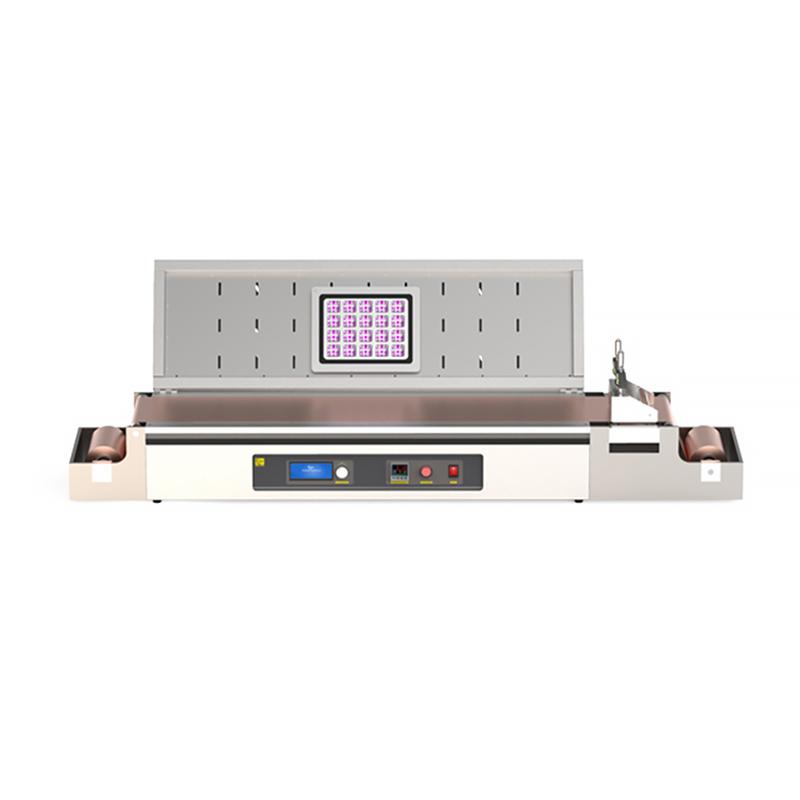

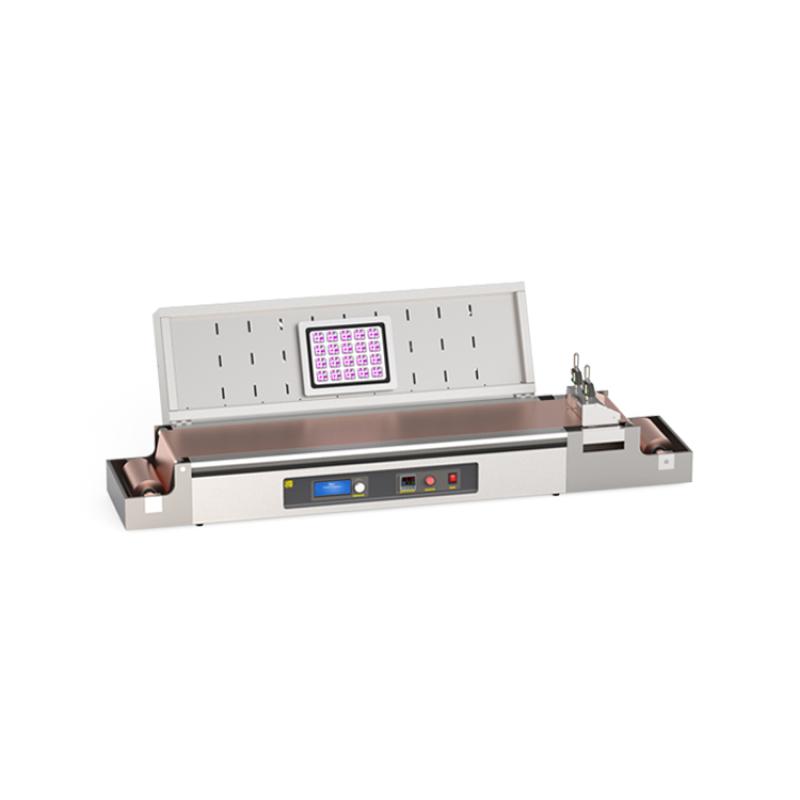

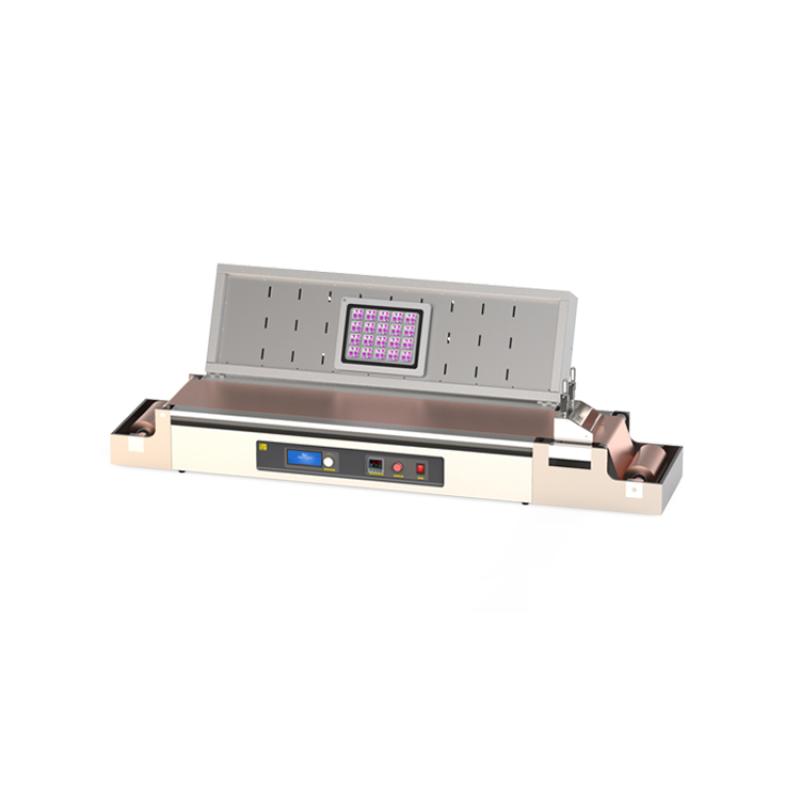

Chengyue CY-CMF-360 × 200B-S roll-to-roll casting coater

ChengYue CY-CMF-360×200B-S Roll-to-roll cast coaterSPEC

ChengYue CY-CMF-360×200B-S Roll-to-roll cast coaterDetails

ChengYue CY-CMF-360×200B-S Roll-to-roll cast coaterPacking list

- SKU

- NB048315

- Heating power

- 3000W

- Total Power

- 3100W

- Coated suction plate size

- 360mm X 200mm

- Film thickness Accuracy

- ±0.01mm

- Drawdown blade Moulding machine

- 300Mm wide

- rewinding mechanism

- Rotation speed of rewinding and unwinding mechanism is adjustable from 1~ 400mm/min, and the mechanism adopts feedback adjustment, which can automatically correct Rotation speed deviation

- Top UV

- Wavelength 365nm

- Temperature control Accuracy

- ±1℃

- Machine size

- 1245Mm X 500mm X 270mm (close protective cover) 1245mm X 550mm X670mm (open protective cover)

- Net Weight

- About 100kg

- vacuum pump

- Mechanical pump FY-4C-N

- pumping rate

- 4m3/h

- Exhaust port

- φ 8 quick screw joint

This small automatic drying coating machine is mainly used for laboratory coating liquid or colloidal film, the equipment uses a stepless variable speed motor to control the coating speed, to achieve the purpose of advancing the scraper at an even speed for coating, the scraper is made of stainless steel, with a constant weight, which can improve the consistency and uniformity of the coating film. The equipment adopts a bottom vacuum to adsorb samples, and has a bottom heating function, the heating temperature can reach up to 120 °C, and the function of baking the film is realized at the same time during the coating process, so that the film can be dried quickly. At the same time, the equipment is equipped with a rewinding and unwinding device, which can be used for continuous coating of copper foil or aluminum foil. The upper cover is equipped with a UV curing lamp, which can be used for curing and drying the film layer. This device is well suited for the continuous production of battery electrode materials.

CY-CMF-360×200B-S

CY-CMF-360×200B-S